Based on the analysis of the principle of the magnetoresistance method coating Thickness Gauge, combined with the calibration experience in recent years, this paper briefly explains the influence of the substrate material on the detection results of the magnetoresistance method coating Thickness Gauge in the measurement and detection.

0 Preface

As manufacturing, processing, chemical and other testing fields have higher and higher requirements for material protection, the technical level of portable coating Thickness Gauges is also developing rapidly, which can quickly, non-destructively and precisely measure coatings and coatings. Accurate measurement of thickness. Due to its strict requirements on the substrate material and coating material, coating Thickness Gauges of various principles have appeared on the market, common eddy current, magnetoresistive and ultrasonic coating Thickness Gauges. Based on the analysis of the principle of the magnetoresistive coating Thickness Gauge and the experience of calibration in recent years, this paper briefly explains the influence of the substrate material on the detection results of the magnetoresistive coating Thickness Gauge in the measurement and detection.

1 Principle of magnetoresistive coating Thickness Gauge

As manufacturing, processing, chemical and other testing fields have higher and higher requirements for material protection, the technical level of portable coating Thickness Gauges is also developing rapidly, which can quickly, non-destructively and precisely measure coatings and coatings. Accurate measurement of thickness. Due to its strict requirements on the substrate material and coating material, coating Thickness Gauges of various principles have appeared on the market, common eddy current, magnetoresistive and ultrasonic coating Thickness Gauges. Based on the analysis of the principle of the magnetoresistive coating Thickness Gauge and the calibration experience in recent years, this paper briefly explains the influence of the substrate material on the detection results of the magnetoresistive coating Thickness Gauge in the measurement and detection.

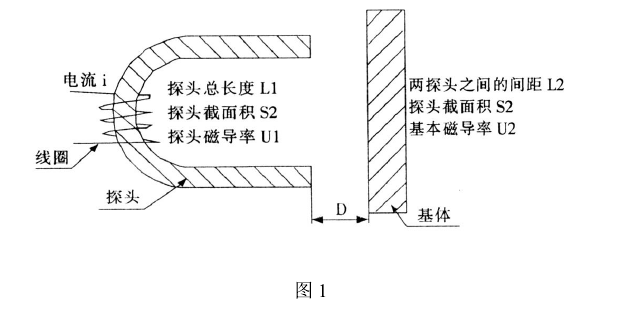

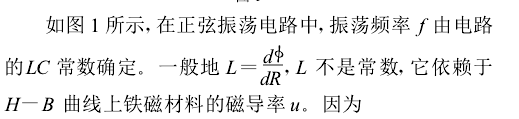

The magnetoresistance method coating Thickness Gauge adopts the principle of magnetic induction to measure, and the principle is mainly to use the difference of magnetoresistance between different materials. Use the probe to measure the magnetoresistance corresponding to the thickness of the coating to indicate its thickness. The thicker the coating, the greater the reluctance and the smaller the flux.

2 The influence of different substrate materials on the test results

It can be known from the above detection principle and method that when detecting the thickness of the coating, it has actually assumed that the magnetic resistance of the probe and the magnetic resistance of the substrate are known quantities, and then the functional relationship between the coating thickness and the frequency of the oscillating circuit is calculated, and saved in the microcontroller. During detection, the coating thickness is calculated according to the obtained functional relationship.

However, during the daily calibration of magnetoresistance coating Thickness Gauges, I found that many magnetoresistance coating Thickness Gauges are tested on different substrates, and their accuracy varies greatly. When using the substrate specified by the manufacturer, the result is relatively accurate; when using other ferromagnetic substrates, even if the calibration procedure is followed by the manufacturer, the measurement result is not accurate. It can be seen from formula (5) that the functional relationship between thickness and frequency is not linear. The calibration method of many manufacturers is single-point calibration or two-point calibration. This calibration method is often used to correct the coefficients of the correction function when the known constants remain unchanged. In the case of known constant changes, it is difficult to correct the function coefficients correctly.

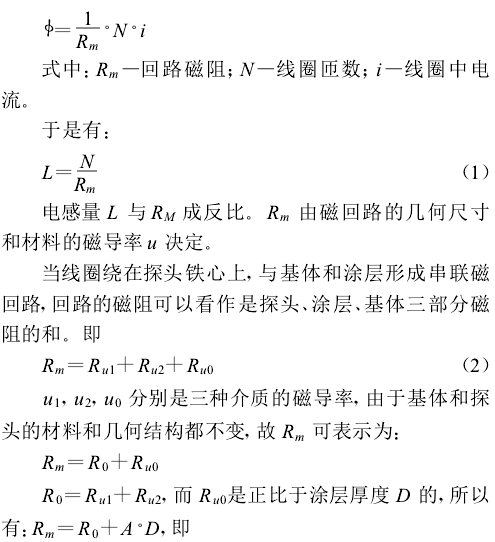

The change of the known constant is mainly due to the difference of the substrate material. At present, common ferromagnetic materials include cast iron, silicon steel, nickel-zinc ferrite, nickel-iron alloy, manganese-zinc ferrite, permalloy and so on. The relative permeability of these materials is shown in Table 1.

Obviously, the coating thickness measured by different ferromagnetic materials as the substrate must be different. If a magnetoresistive coating Thickness Gauge designed to measure cast iron substrates is used during detection, and nickel-iron alloy is used as the substrate during detection, then the detection results are likely to deviate from the true value.

3 Conclusion

In this paper, through the analysis of the principle of the magnetoresistive coating Thickness Gauge, combined with the practical experience in the daily measurement and calibration work, the influence of the substrate material on the detection results is demonstrated. It is hoped that the metrology department and the production and testing department of the enterprise will pay attention to the influence of the substrate material during the daily inspection and calibration or procurement process, and choose the appropriate model and required substrate material, so that the actual inspection will be more convenient and the test results will be more accurate. .