In the modern industrial field, the quality and safety of products are crucial. In order to ensure the integrity of materials and components, non-destructive detection technology came into being. Among them, ultrasonic flaw Detectors are widely used in the engineering field as a powerful tool, which can quickly and accurately detect defects inside materials, thus ensuring the quality and safety of products.

How it works:

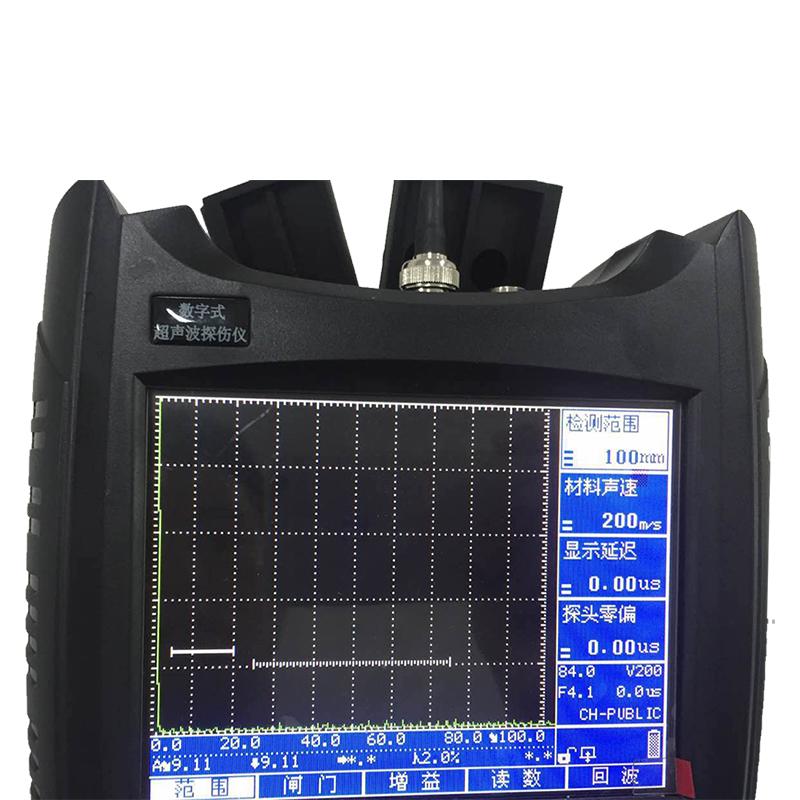

The principle of an ultrasonic flaw Detector is based on the propagation and reflection of sound waves. Specifically, it employs a pulse reflection technique that emits ultrasonic waves through the probe into the interior of the object being measured. Reflections occur when ultrasonic waves encounter a heterogeneous interface, such as a defect. The reflected signal is received by the probe and an echo is formed on the display screen. The height of the echo is related to the depth and size of the heterogeneous interface. The deeper the defect echo, the smaller the defect, and the lower the echo, and vice versa. This principle enables ultrasonic flaw Detectors to accurately locate and evaluate internal defects without destructive detection of materials.

Application:

Ultrasonic flaw Detectors are widely used in the industrial field. It can be used in the following industries and application fields:

Aerospace - Used to detect cracks and fatigue damage in aircraft parts and ensure the safe operation of aircraft.

Petrochemical - Detects corrosion and cracks in pipes, tanks and equipment to prevent leaks and accidents.

Manufacturing - Used to detect defects in welds, castings and forgings to ensure the quality of manufactured products.

Metalworking - Used to detect cracks and pores in metallic materials to ensure the performance of components.

Medical - used in medical imaging, such as ultrasound, for diagnosis and treatment.

Architecture - Detects defects in concrete structures and ensures the safety of buildings.

Advantages and Applicable Conditions:

Ultrasonic flaw Detectors have the following advantages:

Non-destructive testing: does not damage the material and can be tested during production or during product use.

High precision: It can detect small size defects and improve product quality control.

Multi-material applicability: Suitable for a variety of materials such as metals, composites and plastics.

Real-time detection: real-time display of detection results to improve work efficiency.

However, ultrasonic flaw Detectors also have applicable conditions, mainly including:

The material of the measured object is a sound-conducting material, such as metal.

The thickness of the measured object is not less than 4mm, and generally 6mm and above are recommended.

The appearance structure of the measured object should not be too complex or abnormal.

As an efficient and accurate non-destructive testing tool, ultrasonic flaw Detector provides important support to the industrial field. It helps enterprises to ensure product quality, improve production efficiency, and reduce safety risks. When choosing and using ultrasonic flaw Detector, it is crucial to understand its principle, application field and applicable conditions to fully realize its potential and ensure the quality and safety of products. Ultrasonic flaw Detector has become a right-hand man in the field of modern engineering, helping all walks of life to achieve greater success.