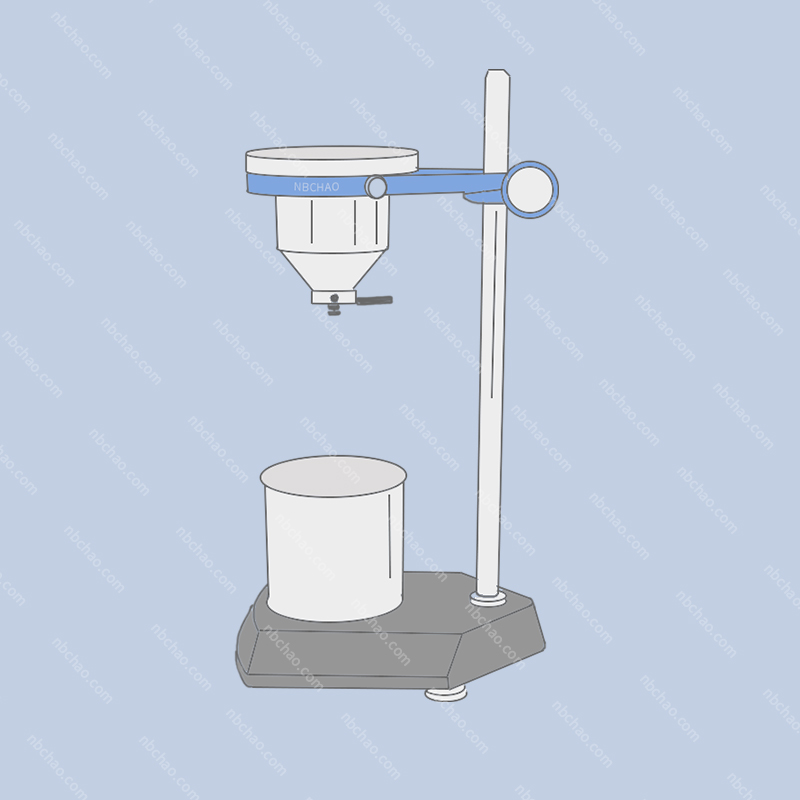

Abstract: As a commonly used Coating viscosity measurement tool, coating -4 Viscosity Cup needs to be calibrated regularly during use to ensure the accuracy of measurement results. This paper introduces three coating -4 Viscosity Cup calibration methods: kinematic viscosity method, standard Viscometer method and Engra condition method, and expounds the steps and principles of each method in detail.

1. Introduction

As a commonly used viscosity measurement tool in the Coating industry, the Tu-4 Viscosity Cup is widely used in production and quality control processes. However, to ensure that the measurement results of the Tu-4 Viscosity Cup are accurate and reliable, regular calibrating is required. The calibrating process can be carried out in a variety of ways, and this article will introduce three common calibration methods.

2. Kinematic viscosity method

The kinematic viscosity method is a calibration method in which the kinematic viscosity of different standard oils is determined by using a capillary tubing Viscometer, and then calibrated at a specific temperature using a standard oil with known kinematic viscosity. Based on the kinematic viscosity of the standard oil, the standard outflow time T for coating -4 Viscosity Cups can be calculated. By measuring the outflow time t, the correction factor K can be calculated as follows:

T = 0.223v + 6 (23s ≤ T < 150s)

T = 0.154u + 11 (T < 23s)

Where T is the standard outflow time, v is the kinematic viscosity, and t is the measured outflow time. The final correction coefficient K is the average of a series of correction coefficients.

3. Standard Viscometer Method

The standard Viscometer method is another calibration method that uses a standard Viscosity Cup (K-value cup) to verify the coated -4 Viscosity Cup. The standard Viscosity Cup has a known viscosity value, and the correction factor K can be obtained by comparing the measurement results of the coated -4 Viscosity Cup with the value of the standard Viscosity Cup.

4. Engra conditional degree method

The Engra conditional degree method is the third calibration method, which calculates the correction factor K using the ratio of the time required for the sample to flow out 200 mL of the Viscometer at a specific temperature to the time required for the distillation water to flow out the same volume at 20 ℃. This method has a narrower range and is gradually being replaced by the Miscellaneous method.

5. Summary

There are many ways to calibrate the -4 Viscosity Cup, and each method has its own applicable situation. Regardless of which method is used, the purpose of calibrate is to ensure the accuracy and Reliability of the measurement results. In Coating production and quality control, calibrating the -4 Viscosity Cup is an important step to ensure product mass, which can improve the controllability and stability of the Coating manufacturing process.

6. Reference standards

The calibration method introduced in this paper refers to the national standard GB/T 1723. In practical applications, the appropriate calibration method should be selected according to the characteristics and requirements of the Coating, and the calibrating steps should be carried out in strict accordance with the standard to ensure the accuracy and Reliability of the measurement.