Coatings play an important role in various applications, and the hardness of a film is a key parameter to measure its performance. Scratch hardness testing is a commonly used method for evaluating the hardness of a film to ensure that it meets the requirements of a specific application. This article will introduce the method and importance of scratch hardness testing.

1. Pencil hardness method

Pencil hardness method is a commonly used scratch hardness test method, which can be used to test film hardness on rigid substrates in situ. This method is usually divided into manual operation and instrument test.

Manual operation: When manual operation, use a pencil with known hardness to test the hardness of the film. The Tester puts the pencil at a 45 ° angle with the sample and pushes it forward with a force that just does not break the lead lead. The result is expressed as a hardness that just does not scratch.

Instrument test: During instrument test, advanced drawing pencils that meet the standards are usually used. Instrument models such as QHQ pencil method scratch Hardness Tester. Different countries use different pencil hardness grades. My country's national standard GB 6739-86 stipulates a 13-grade hardness grade from 6H to 6B, 6H is the hardest and 6B is the softest.

2. Scribing method

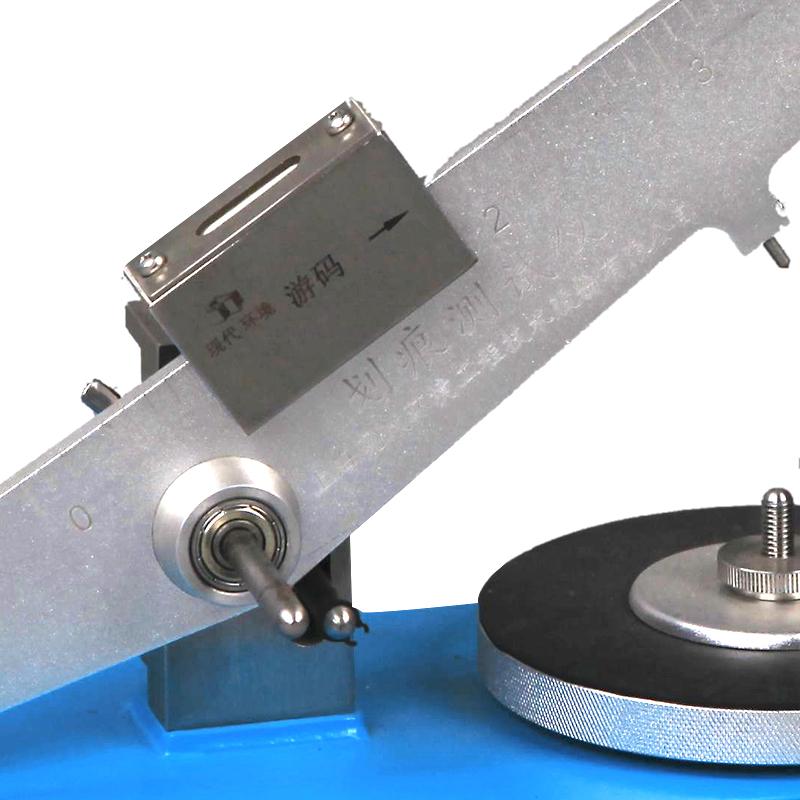

A scribing method is a method of using an instrument to scratch film through the tip of the instrument to test its hardness. The advantage of scribing is that it provides a more accurate hardness assessment and can use automatic or manual instruments.

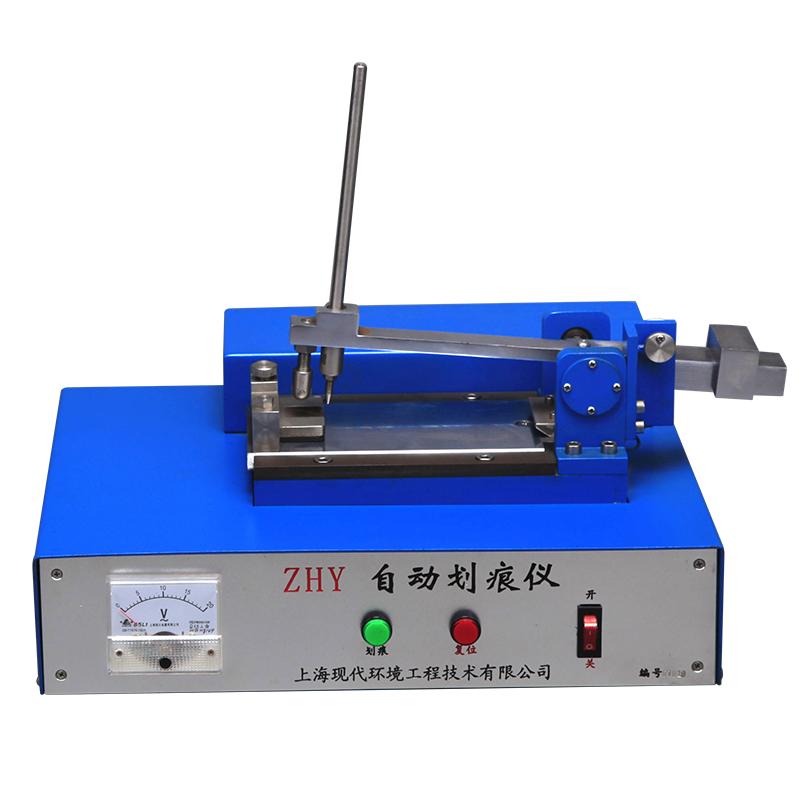

Automatic type instrument: Automatic type scribing needle measuring instrument can directly display the results through conductivity, and is usually used in large-scale production and quality control of coatings.

Manual type instrument: Manual type scribing needle measuring instrument requires the operator to manually push the needle tip of the instrument, which is suitable for hardness testing in laboratory and small-scale production.

3. Importance of scratch hardness

Scratch hardness testing plays an important role in the Coatings industry:

Quality control: Through scratch hardness testing, manufacturers can ensure that the hardness of Coatings meets product standards and customer requirements, thus providing high-quality painting products.

Performance evaluation: film hardness reflects the combination of performance such as modulus, tensile strength and adhesion. Hardness testing helps evaluate film abrasion resistance and scratch performance.

Film Selection: Scratch hardness testing can help manufacturers choose the type and formulation of Coatings suitable for specific applications.

Film durability: Knowing the hardness of a film can help predict its durability and longevity in actual use.

In conclusion, scratch hardness testing is an important method for evaluating film hardness and is essential to ensure the performance and mass of films in various applications. Manufacturers can choose suitable test methods according to different application needs to ensure that their films meet specific hardness requirements. This helps to increase product mass, reduce painting problems, and enhance film performance.