Sponge coated with graphene is a technology that uses graphene materials to improve the properties of sponges. Sponges are usually porous materials with high specific surface area, and are often used for applications such as absorbing liquids, filtering, and isolation. Coating graphene can give sponges some special properties, such as enhanced adsorption capacity, improved conductivity, and improved mechanical properties, thus expanding their applications in various fields. Main applications include:

Oil-water separation: Sponge coated with graphene can increase the affinity of the sponge for oil and improve the oil absorption capacity. This makes it the preferred material for oil-water separation and oil pollution treatment. Graphene-coated sponges can quickly absorb oil molecules and expel water molecules, achieving efficient oil-water separation.

Wastewater treatment: Graphene-coated sponges have good adsorption capacity for organic pollutants and can be used for pollutant removal during wastewater treatment. Its efficient adsorption properties make it a strong candidate in the field of water treatment.

Electronics: Coating the sponge with graphene enhances the conductivity of the sponge, making it suitable for use in electronic devices such as sensors, flexible electronic components, etc. This application can promote the flexibility and performance of electronic devices.

Waterproof coating: The graphene-coated sponge surface can form a coating with waterproof performance, improving the water resistance of the material. This is widely used in construction, aerospace and other fields.

Energy storage: Due to the conductive properties of graphene, coating on sponges can be used to prepare high-performance energy storage devices such as supercapacitors and batteries, improving energy storage efficiency.

Environmental monitoring: Using the electrical conductivity of graphene coated on sponges, highly sensitive sensors can be prepared for monitoring various chemicals, gases, etc. in the environment.

Ocean cleaning: Graphene-coated sponges have a strong adsorption capacity for oil pollution in the ocean and can be used to clean up oil pollution in the ocean.

Preparation method

Chemical reduction method: use a reducing agent to reduce graphene oxide to graphene, then disperse the graphene in a solution, soak the sponge in this solution, and adhere the graphene to the surface of the sponge.

Mechanical mixing method: The graphene is mechanically mixed with the sponge, and the graphene is evenly distributed on the surface of the sponge by physical mechanics.

Chemical Vapor Deposition: Using chemical vapor deposition technology, a thin layer of graphene is deposited on the surface of a sponge

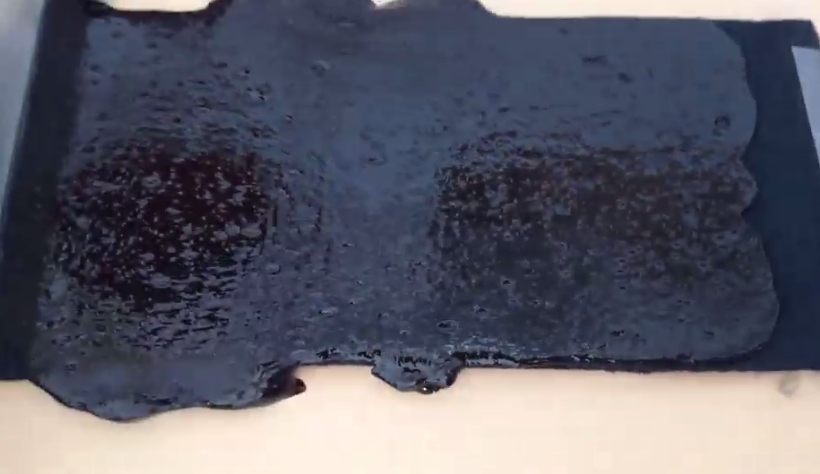

So is the scraping method suitable? Nanbei Tide's technology has done experiments. Since the viscosity of the user's sample is very large, there are particles, and there are pits on the surface of the coating, which can be successfully scraped, but the effect is relatively rough. Technical analysis, if the viscosity of the sample is smaller and there is no such obvious granularity, then you can try scraping with a scraper coater.

Precautions

During the preparation process, it is necessary to ensure that the graphene can be evenly dispersed on the sponge to give full play to its properties.

The temperature, time and other conditions during the preparation process need to be strictly controlled to ensure that graphene can be effectively adhered to the surface of the sponge.

Graphene is a relatively expensive material, and cost factors need to be taken into account during the preparation process, especially in large-scale applications.

During the preparation process, environmentally friendly methods should be adopted as much as possible to minimize the impact on the environment.

Consider the specific application field of coated graphene sponge, select the appropriate graphene type and preparation method to meet the specific needs.