The paper coating process is complex and requires the use of a variety of equipment and instruments to achieve the desired properties of the final product. Understanding the equipment, instrumentation, and experimental methods used in these processes is critical to ensuring product quality and consistency. The following is an overview of the key equipment, instruments and experimental methods involved in the paper coating process.

Equipment and Instruments

| Electronic Balance | High speed disperser |

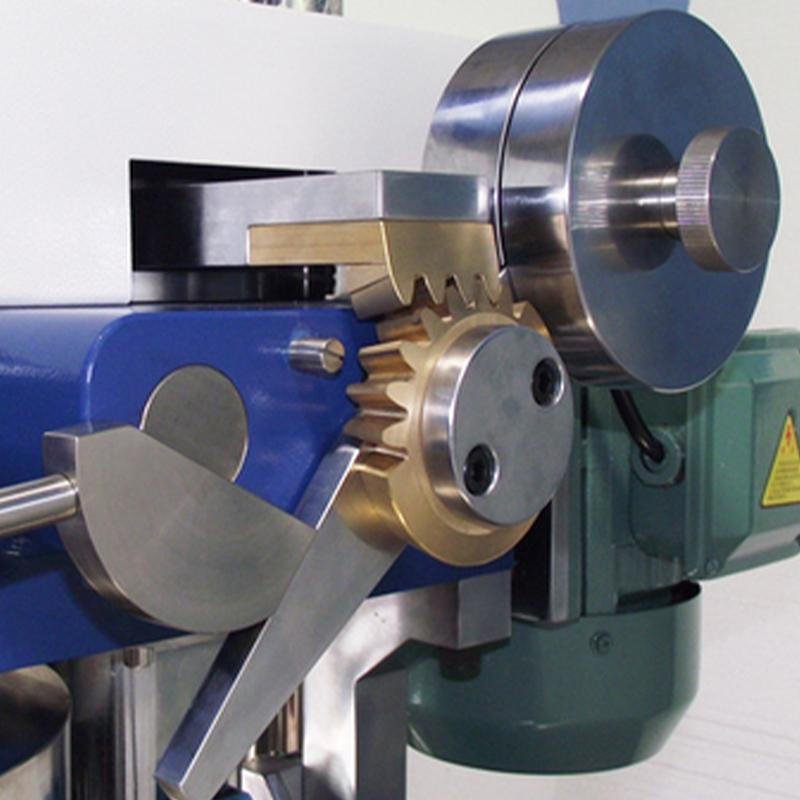

| fiber standard separator | Laboratory coater |

| Laboratory multi-purpose calender | Viscometer |

| Electric constant temperature Forced Air Drying Oven | scanner |

| Tank Freeness Tester | Gloss meter |

| percussIon Meter | Computer measurement and control smoothness meter |

| Laboratory rapid copying machine | Printing performance Tester |

experimental method:

1. Beating

Beating is a process in which the pulp board is torn into small pieces of a specific size and then soaked in water for a certain period of time to loosen and stir. First, the pulp raw material board is torn into small pieces of specified size, and then soaked in water for a period of time to soften the fibers. Next, agitation and agitation are performed by specialized equipment, such as a Valli Freeness Tester or other slurry handling device, to thoroughly disperse the fibers and achieve the desired slurry texture and properties.

2. Ease

Deflaking refers to soaking pre-treated pulp boards in specific equipment for chemical or physical treatment to open the fiber bundles and dissociate the fibers. This process can use equipment such as fiber standard dissociators to subject the fibers to shearing, stretching and tearing through the flow of water or mechanical rotation, so that they are separated into smaller fibers and improve the quality and uniformity of the pulp. sex.

3. Mixing pulp

Pulp mixing is to mix and stir different types of pulp raw materials according to predetermined proportions and formulas to prepare pulp that meets the requirements. The key to this step is to ensure that the various pulp ingredients are mixed correctly in the designed proportions and stirred evenly to achieve the desired paper characteristics and quality.

