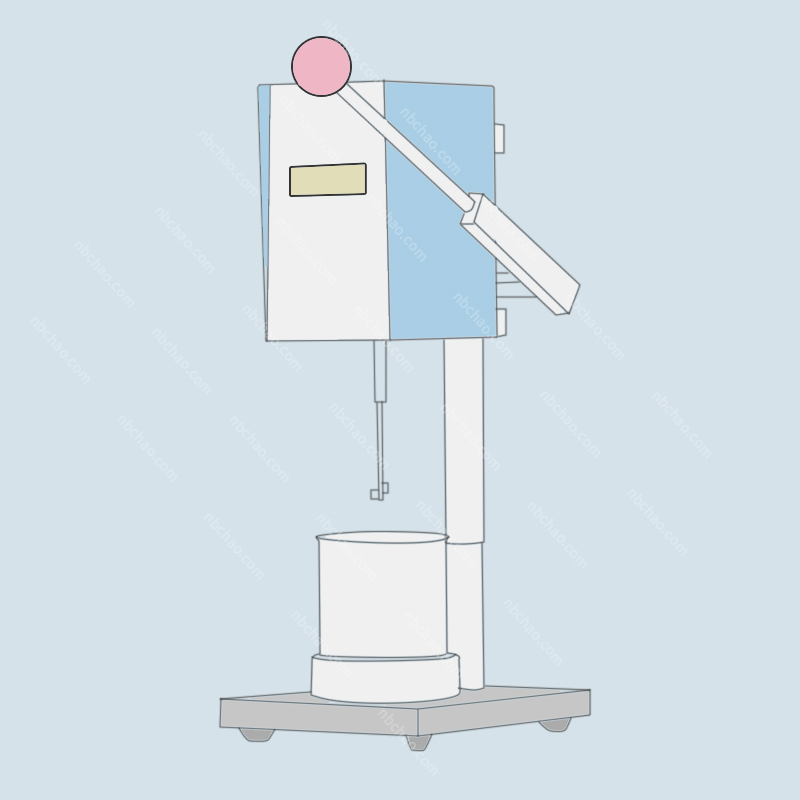

In modern industry, viscosity is a key parameter in the properties of liquid flow. Stormer Viscometer, also known as KU Viscometer, is an important test instrument and is widely used in Coating, Food, Daily Chemicals, Pharmaceuticals, Automotive, New materials, New Energy and other fields. This article will discuss the working principle of Stormer Viscometer, the application industry and the precautions.

Viscometer principle and characteristics

The Stormer Viscometer stands out for its ability to accurately measure viscosity consistency. It is mainly used to measure the viscosity consistency of coatings such as paints, which are expressed in KU values. Unlike traditional weighted Viscometers, the Stormer Viscometer uses advanced technology to directly read the KU, gm and cp values of the tested samples through the display screen. In addition, the instrument can also measure the temperature of the sample, and can preset the test start time and Measurement time, and display the measurement Linear dispersion map in real time, providing the operator with comprehensive data.

Multi-domain application

Stormer Viscometers play an important role in many different industries. Here are some of the main Applications:

1. Coating industry: In Coating production, accurate control of viscosity consistency is the key to ensuring coating mass. Stormer Viscometer can help manufacturers monitor the flowability of Coatings, thus ensuring the uniformity and stability of Coatings during the Spreader process.

2. Food industry: During Food processing, the consistency of certain liquid foods is critical to the taste and quality of the product. With Stormer Viscometer, food manufacturers can precisely control the flowability of their products to ensure their conformity during processing and Encasement.

3. Daily chemical industry: The consistency of cosmetics, shampoo, body wash and other daily chemical products also needs to be controlled to ensure the use experience and effect of the product. Stormer Viscometer provides an effective tool for the daily chemical industry to adjust the consistency parameters of products.

4. Pharmaceutical industry: In the pharmaceutical manufacturing process, the consistency of liquid medicine can affect the stability and release of drug efficacy. Stormer Viscometer helps pharmaceutical manufacturers monitor and adjust the consistency of liquid medicine to ensure drug mass and performance.

5. Automotive industry: Liquids such as automotive lubricants and chilled down fluids need to maintain proper viscosity consistency during engine operation to ensure normal engine operation. Stormer Viscometer can be used to evaluate the flowability of liquids at different temperatures.

6. New materials and new energy sources: In the field of R & D New materials and new energy sources, the measurement of viscosity consistency is of great significance for the performance and applicability of materials. Stormer Viscometer provides researchers with a tool for evaluating the flowability and properties of New materials.

Application environment and precautions

To ensure the accuracy and stability of the Stormer Viscometer, the following environment and operational details should be noted:

Viscometers should be placed on a table away from strong airflow, strong magnetic fields, strong electric fields and strong electromagnetic pulse interference.

The temperature in the laboratory should be maintained at 25 ℃ +/- 2 ℃, and the relative humidity should not exceed 75%.

The temperature of the test sample should be kept at 25 ℃ +/- 0.2 ℃.

Handle the instrument with care before and after use to avoid damage to precision measurement components.

Do not open the instrument shell by yourself, so as not to affect the accuracy of the instrument.

When the instrument is not in use, keep the lifting handle on a high limit device to avoid inflexibility in lifting. Remove the blades for cleaning after each test to keep the blades clean.

The blade is connected to the Sensors of the instrument. Do not pinch the blade by hand when swirling/spinning, so as not to damage the Sensors and cause measurement errors.

The product is guaranteed for one year, and improper use or man-made damage is not covered by the warranty.

The instrument should be checked regularly every year to ensure its normal performance, and it can also be sent to the Measurement Supervision Department for testing.

The Stormer Viscometer plays a key role in every Application as an important tool for viscosity consistency measurement. With reasonable operation and environment control, the instrument can provide reliable consistency data for production and research in various industries, thereby promoting product mass and innovation development.