Polyester resin, as a widely used polymer material, its properties and quality are crucial. Melting point is a key indicator to evaluate the purity and composition of polyester resin, and the determination method and accuracy naturally become important research contents. In this article, we will deeply explore the determination method, principle and practical application significance of the melting point of polyester resin.

The importance of melting point determination

Melting point refers to the temperature at which a substance changes from a solid state to a liquid state. It not only reflects the purity of the substance, but also can provide a reference for the composition of the polymer. For polyester resins, melting point is an important indicator to evaluate their performance and quality. An accurate melting point determination can help researchers understand the structure and purity of the resin, providing a basis for further applications and research.

Determination principle

When we observe the change of the state of the polyester resin sample at different temperatures, we can infer its corresponding melting point and melting range from these changes. By observing the phase change of a small sample under a microscope, we can know its corresponding melting point and melting range.

Measurement method and equipment

To determine the melting point, it is first necessary to prepare the corresponding equipment and materials. This includes:

A balance accurate to 0.001 g for weighing samples.

Beakers and mortars for sample handling and grinding.

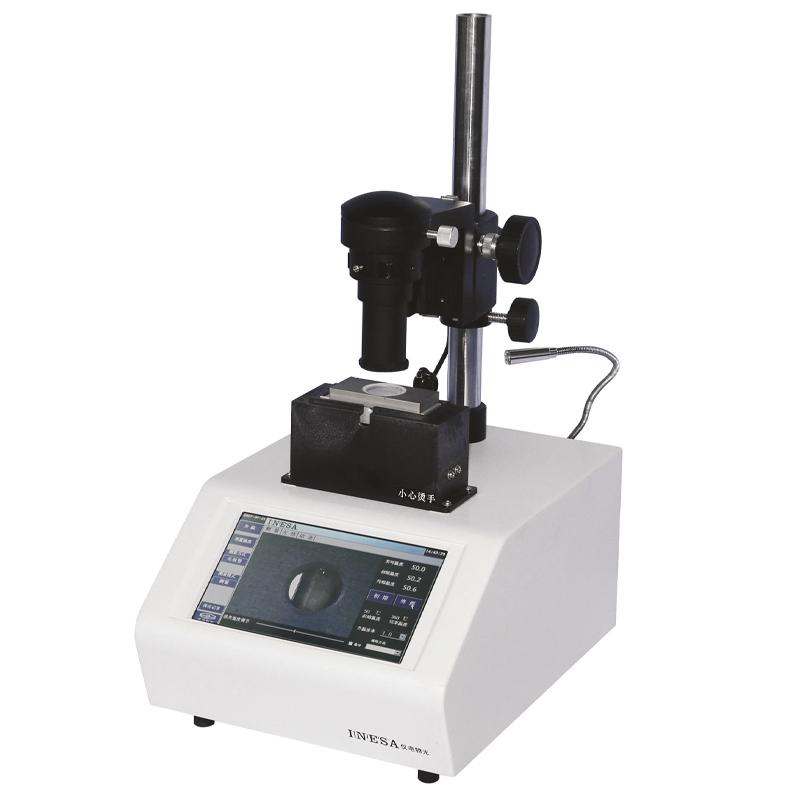

A measuring instrument, which is a specialized device, includes a binocular zoom stereo microscope, a Heating Plate and its adjustable temperature regulator, a temperature measurement display, and a sample heating and insulation platform.

The specific measurement process involves: taking a small amount of sample (less than 0.1mg), grinding it evenly and diluting it on a glass sheet, then covering it with another glass sheet and placing it in an appropriate position on a heated and insulated platform. Then, the sample is observed using a microscope, and the test temperature is heated and displayed at the same time. When the temperature is close to the expected melting point, adjust the heating rate until the sample is observed to transition from a solid state to a liquid state or a glass state to a highly elastic state. At this time, the temperature is the melting point.

Results representation and reference standards

The result of the melting point determination should be the arithmetic mean of three measurements and accurate to one decimal place. In addition, to ensure the accuracy and consistency of the determination, we should refer to relevant standards, such as CNS 1508-82 "Determination of Melting Point of Chemical Reagents".

summarize

Melting point determination of polyester resins is not only a key step in evaluating their purity and properties, but also of great significance for further research and applications. Accurate melting point determination can provide researchers with valuable information to help them better understand and optimize the properties and applications of polyester resins. And with the advancement of science and technology, we have reason to expect the emergence of more advanced and accurate determination methods and equipment to further promote the development of polyester resin research and application.