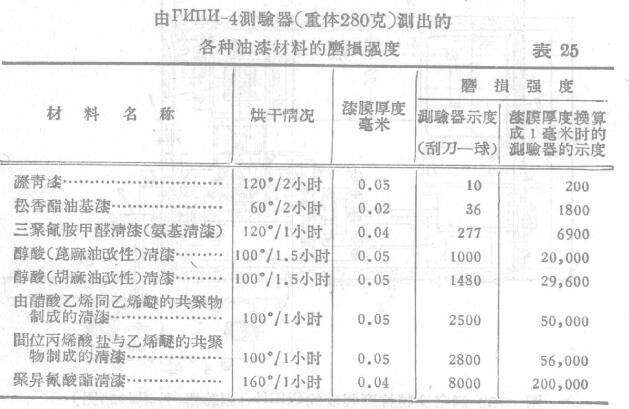

Yakubovich, Rubinstein, and Vorogushin 6S proposed a set of methods and instruments for measuring the abrasion resistance of paint films. The appearance and sketch of this Tester are shown in Figure 152. It is composed of a motor 1 (0.2/0.1 ampere; 127/220 volts) and a rotating shaft (by friction transmission, there is an eccentric wheel with a link on the rotating shaft) 2) Constituted. A clip for fixing the scraper is installed on the end of the connecting rod. (Related instruments: Abrasion Tester)

The connecting rod reciprocates on the metal plate coated with the film to be tested. The test plate is fixed on a special stage 7. The stage moves along the strip 3, which makes it possible to test on different parts of the test plate (1-2 mm apart). An upright pin is installed on the central and tight head of the connecting rod for fixing the removable weight, and the eccentric wheel is connected with the counter 5 which records the number of reciprocating movements of the connecting rod. In order to stop the motor automatically after the test is connected, an electrical appliance 6 connected to the scraper clip and the test plate must be used. Motor stalling occurs when the line is cut when the scraper comes into contact with a metal plate exposed due to damage to the coating film. Transformer 8 is used to reduce the voltage on the scraper (to prevent the scraper from burning and forging).

According to the technical conditions, place the metal plate with the paint material removed between the clips of the stage. A scraper is fixed in the middle of the clip, and a weight can be added to the scraper if necessary. Land the ]1mm rod with a scraper on the board, and start the motor to make the connecting rod run.

At the end of the test, that is, when the paint film is damaged, the electric appliance automatically cuts off the motor. The test shall be repeated 10 times on each part of the test panel. The indication read from the counter can be used as the abrasion strength of the coating film (the arithmetic mean value of ten determinations). Depending on the type of paint material, various scrapers and different weights can be used.

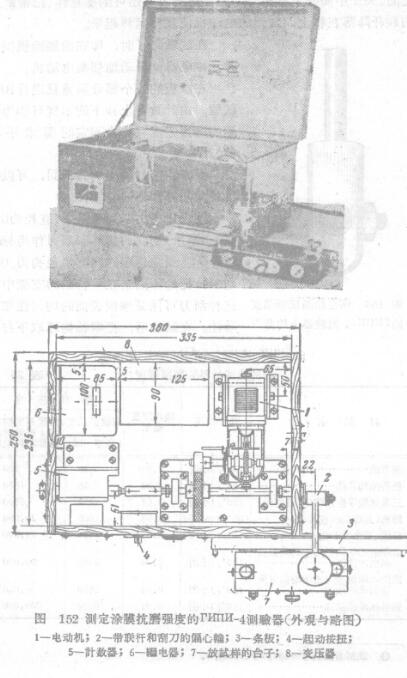

In the past, a fishing ring scraper made of steel wire (0.2-0.3 mm in diameter) was proposed as a standard-scraper 0; the radius of curvature of the wire fishing ring was about 0.5 mm; the shackle was fixed in a special bracket. This scraper can in turn guarantee the uniformity and standardization of the rubbing surface. After the test, the wire shackle is removed and a new wire shackle is inserted in its place. An overview of such a scraper is shown in Figure 153. (Related instrument: applicator)

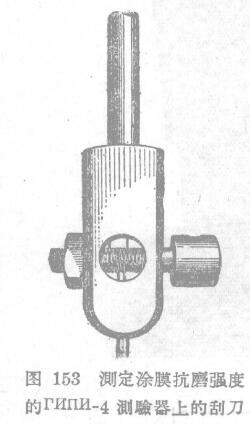

Table 25 lists the results obtained by measuring the abrasion strength of various paint materials on the TNNN-4 Tester. For the convenience of comparison, the display of the Tester is converted into a numerical value corresponding to a thickness of 1 mm of the paint film. (Related Instruments: Thickness Gauge)