It is very simple to bend the metal plate coated with the paint film to measure and remove the film elasticity, so it is widely used in the mechanical test of the paint film. The easiest way to measure elasticity is to bend the paint film around metal rods of different diameters, and then observe whether there are cracks.

But when the paint film is bent around a metal rod, what we actually measure is not the elasticity of the paint film, but some properties of the wire, namely the tensile strength and tensile strength, the plasticity and adhesion of the paint film to the bottom surface Properties, etc. (related instruments: viscometer). Therefore, the method of bending the paint film around the rod to determine its mechanical properties should be called the bending test.

This method can give very good results in many cases, which can indicate the actual strength of the paint film and the painted object under various deformations.

Determination of Elasticity on HNNJIK Elasticity Scale

The standard method of bending test on the HNNJIK elastic Tester (0CT10086-39, test method 22) is widely used.

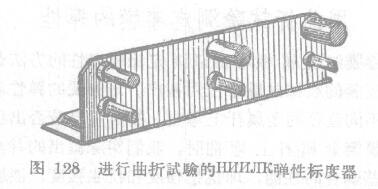

The HNNJIK elastic Tester is composed of a set of six steel rods with different thicknesses, and the steel rods are fixed on the board by the screw width and pads (Figure 128).

The diameters of the steel rods are as follows (mm): 20; 15; 10; 5; 3; 1; Fix the Tester firmly on the side of the test bench.

The test was carried out at a temperature of 18-20°C. (Related instrument: constant temperature and humidity Test Chamber) Remove the sample on a white iron plate with a thickness of 0.2~0.3 mm (length 100 mm, width 50~70 mm) according to the TOCT method or the method specified in the technical conditions. After the coating film is dry or after the time specified in the technical conditions, cut the white iron board into slats with a width of 20 mm and a length of 100 mm. Place a strip (paint film facing upwards). Crane a steel rod with a diameter of 20mm; bend it at an angle of 180°. The iron plate bends uniformly in 2~3 seconds. If after the paint film has been bent, no cracks can be seen with a magnifying glass, or the paint film does not fall off when you pass it with your fingers, then bend the other part of the slat around a steel rod with a diameter of 15 mm. Then bend the new part of the slat around a steel rod with a diameter of 10 mm and continue in this way until the cracks in the paint film can be seen in a magnifying glass four times, or the paint film falls off when the finger is passed over.

The test result may be expressed by the diameter of the last steel rod in the test in which the paint film remained intact.

The film flex test method described above provides a good approximation of the actual stretchability of those films which adhere well to the metal panel. For paint films with poor adhesion (nitro paint, etc.), the stretchability cannot be determined by this method. This method is also rarely used in comparative tests of highly elastic paint films (cooked oil, oil-based paint, etc.), because when the paint film is bent on a steel rod with a diameter of 1 mm, its maximum elongation is equal to 23.2% ( See below), and the paint film with extremely high elasticity has a degree of elongation much larger than this number. Therefore, it is impossible to measure the extensibility in fact. (Related instrument: bending Tester)

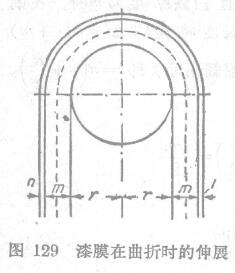

When the paint film is wound on the steel rods of different diameters of the HNNJIK elastic scale; when it is bent, the calculation of its relative extensibility is carried out as follows. If it is assumed that when the test plate is bent around the steel rod, the middle part of the plate surface maintains the original length, but the inner part (the part close to the steel rod) shrinks, and the outer part stretches, then when the steel rod radius When r is r and the thickness of white iron is m, the length of the outside of the plate surface on the half circumference of the steel rod section will be Z+△==π(r+m)

It can be seen that the greater the thickness of the paint film, the longer it will stretch when other conditions are equal. Now enumerate according to formulas (1) and (, 2), well under such conditions (when the paint film is bent on the steel rod of the HNNJIK elastic scale: m = 0..25 mm; paint film Thickness, n=0.02 mm (relevant instrument: Thickness Gauge); and assuming that the paint film does not appear cracks and does not peel off from the test panel (with good adhesion]), the relative elongation of the paint film calculated:

Lever diameter, mm……………2015l0531

Elongation of the inner surface of the paint film, %...1.231.642.444.757.7020.00

Elongation of the outer surface of the paint film, %...1.431.902.835.528.9323.20

When the paint film has weak adhesion and is slowly bent around the steel rod, the paint film will fall off from the metal surface, so that the elongation of the paint film is measured, that is, the measurement of its stretchability. becomes impossible. Sometimes in the case of bending too fast, the paint film has broken before it can fall off the test panel. In this case, it shows that the paint film has a large deformation speed.

If a very thin metal plate (such as a thin sheet with a thickness of 0-02 mm) is used as the bottom surface, the elongation of the paint film is relatively small when the metal plate is bent; it is calculated as 3.s5% according to the formula (1), and in In this case, the stretchability of the paint film can not be judged according to the degree of adhesion of the paint film to the bottom surface. However, most paint films can withstand such stretching (pulling the table) without cracks under the condition of bending once, and satisfactory results cannot be obtained by using thin-film test panels.

It is most correct to use a bend test carried out with the painted sheet subjected to repeated bending and straightening.

The test is continued until the paint film loses its elasticity due to "fatigue" of the specimen. The elasticity of the paint film can be judged by the number of times of bending.

Determination of flexural strength of paint film by multiple bending method

Put the paint film of glass or the paint film coated on metal sheet (10~20mm wide, 60~80mm long) between two dense drawing papers, and make the tested paint film protrude 20mm . Hold the two sheets between your fingers to hold the paint film between the two sheets in place. After that, fold the protruding part of the paint film back and forth (to both sides) so that it is in contact with the paper and observe where the paint film is folded. The deflection of the paint film shall continue until cracks form at the deflection.

The flexural strength of the paint film is expressed by the number of times the paint film can withstand reverse bending without cracking.

The test must be repeated several times to get the average value.

The test was carried out before artificial aging and after artificial aging.

The strength of the paint film subjected to multiple bending can be carried out on the reverse folding instrument, which has been widely used in the paper industry and leather industry.