The wash resistance Tester is an instrument specially designed to evaluate the wash resistance of coatings. It is mainly used in the fields of coating production and research. By simulating the washing process, it can measure the durability of the coating in different environments and provide key data to ensure the quality of the coating. The significance of the coating wash resistance test is to comprehensively evaluate the durability and performance of the coating by simulating the scrubbing conditions in the actual use environment. This test not only helps in quality control and ensures consistency between coating batches, but also provides important data on the adaptability of coatings in different usage environments, providing manufacturers with an effective quality assurance method.

principle

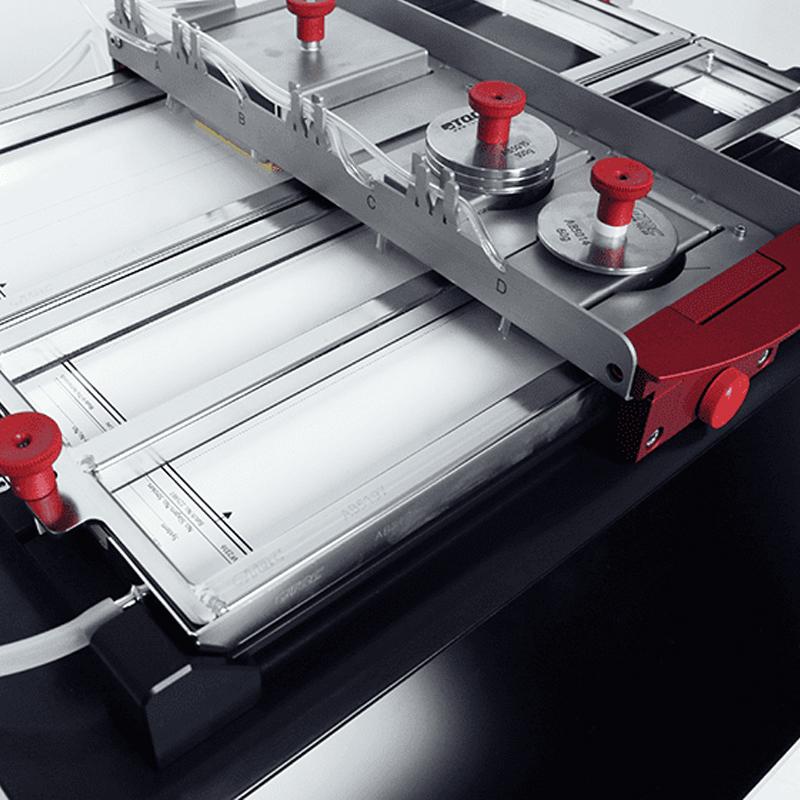

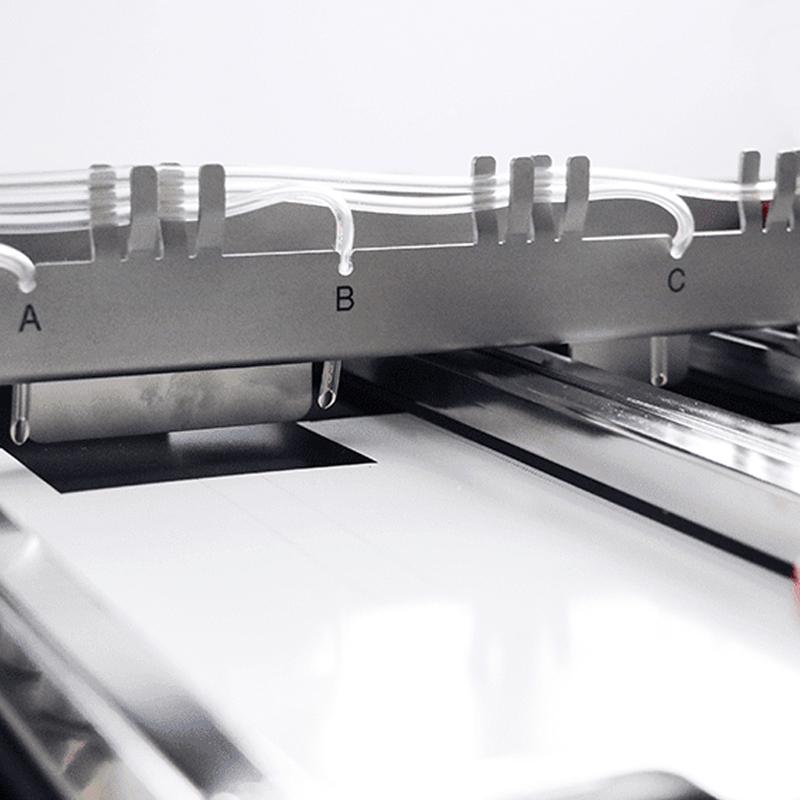

The principle of the instrument is based on the reciprocating motion of the brush on the coating surface to simulate brushing conditions that may be encountered in actual use. Its design takes into account key parameters such as the brush's own weight and frequency of movement to ensure test accuracy and reliability. During the test, the energy lost by the brush is detected by the electronic circuit and precisely converted by the processor, and finally presented as visual wash resistance performance data. This design and principle enable the instrument to accurately simulate the brushing process in actual use environments, providing reliable technical support for the durability evaluation of coatings.

Testing purposes

Evaluate the wash resistance of the coating: Ensure that the coating is not easy to peel or wear during use and improve the durability of the coating. Provides real-time quality monitoring of the production process to ensure consistency between paint batches. Provide data support to help developers improve coating formulations to meet the requirements of different usage environments.

