introduction

Hot sol film coating machine is a key equipment widely used in packaging, printing, medical and electronics industries. It melts hot melt and evenly coats it on the surface of different materials to achieve functions such as bonding, encapsulation or printing. However, during use, hot sol film coating machines often encounter some failures due to various reasons. This article will delve into the technical principles of hot sol film coating machines and provide solutions to common faults, aiming to help users better understand and maintain this critical equipment.

1. Working principle of hot sol film coating machine

The working principle of the hot sol film coating machine is based on hot melt adhesive technology and mainly includes the following steps:

Heating system: The hot sol film coating machine first heats the solid hot sol to its melting point through the built-in heating system, turning it into a viscous liquid state.

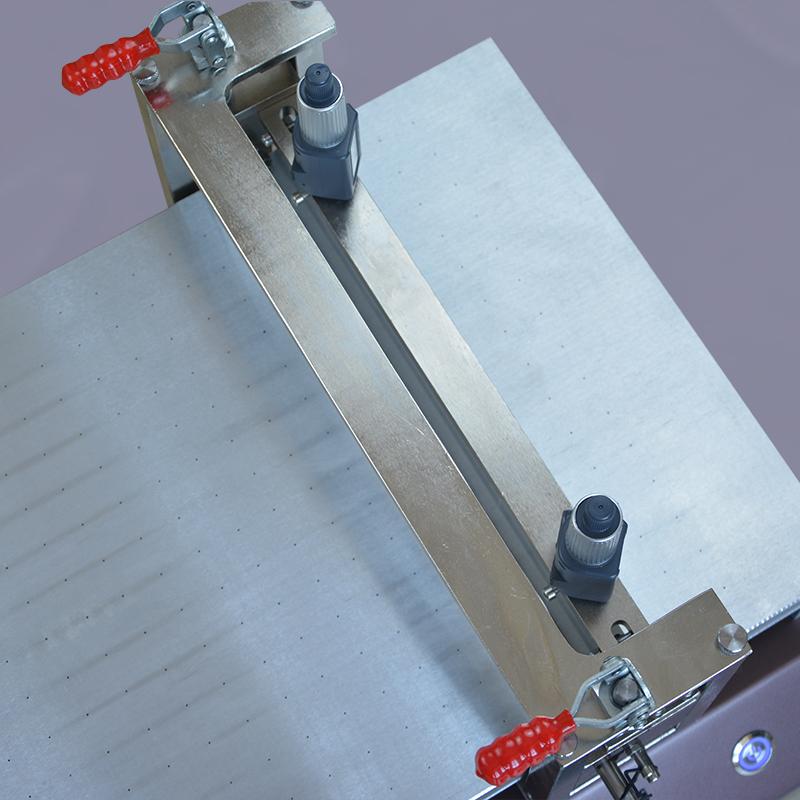

Coating system: The coating system uses a series of rollers or nozzles to evenly coat the hot sol on the surface of the material to be treated, ensuring the uniformity and stability of the coating layer.

Cooling and solidification: After coating is completed, the material passes through the cooling system to quickly solidify the hot sol to ensure the bonding or encapsulation effect.

2. Common faults and solutions

The coating layer is uneven or blistered:

Possible Causes:

The roller is unbalanced;

The coating nozzle is clogged;

The coating temperature is unstable.

solution:

Check roller balance and make adjustments;

Clean the coating nozzle;

Adjust the coating temperature to a stable state.

Unstable coating speed:

Possible Causes:

The coating roller speed is inconsistent;

The coating system pressure is unstable;

The viscosity of coating materials changes greatly.

solution:

Adjust the roller speed;

Check and adjust coating system pressure;

Choose the appropriate coating material and control its viscosity.

The device is too noisy:

Possible Causes:

Equipment parts are damaged;

The roller is unbalanced;

The coater base is unstable.

solution:

Check all parts of the equipment and replace damaged parts;

Adjust or replace rollers;

Make sure the machine base is firm and adjust the base.

Coating system clogged:

Possible Causes:

The hot melt solidifies in the nozzle or pipe;

Impurities enter the coating system.

solution:

Clean nozzles and pipes regularly;

Install filters to prevent impurities from entering the system.

Coating temperature is not up to standard:

Possible Causes:

Heating system failure;

Temperature controller failed.

solution:

Check and repair the heating system to ensure normal operation;

Replace or repair temperature controller.

in conclusion

Hot sol film coating machines play an important role in modern industry, and their normal operation is crucial to production efficiency and product quality. By having an in-depth understanding of its working principles and common troubleshooting solutions, operators can better maintain and manage equipment to ensure its long-term, efficient and stable operation, thereby providing more reliable production solutions for various industries.