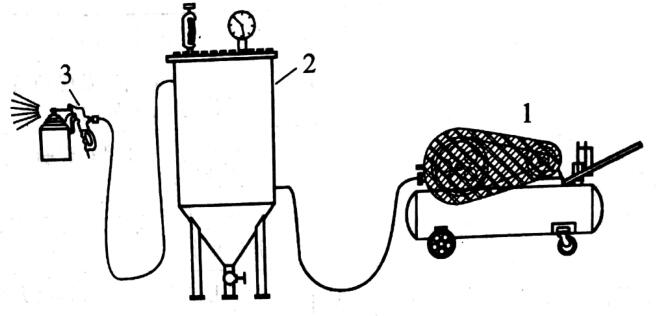

The air pressure spraying device is composed of Air Compressor, Spray Gun, oil-water separator, hose, paint storage tank, spraying cabinet (room) and so on. As shown in Figure 5.

Schematic diagram of spraying and coating equipment configuration

(1) Small Air Compressor (air pump) (2) Oil-water separator (3) Paint Spray Gun

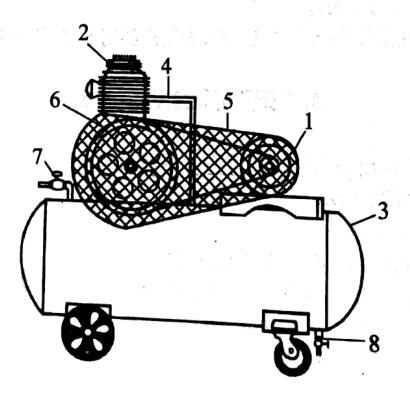

Air Compressors are referred to as Air Compressors, also known as air pumps. For low-pressure Air Compressors. General spraying construction only needs 0.2-06 MPa (2-6 kgf/cm2). According to the air supply per minute, Air Compressors are divided into small (10m2/min), medium (10~30m2/min) and large (30m2/min or more), which can be selected according to the coating batch and the number of Spray Guns configured to select. Distinguish from the shape and structure of the Air Compressor: there are fixed and mobile. Figure 6 is a mobile Air Compressor with wheels under the fuselage. Usually the Air Compressor is equipped with a pressure gauge and a safety valve. It should be checked for reliability before use. Adjust a predetermined deflation pressure (such as 0.6 MPa (6 kgf/cm2)), then start the Air Compressor, close the output valve of compressed air, and observe when the pointer of the pressure gauge rises to the predetermined discharge pressure, The safety valve automatically deflates and decompresses. After inspection, it can be formally connected with the oil-water separator for use. If the Air Compressor does not have a safety valve and a pressure gauge, the safety valve and pressure gauge can be arranged on the oil-water separator or the air storage tank. Before formal use, the test of the safety valve should also be carried out to ensure safe production.

Mobile small Air Compressor

(1) Electric motor (2) Pump head (3) Air storage tank (4) Intake pipe (5) Wheel belt cover (6) Oil hole (7) Exhaust valve (8) Oil and water discharge valve

The Air Compressor should be checked regularly during use, the rotating parts should be lubricated frequently, and all parts should be kept clean. The running time should not be too long, and it should not be overloaded or empty. Before each start of the Air Compressor, drain the oil and water in the machine, close the exhaust valve (as shown in (7) in Figure 6), and then open the exhaust valve for spraying after reaching the required spraying pressure. Before shutting down, the exhaust valve should be closed first, and then the power of the Air Compressor should be turned off to avoid sucking back.