introduction

In the coatings industry, understanding the scratch resistance of a paint film is critical. The GB/T 92798-2008 standard provides a scratch test method to determine the ability of a paint film to resist scratches. This article will provide an in-depth look at the principles, operation, results presentation, precautions and importance of this method in the coatings industry.

The scratch test evaluates the scratch resistance of a paint film by measuring the minimum load or work required to scratch the paint film being tested. The basis of this method is to determine the minimum load required for the instrument's scribing needle to penetrate the paint film, usually expressed as the hardness of the paint film. In addition, it can also be judged under a certain load whether the paint film has been penetrated by the scribe needle, and the performance of the paint film can be expressed in terms of pass or fail.

Materials and Instruments

In order to conduct a scratch test, the following materials and equipment are required:

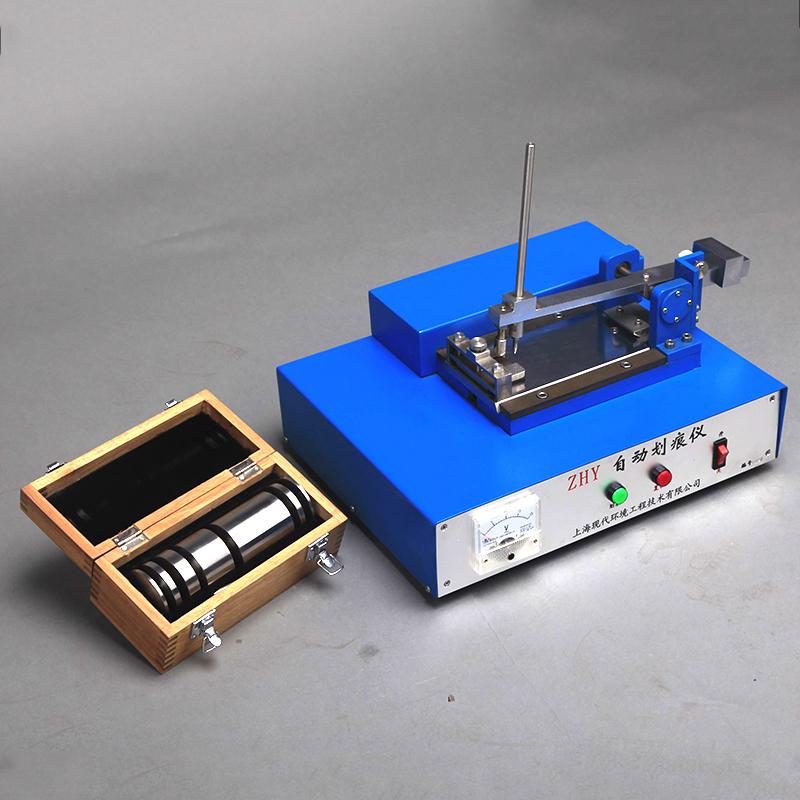

Scratch Meter: Used to apply load and perform scratch testing.

Tinplate plates, thin steel plates, duralumin plates: used as substrates on which the specimens will be fixed for scratch testing.

Operational points

When conducting a scratch test, you need to pay attention to the following operating points:

Fix the sample on the movable workbench of the instrument, then turn on the instrument and the workbench begins to move at a constant speed.

The scribing needle will move on the sample board, and according to the scratch situation, gradually add load to the scribing needle until the paint film is just scratched.

Result expression

The result of the scratch test is expressed as the minimum load required when the paint film is scratched. This value is usually used to express the hardness of the paint film. The larger this value is, the harder it is to scratch the paint film and its higher scratch resistance.

Notes and Importance

When performing a scratch test, special attention needs to be paid to the following matters:

The selected substrate should be flat to ensure the accuracy of the test.

Use conductive instruments and equipment, so the back of the sample being tested should not be coated with any insulating material to ensure the consistency of conductivity.

When painting, ensure that the brush marks are parallel to the long sides of the test panel to maintain the consistency and accuracy of the test.

Application Importance

Scratch testing has a wide range of applications in the coatings industry. Understanding a paint film's ability to resist scratches helps manufacturers evaluate the quality and performance of their coating products. This is essential to ensure the durability of coatings under different environmental conditions, especially in applications that require higher abrasion resistance, such as automotive coatings and furniture coatings.

In addition, scratch testing can be used to research and develop new coating formulations to improve the scratch resistance of paint films. By understanding the scratch performance of different coating materials under different loads, manufacturers can tailor formulations to meet the requirements of specific applications.

in conclusion

GB/T 92798 Paint and varnish scratch test is an important coating performance testing method used to evaluate the scratch resistance of paint films. By determining the minimum load required to break the film, critical information about the hardness of the paint film can be obtained. The application of this test method in the coatings industry helps manufacturers ensure the quality and performance of their products and provides basic data for product improvements. Therefore, scratch testing plays an important role and is widely used in the coating industry.