Steps

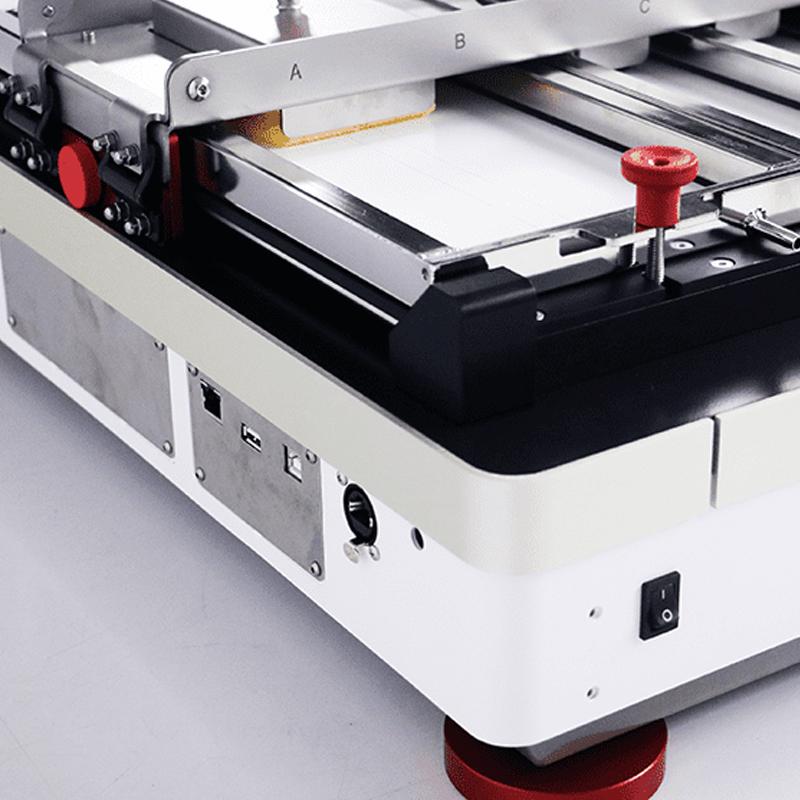

First, give the brush a pre-treatment. Soak it in water at 20°C for 30 minutes until the depth reaches 12mm, and then squeeze out the water. Next, soak in 0.5% soap for 10 minutes. Then comes the stage of preparing the test board. Put the test panel into the work plate and secure it firmly with the test panel presser feet at both ends. Next comes the brush replacement operation. When the machine is stopped, the brush can be pulled out by pulling the handle and replaced with a new brush easily. Donât forget to ensure that the brushâs weight of 450 grams is always squeezed onto the test plate.

Now, adjust the parameters. Plug in the power and use the preset button to set the number of washes you want. Press the reset button and the machine will enter the waiting state. Do some liquid-adding operations. Pour 0.5% soap solution into the liquid storage cylinder, then open the mouth cock and drip soap solution onto the test plate. Don't stop, keep the test plate wet. Press the start switch to start the test. The brush starts moving back and forth and the counter starts counting on its own. During the test, don't forget to keep dripping soap solution to keep the test plate moist.

Check for wear and tear. Check the 10 centimeters in the middle of the test panel to see if there are any signs of wear or bottoming. If necessary, use the stop switch to stop the machine midway. Finally, reset and continue testing. If the test piece is not exposed but the counter has reached the predetermined value, press the reset button to restart counting and continue the test. Once you complete this series of steps, you will have important information about the paint's resistance to scrubbing, helping to ensure the quality and durability of your paint product.