introduction

In today's era of rapid technological development, laboratory thin film coating technology plays a vital role in materials science, optoelectronics, energy storage and other fields. Thin film coating technology is a key process to form a uniform, dense and high-quality film on the surface of a substrate. As the core equipment for realizing this technology, the laboratory Film Applicator's performance and selection have an important impact on film quality and preparation efficiency. This article will delve into the technical characteristics, application fields and selection methods of laboratory thin film coating machines.

1. Technical characteristics

1. Coating method

The coating methods of laboratory thin Film Applicators mainly include spin coating, spray coating, roller coating, ion beam sputtering, chemical vapor deposition, etc. Spin coating is suitable for solution-based materials, while ion beam sputtering is commonly used for solid thin-film materials. The choice of coating method needs to be comprehensively considered based on the properties of the specific material and the purpose of the experiment.

2. Scope of coating materials

Different laboratory Film Applicators have different coating material ranges. Some machines are suitable for organic materials, while others are suitable for inorganic materials such as metals and oxides. When selecting, it is necessary to clarify the research direction of the laboratory and the type of film material used.

3. Coating speed and uniformity

Coating speed and uniformity are important indicators for evaluating the performance of laboratory Film Applicators. Higher coating speed can improve experimental efficiency, while good uniformity ensures film quality. Therefore, it is necessary to pay attention to the coating speed range and uniformity parameters of the machine when selecting.

4. Control system

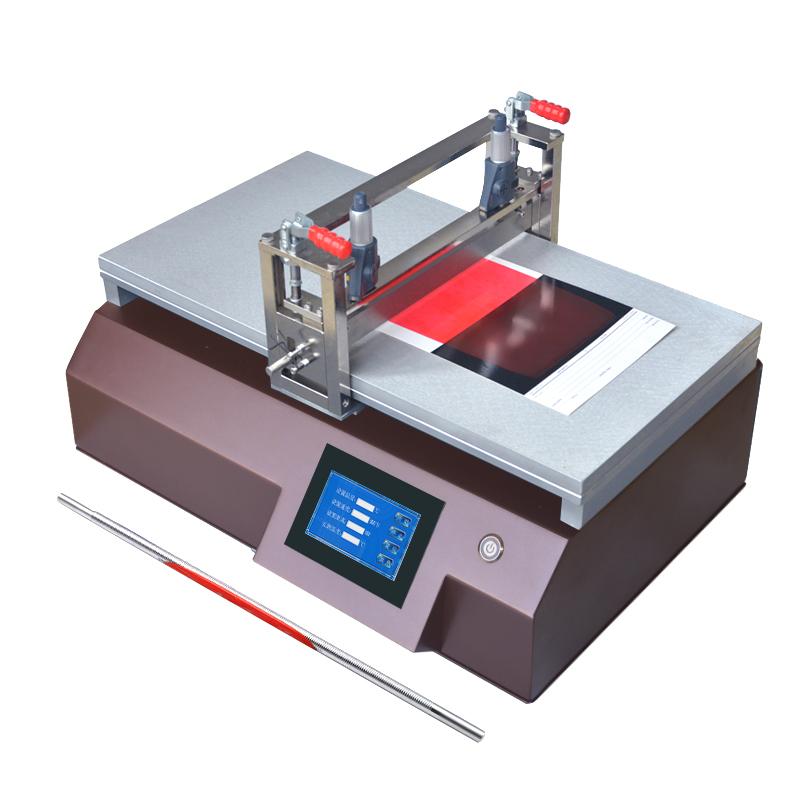

Modern laboratory Film Applicators are often equipped with advanced control systems that enable precise control of the coating process. This includes temperature control, humidity control, coating thickness control, etc. When selecting, you need to pay attention to the performance of the machine's control system to ensure that it meets the experimental needs.

2. Application fields

Optoelectronics

In the field of optoelectronics, laboratory thin Film Applicators are often used to prepare photovoltaic cells, photoDetectors and other devices. Through precision coating technology, precise control of optoelectronic materials can be achieved and the performance and stability of the device can be improved.

material science

Laboratory thin Film Applicators are widely used in materials science research. For example, it is used to prepare films with special structures and properties to study their conductive, magnetic, optical, etc. properties.

energy storage

In the field of energy storage, laboratory thin Film Applicators are widely used to prepare energy storage devices such as lithium-ion batteries and supercapacitors. Through precision coating processes, the electrochemical properties of electrode materials can be improved, thereby improving the efficiency and cycle life of energy storage devices.

Biomedical Science

In the field of biomedicine, laboratory thin Film Applicators can be used to prepare biomedical devices such as biosensors and drug releasers. By uniformly coating biomaterials on substrates, precise control of biodevice performance can be achieved.

3. Selection method

1. Material requirements analysis

Before selecting, it is necessary to clarify the type of film material required by the laboratory. Different laboratory Film Applicators are suitable for different types of materials, such as organic materials, metal materials, semiconductor materials, etc.

2. Coating method selection

Choose the appropriate coating method according to experimental needs. If the laboratory mainly studies organic materials, you can choose spin coating or spraying methods; if you study inorganic materials, methods such as ion beam sputtering may be more suitable.

3. Coating speed and uniformity requirements

Determine the requirements for coating speed and uniformity according to the purpose of the experiment. If you need high-efficiency experiments, choose a machine with a higher coating speed; if you have strict requirements on film uniformity, you should choose a coating machine with good uniformity.

4. Control system performance

Pay attention to the performance of the coater's control system to ensure it can meet the specific requirements of the laboratory. Including temperature control range, humidity control accuracy, coating thickness control accuracy, etc.

5. Maintenance and service support

Consider the maintenance and service support of the coater. Choose a manufacturer with good after-sales service and technical support to ensure that problems can be solved in time during use.

in conclusion

Laboratory film coating technology plays an important role in many fields, and as the core equipment for realizing this technology, the selection of laboratory film coating machine is crucial. This article reviews the technical characteristics, application fields and selection methods of laboratory thin film coating machines, hoping to provide a reference for researchers in related fields and provide support for the further development of laboratory thin film coating technology.