Coating plays an indispensable role in industry and daily life. Whether it is protecting materials or beautifying surfaces, it is inseparable from the application of Coating. However, in the Coating industry, a key performance parameter is often overlooked, and that is the minimum film forming temperature (MFFT). This article will discuss in depth the concept, influencing factors and measurement methods of minimum film forming temperature (MFFT), and introduce an advanced instrument - minimum film forming temperature (MFFT) meter, its Application in Coating research and production.

Importance of minimum film forming temperature (MFFT)

The film formation process of Coating is one of the cornerstones of Coating performance, and the minimum film forming temperature (MFFT), as one of its important parameters, affects the performance of Coating at different temperatures. Minimum film forming temperature (MFFT) refers to the lowest temperature at which Coating begins to form a continuous film under certain conditions, and can also be understood as the temperature at which Coating can effectively adhere to the substrate. This parameter is directly related to the performance of Coating in a low temperature environment, such as Coating adhesion and durability.

Influencing factors

The minimum film forming temperature (MFFT) is affected by many factors, among which the composition of Coating and environmental conditions are one of the most important factors. The Glass transition temperature (Tg) of the polymer in Coating is an important parameter affecting the minimum film forming temperature (MFFT). The higher the Tg, the higher the minimum film forming temperature (MFFT). In addition, the type of additives in Coating, particle morphology, Environmental temperature and Humidity will also affect the minimum film forming temperature (MFFT).

Testing instrument

1. minimum film forming temperature (MFFT) meter

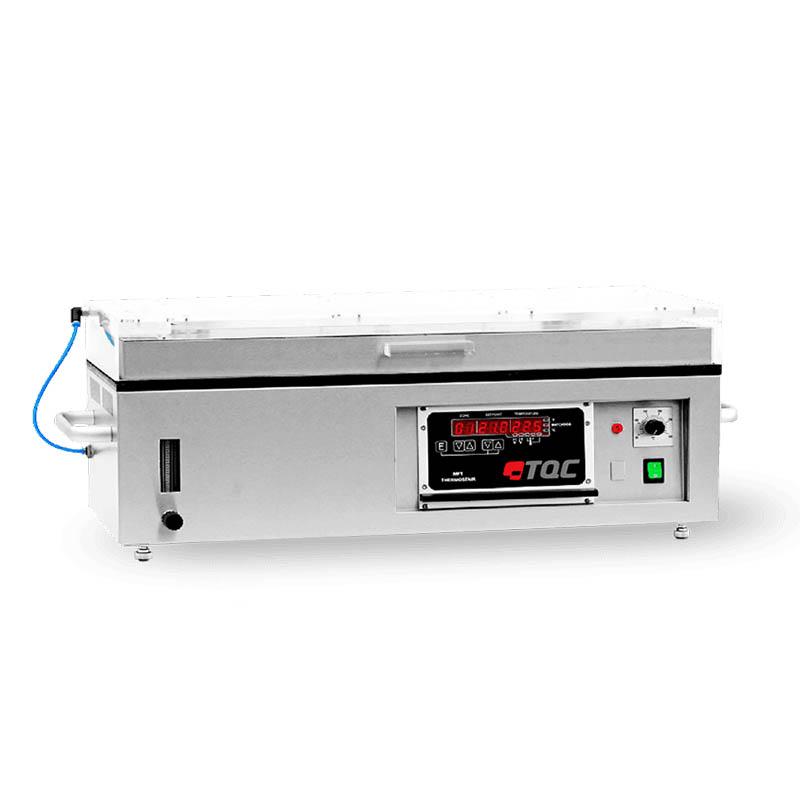

In order to accurately determine the minimum film forming temperature (MFFT) of Coating, scientists designed and manufactured a minimum film forming temperature (MFFT) meter. This instrument was developed on the basis of the national standard GB9267-2008 and is a new generation of paint film testing instrument. Its core composition is a temperature layer plate made of stainless steel. Through the action of cold and heat sources, an obvious temperature layer is formed on the temperature layer plate, thereby simulating the film formation process of Coating under different temperature conditions.

2. How to use and precautions

Using a minimum film forming temperature (MFFT) meter requires a series of steps and precautions. Before the formal test, prepare the instrument, including checking Encasement, placing the instrument, connecting power and water, etc. During operation, it is necessary to set cooling and heating presets according to the test conditions, preheat the instrument, place the Coating Spreader to be tested on the temperature layer plate, and observe the formation of the film formation boundary. In addition, pay attention to Environmental temperature, Humidity and power requirements, etc.

3. Application of minimum film forming temperature (MFFT) meter

The minimum film forming temperature (MFFT) meter has a wide range of applications in Coating research and production. It can help researchers understand the film formation characteristics of different Coatings at different temperatures, providing an important reference for Coating selection. In addition, the instrument also plays a key role in Coating process improvement, helping engineers optimize Coating formulations and construction conditions to improve Coating applicability and performance.

Summarize

As an important indicator of Coating performance, minimum film forming temperature (MFFT) plays an important role in the Coating industry. The development and application of minimum film forming temperature (MFFT) measuring instrument provides us with an accurate and reliable method to evaluate the film formation characteristics of Coatings. By deeply understanding the concept and measurement method of minimum film forming temperature (MFFT), we can better select and use Coatings, and also promote the continuous innovation and development of Coating technology.