As a representative of textiles, the appearance gloss of fabric is directly related to the beauty and quality of the product. In order to ensure accurate measurement of fabric gloss, a detailed set of testing standards has been developed. This standard applies to fabrics of various textures and colors, but does not include high-pile fabrics.

1. Testing principle

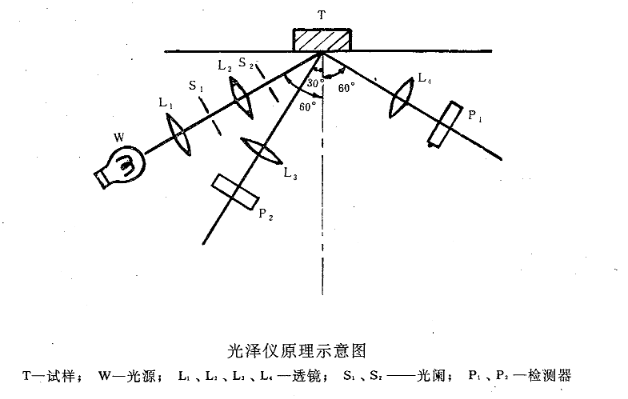

The test uses parallel light from light source A at an angle of 60° to illuminate the sample. The light intensity of the object is obtained by measuring the regular reflected light and diffuse reflected light at 60° and -30° angles. By comparing the light intensity of the two, the glossiness of the fabric is calculated.

2. Explanation of terms

Gloss: The degree to which a surface reflects incident light.

Gloss: A specific measure of gloss.

Specular reflection: The phenomenon in which the angle of reflection is equal to the angle of incidence.

Diffuse reflection: The phenomenon that the reflection angle is not equal to the incident angle.

Contrast gloss: The ratio of regular reflected light intensity to diffuse reflected light intensity.

3. Required equipment

The equipment required for testing includes a fabric gloss meter and a schematic diagram of the gloss meter:

4. Environmental conditions

The environmental conditions of the test were set according to the standard atmosphere, that is, the temperature is 20±2°C and the relative humidity is 65%±2%.

5. Sample preparation

Three representative specimens were cut from each sample, with a size of 100 mm à 100 mm. The specimens should be smooth and free of yarn flaws or other obvious defects.

6. Test steps

6.1 Instrument calibration

6.1.1 Place the instrument on a platform away from direct sunlight.

6.1.2 Before testing, perform a 30-minute warm-up period.

6.1.3 Place the dark tube on the measuring port of the instrument and adjust the zero point of the instrument.

6.1.4 Replace the standard plate and adjust the instrument so that the reading matches the value of the "standard plate".

6.1.5 Repeat steps 6.1.3 and 6.1.4 until the requirements are met.

6.2 Test methods

6.2.1 Make the test surface of the sample face outward, stretch it flatly on the dark slip, and then place it on the measuring port of the instrument.

6.2.2 Rotate the sample stage for one revolution and record the maximum value of Gs and its corresponding GR value.

7. Data calculation

Fabric gloss is calculated using the following formula:

Gc=Gs/(Gs-Gr)

in:

Gc: fabric gloss.

Gs: Fabric regular reflected light gloss, %.

Gr: The difference between the gloss of regular reflected light and the gloss of diffuse reflected light of fabric, %.

Calculate the average value of the three samples, and keep the result to one decimal place according to the numerical rounding method.

8. Test report

a. Test date;

b. Sample name;

c. Test conditions;

d. Average value of fabric contrast gloss;

e. Any details that deviate from this standard and abnormalities during testing must be noted;

f. Test method standards.

Through this set of standard testing procedures, we can accurately evaluate the gloss of fabrics, providing a scientific basis for product production and quality control. This standard helps ensure that fabrics maintain a consistent high level of quality in the marketplace.