introduction

In today's era of rapid technological development, advances in materials science have had a profound impact on all walks of life. Silicon material, as an important semiconductor material, is widely used in electronics, optoelectronics, energy and other fields. As the application scope of silicon materials continues to expand, the demand for surface coatings is also growing. In order to improve the quality, efficiency and consistency of coating films, automatic silicon material coating machines have emerged. This article will conduct an in-depth study of the principles, technical characteristics, application fields and future development trends of silicon material automatic coating machines to provide readers with a comprehensive understanding.

Technical principles of automatic coating machine for silicon materials

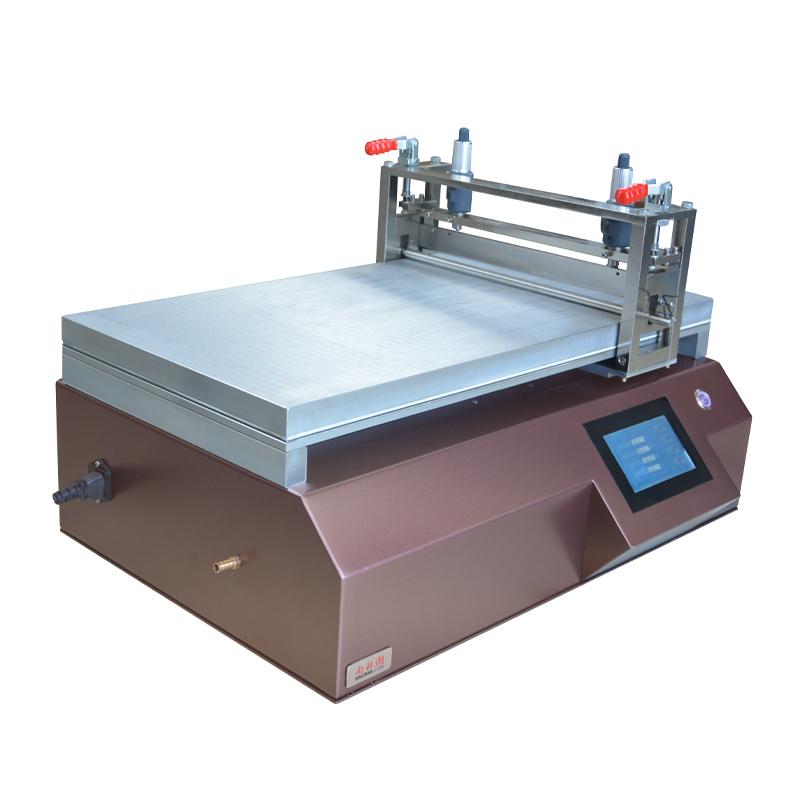

The automatic coating machine for silicon materials is an advanced piece of equipment. Its operating principle is based on advanced coating technology and automated control systems. During the coating process, the surface of the silicon material needs to be cleaned first to ensure the adhesion and uniformity of the coating. Next, the coater uses a precision spray or brush system to evenly apply the coating to the surface of the silicone material. An automatic control system monitors the thickness, uniformity and quality of the coating to ensure that each silicone material meets specific technical requirements.

During the operation of the silicon material automatic coating machine, advanced optical detection systems can also be used to monitor the quality of the coating in real time. This real-time feedback mechanism makes the coating preparation process more precise and controllable. At the same time, automatic coating machines for silicone materials are usually equipped with highly flexible control systems that can be adjusted according to different coating requirements to ensure that they can adapt to diverse application needs.

The automatic coating machine for silicon materials has a high degree of automation and can achieve large-scale, high-efficiency production. Compared with manual coating, automatic coating machines can not only increase production speed, but also reduce the impact of human factors on coating quality. The advanced control system enables the silicon material automatic coating machine to achieve precise control of coating thickness, uniformity and quality. This is particularly important for some applications that require extremely high coating quality, such as optoelectronic device manufacturing. Silicone material automatic coating machines usually have the ability to adapt to a variety of coating methods and coating materials. This versatility allows the film coating machine to meet the needs of different industries and application fields, improving the flexibility of the equipment. As society pays more attention to sustainable development, silicon material automatic coating machines pay more and more attention to energy saving and environmental protection in the design and manufacturing process. The use of advanced coating technology and green coating materials reduces resource waste and environmental pollution during the production process.

Application fields of silicon material automatic coating machine

In semiconductor manufacturing and integrated circuit production, silicon material automatic coating machines are widely used to protect and enhance the performance of electronic devices. By forming a thin film on the surface of a silicon chip, the stability and reliability of electronic components can be improved. Silicon material is the main component of solar cells, and automatic coating machines are used to coat photosensitive materials on the surface of silicon wafers to improve the conversion efficiency of solar cells. In the manufacturing of optical devices, silicon material automatic coating machines are used to coat anti-reflective films, optical filter films, etc. to improve the transparency and performance of optical devices. In automobile manufacturing, silicon material automatic coating machines are used to apply anti-corrosion, anti-scratch and other functional coatings to the car body to improve the durability and appearance quality of the car. In device manufacturing, silicon material automatic coating machines are used to apply antibacterial, antioxidant and other special coatings to the surface of the device to ensure the safety and durability of the device.

With the development of artificial intelligence and big data technology, automatic coating machines for silicon materials will become more intelligent. The intelligent control system can make adaptive adjustments based on real-time data to improve production efficiency and coating quality. The continuous advancement of nanotechnology will be more widely used in automatic coating machines for silicon materials. Nano-coatings can give silicon materials stronger functionality, such as antibacterial and self-cleaning properties. In the future, automatic coating machines for silicone materials will be more inclined to use environmentally friendly and degradable green coating materials to reduce negative impacts on the environment. Manufacturers will pay more attention to independent innovation and promote the continuous improvement of the technical level of silicon material automatic coating machines. Innovate in coating technology, mechanical structure, etc. to meet changing market needs.

Conclusion

As an important technology in materials science and manufacturing, the silicon material automatic coating machine not only improves the quality and production efficiency of the coating, but also promotes the widespread application of silicon materials in various fields. With the continuous advancement of science and technology, silicon material automatic coating machines will usher in a broader space for development, providing strong support for innovation and progress in various industries.