4. Copy the film

Papermaking is a papermaking process that uses prepared pulp material on a papermaking machine according to a predetermined plan. In this process, chemical additives are added to the pulp according to the design plan, and then the pulp is made into sheets of paper through rollers or other devices on the paper machine.

5. Surface sizing

Surface sizing is a process in which the base paper is treated with a specific process and then glue is applied to the surface of the paper under constant temperature and humidity. This process involves gelatinizing substances such as cationic starch and mixing them with other sizing agents in proportion, and then calendering and hand-coating the paper after being treated at constant temperature and humidity.

6. Coating preparation

Paint formulation involves the dispersion and mixing of materials such as pigments and binders. First, the pigment is weighed and the dispersant is added for dispersion treatment, then the binder is added, including the auxiliary binder and the main binder latex, and finally other additives such as hydration resistance agents, lubricants and substances needed to adjust the pH are added , maintain the rotation speed to mix the paint evenly.

7. Paint viscosity test

Use a Rotational Viscometer to test the viscosity of the paint. By setting the rotation speed, observe and record the viscosity of the paint under specific conditions to ensure that it meets production requirements.

8. Paper coating experiment

Place the base paper on the coating machine as required, coat it through the machine and monitor the quantity and uniformity of the coating to meet the specific requirements of the product.

9. Paper calendering experiment

The coated paper is calendered under constant temperature and humidity conditions to make the paper surface flatter and smoother and improve the overall quality of the product.

10. Paper performance test

The coated paper is subjected to a variety of performance tests, including tests on gloss, smoothness, printed surface strength, thickness, opacity, whiteness, tensile strength and cohesion.

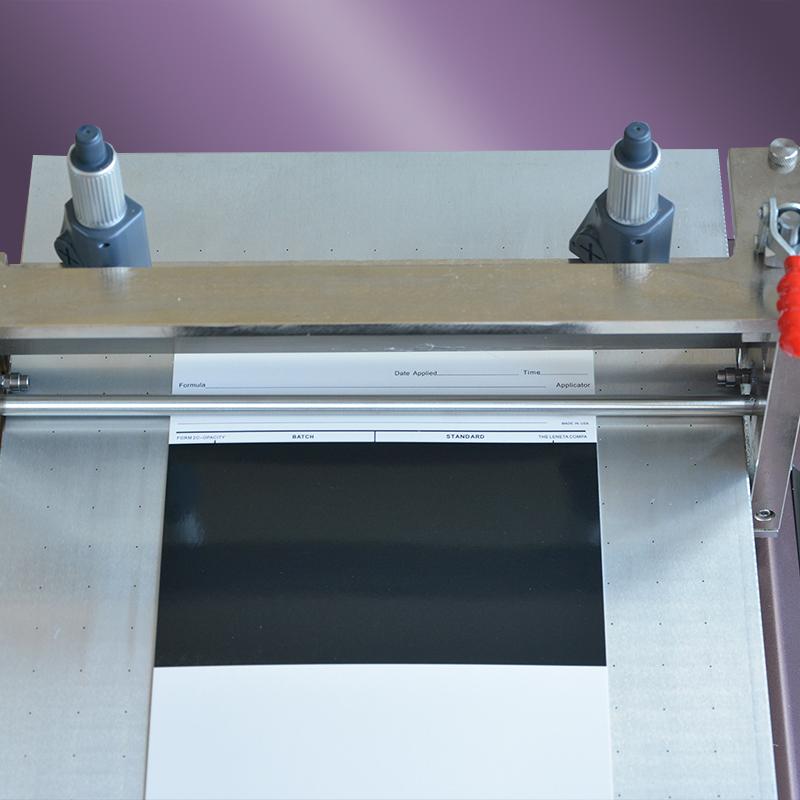

11. Determination of coating coverage

Quantitative analysis of coating coverage of coated paper by burning method. This process uses specific experimental steps and equipment to process the coated paper, and uses equipment such as scanners to observe and quantitatively analyze the coverage of the coating.