Overview

As a small and precise equipment, laboratory hot melt adhesive machine is widely used in laboratory research, sample preparation and other fields. Compared with production hot melt glue machines, laboratory hot melt glue machines have significant differences in scale, accuracy, application scenarios, etc. This article will deeply analyze the technical principles and characteristics of laboratory hot melt glue machines, and compare them with production models to fully understand the advantages and disadvantages of laboratory hot melt glue machines.

1. Basic principles

1.1 Overview of hot melt adhesive technology

Hot melt adhesive technology is a process that uses high-temperature molten colloid for bonding. The laboratory hot melt glue machine heats the solid glue particles to a molten state, and then applies the molten glue to the materials to be bonded through a nozzle or roller coating, ultimately forming a strong adhesive layer.

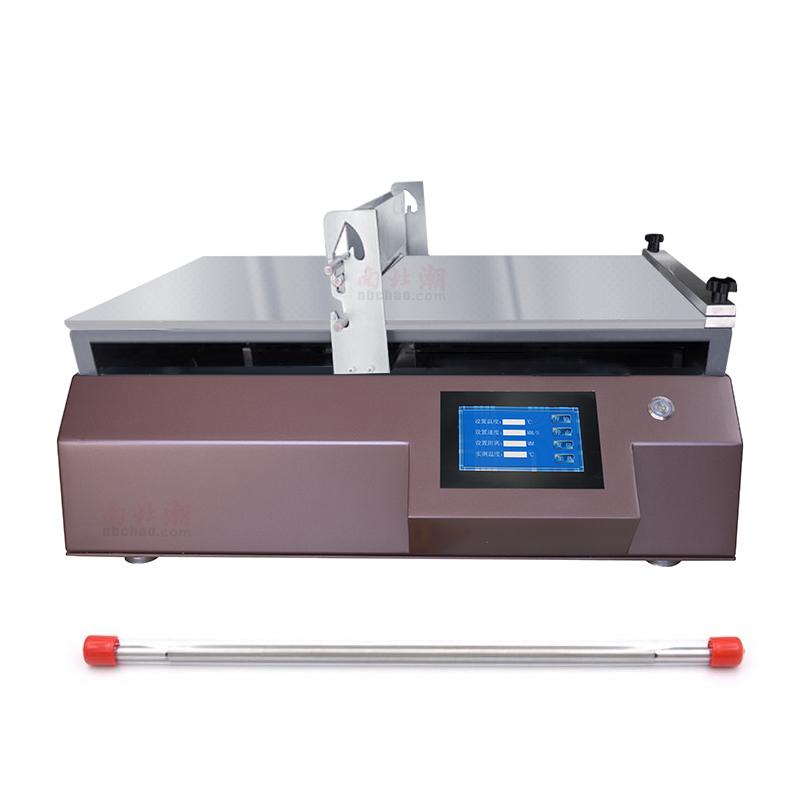

1.2 Composition of laboratory hot melt adhesive machine

Laboratory hot melt adhesive machines usually consist of heating system, coating system, control system, etc. The heating system is responsible for heating the rubber particles to the melting temperature, the coating system controls the coating method of the glue, and the control system is used to adjust parameters such as temperature and speed to ensure the stability of the glue.

1.3 Workflow

The workflow of the laboratory hot melt glue machine includes three main steps: heating of rubber particles, coating of glue liquid, and solidification of glue liquid. During the heating process, the glue particles are heated to a molten state; during the coating process, the molten glue is evenly coated on the target material through the coating system; during the solidification process, the glue is quickly heated through cooling or other methods. Cure to complete bonding.

2. Technical features

2.1 Miniaturized design

The laboratory hot melt glue machine is smaller and lighter than the production model, suitable for the small working space of the laboratory, and is easy to carry and move.

2.2 High-precision coating

Since laboratory hot melt glue machines are usually used for research and sample preparation, their coating systems are designed to be more precise, enabling precise control of the amount of glue applied to ensure the accuracy of experimental results.

2.3 Versatility

Laboratory hot melt glue machines are usually designed as multi-functional equipment that can meet different experimental needs, including glue of different materials, different coating methods, etc.

2.4 Low energy consumption

Since the scale of the laboratory is relatively small, the design of the laboratory hot melt adhesive machine pays more attention to energy efficiency optimization and reduces energy consumption.

2.5 Simple operation interface

In order to meet the operational needs of experimenters, laboratory hot melt adhesive machines usually have simple and intuitive operation interfaces, which lowers the threshold for use.

3. Comparison with production-type hot melt adhesive machines

3.1 Differences in scale

Production hot melt gluers usually have larger production capabilities and are suitable for large-scale production, while laboratory hot melt gluers focus on small-scale experiments and sample preparation.

3.2 Accuracy requirements

Laboratory hot melt glue machines pay more attention to the accuracy and stability of coating to meet the needs of scientific research experiments, while production hot melt glue machines may pay more attention to efficient production and have relatively low accuracy requirements.

3.3 Applicable fields

Laboratory hot melt glue machines are mainly used in laboratory research, sample preparation and other fields, while production hot melt glue machines are widely used in large-scale production fields such as packaging, electronics, and automobiles.

3.4 Technical complexity

Laboratory hot melt glue machines are usually designed to be relatively simple and convenient for experimenters to use, while production hot melt glue machines may involve more advanced control technologies to cope with complex production environments.

4. Application areas

4.1 Scientific research experiments

Laboratory hot melt glue machines are widely used in the field of scientific research for sample preparation, laboratory small batch production, etc.

4.2 Materials research

For the research of new materials, the laboratory hot melt adhesive machine can realize qualitative and quantitative research on material properties by adjusting coating parameters.

4.3 Electronic device preparation

Laboratory hot melt glue machines also play an important role in the preparation of electronic devices and are used in processes such as bonding and packaging to ensure the stability of the devices.

Conclusion

As an important tool for laboratory research and sample preparation, laboratory hot melt adhesive machines have obvious advantages in small size, high precision, and multi-function. By comparing with production hot melt adhesive machines, we have a deeper understanding of the unique value of laboratory hot melt adhesive machines in the field of scientific research. In the future, with the continuous advancement of science and technology, the design of laboratory hot melt adhesive machines is expected to be further optimized to meet more experimental needs and provide stronger support for scientific research and the development of new materials.