The variety of coating methods is inevitable in different application fields and coating types. In this article, we will discuss in detail the different methods of coating, including hand coating, dip and spray coating, air spraying, and airless spraying. Each method has its own unique advantages and applicability, and it is critical to choose the right coating method according to specific needs and project requirements.

1. Hand painting

Hand painting methods include brushing, roll coating and scraping. Brushing is the process of applying paint evenly to the surface of the object to be coated with a brush through manual operation. The advantages of this method include paint saving, simple tools, convenient construction and strong adaptability. Brushing is suitable for various types of paints, but it is labor-intensive and less efficient. It is not suitable for fast-drying paints, and is prone to some problems, such as brush marks, sagging and uneven painting.

Roll coating is a manual coating method that rolls paint over the surface to be coated. It is suitable for large-area painting and is more efficient than brushing, but it requires more material and is usually used for the coating of latex paints.

Scratch coating is a method of applying paint by hand with a scraper to form a thick coating film. It is usually used for applications such as filling holes, leveling, plugging joints and smearing.

2. Dip coating and spray coating

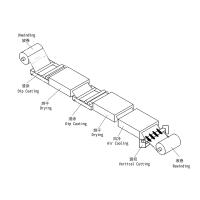

Dip coating is a method of forming a coating film on the surface of the coated object by completely immersing the coated object in the paint, then lifting it and dripping the excess paint back into the paint container. Manual dip coating is suitable for intermittent small batch production, while mechanical dip coating is suitable for continuous mass production lines. However, the dip coating method has some limitations, such as the inability to carry out color registration, the thickness of the coating film on the upper and lower parts of the coated object is uneven, the solvent volatilization is large, it is easy to pollute the environment, and the paint loss is large.

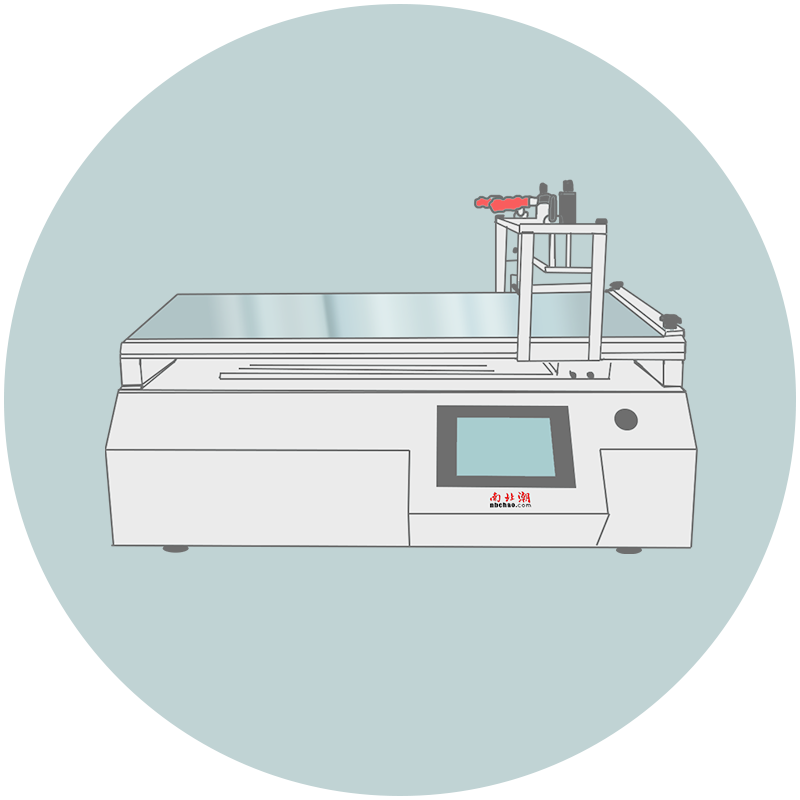

Spraying is a method of forming a uniform coating film by storing paint in high-level grooves and then drizzling it over the coated material through nozzles or slits. Excess paint flows back into the container and is recycled. This method is suitable for the coating of mass-produced flat and ribbon materials such as steel sheets and plywood.

3. Air spray

Air spraying is one of the widely used painting processes at present. It uses compressed air to form a negative pressure through the nozzle hole of the Spray Gun, so that the paint is sucked in, and then sprayed out to form a uniform paint mist, which covers the surface of the parts to be painted, and finally forms a uniform coating film. Air spraying can produce a uniform paint mist, making the sprayed coating delicate and smooth, and is suitable for more hidden spraying parts, such as gaps and concave and convex parts. In order to control the paint mist during the spraying process, spraying is usually carried out in a spray booth with exhaust and paint mist removal equipment. In addition, by preheating the paint to 60-70 degrees Celsius, thermal spraying can be achieved, thereby reducing the use of solvents.

4. No air spray

Airless spraying is a method of pressurizing the paint to 5~ 35MPa through a high-pressure pump, and then spraying it from a special nozzle hole. When the paint is sprayed, due to the rapid drop in the impact air and pressure, the solvent evaporates rapidly, the volume expands suddenly, disperses and atomizes, and finally adheres to the surface of the object to form a uniform coating film. This method is suitable for high viscosity coatings.

In general, the choice of coating method depends on the type of coating, coating needs and production scale. Different methods have different advantages and applicability, so these factors need to be fully considered when choosing a coating method to ensure the best coating effect and production efficiency. Whichever method is selected, it needs to be carried out in a safe environment and strictly abide by the standards and procedures of the coating operation to ensure the quality and safety of the coating process.