With the continuous advancement of technology, lithium-ion batteries, as important energy storage devices, have been widely used in mobile devices, electric vehicles, renewable energy storage and other fields. In the core structure of lithium-ion batteries, the separator is one of the crucial components. Since lithium batteries involve high energy density and chemical reactions when working, the separator plays a key role in isolation and safety protection. In recent years, with the rapid development of the electric vehicle market, the demand for the safety of lithium batteries has become more urgent and important.

Lithium-ion battery separators are mainly composed of microporous films and have high physical isolation performance and ionic conductivity. This microporous structure allows lithium ions to pass through, but at the same time prevents direct contact between the positive and negative electrodes, thereby avoiding dangers such as short circuits. During the charging and discharging process, the performance of the separator directly affects the stability and safety of the battery. To ensure the safety of electric vehicles and other battery applications, scientists and engineers have been working to improve and evaluate the performance of lithium battery separators.

Critical performance testing of diaphragms

When evaluating the performance of the separator, a number of key indicators are covered, including but not limited to: Thickness uniformity test, Air permeability test, Mechanical performance test, Thermal dimensional stability test, Electrolyte adsorption and retention ability test and conductivity, etc.

1. Thickness uniformity test

The thickness uniformity of the separator is critical to the overall performance of the battery. Thickness uniformity testing over a wide range of thicknesses using thin film measurement equipment. In this test, the focus is on the thickness differences of the separator in different directions (TD and MD) to ensure that it has stable thickness characteristics.

2. Air permeability test

The breathability of the separator is a factor that needs to be considered for the chemical reactions inside the battery. By testing the gas permeability of the separator, its impact on gas exchange during battery cycling can be evaluated to ensure adequate ion channels.

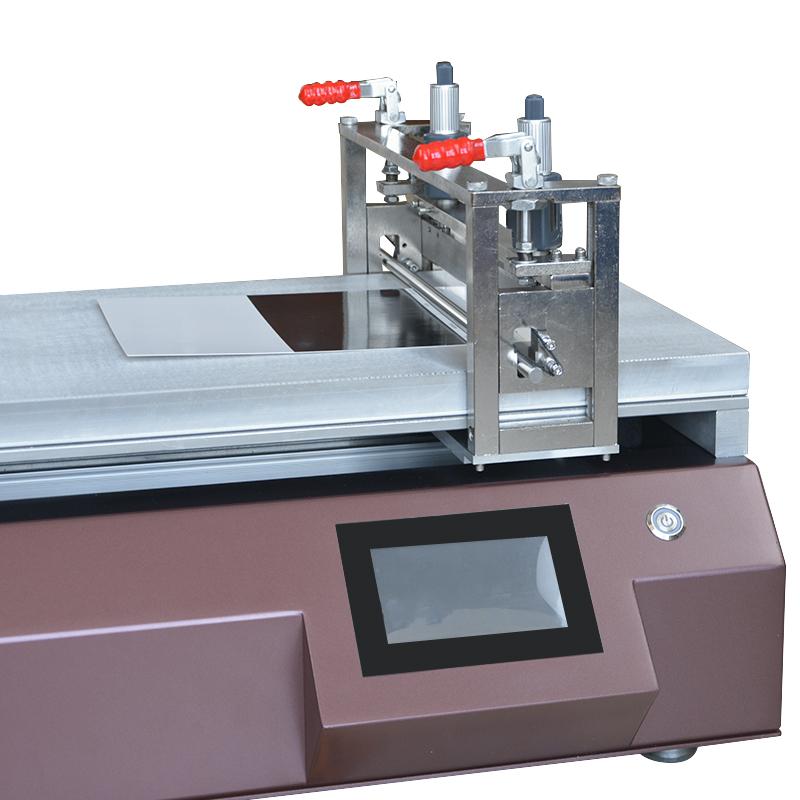

3. Mechanical performance test

Mechanical properties include tensile strength, elongation at break, puncture strength and peel strength. These tests evaluate the diaphragm's stability and durability under stress, as well as its safety under impact or external forces.

4. Thermal dimensional stability test

In high temperature environments, the stability of the diaphragm is crucial. The thermal shrinkage rate is tested to evaluate the dimensional change rate of the separator under high temperature conditions to ensure its stability and safety at different temperatures.

5. Electrolyte adsorption and retention capacity test

The ability of the separator to adsorb and retain electrolyte affects the flow and stability of the electrolyte inside the battery. Good electrolyte handling helps reduce the battery's internal impedance and improves battery performance.

6. Ion conductivity test

The ionic conductivity of the separator is directly related to the charge and discharge efficiency of the battery. Testing the ion conductivity properties of the separator helps evaluate the efficiency of ion transport within the battery.

Multiple performance tests of separators are key to ensuring the safety and performance stability of lithium-ion batteries. Through these tests, the stability, reliability and safety of the separator in practical applications can be comprehensively evaluated, providing solid technical support and guarantee for the safety of electric vehicles and other battery applications. In the future, with the continuous development of technology, the continuous improvement of the performance of lithium-ion battery separators will be one of the important tasks in the fields of scientific research and engineering.