Summary:

This article will introduce the technical principles, application fields and key technical features of the coating and lamination experimental machine. Coating and lamination is an important surface treatment technology, widely used in the preparation of functional films, coatings and composite materials. The coating and lamination testing machine is the key experimental equipment used to simulate and study this process. The article will deeply discuss the structure, working principle, performance indicators and future development direction of the coating and lamination experimental machine, aiming to provide researchers with comprehensive technical understanding and experimental guidance.

Part One: Introduction

Coating and laminating technology is a surface treatment method that bonds coatings or films to substrates. It is widely used in electronics, optics, medical, food packaging and other fields. The coating and bonding experimental machine is a key equipment for related research and development. By simulating real process conditions, it helps researchers gain an in-depth understanding of the key parameters and influencing factors in the coating and bonding process.

Part 2: Structure and working principle of coating and laminating experimental machine

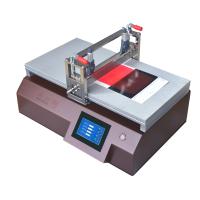

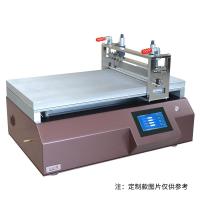

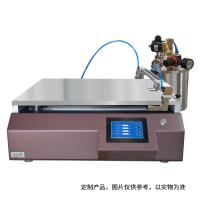

Coating and laminating testing machines usually consist of four parts: coating system, laminating system, auxiliary system and control system. The coating system is responsible for spreading the coating evenly on the surface of the substrate, while the laminating system ensures that the coating is firmly adhered to the substrate. The auxiliary system includes auxiliary functions such as temperature control and tension control, while the control system is the brain of the entire equipment, responsible for coordinating the work of various systems and ensuring the accuracy and repeatability of experiments.

The coating system generally consists of a coating head, coating roller, coating knife, etc. The coating head is one of the key components in the coating and lamination experimental machine. Its design directly affects the coating uniformity and lamination effect. Different coating head designs are suitable for different coating materials and process requirements. The coating roller spreads the coating evenly on the substrate through rotating motion, while the coating knife is used to adjust the thickness of the coating layer.

The laminating system generally consists of a pressure roller, a tension control device, etc. During the lamination process, the pressure roller ensures a good bond between the coating and the substrate through a certain amount of pressure, while the tension control device is used to adjust the tension of the substrate to ensure the smooth progress of the entire coating and lamination process.

Part 3: Performance indicators and application areas

The performance indicators of the coating and lamination testing machine directly affect the accuracy and reliability of the experiment. Common performance indicators include coating uniformity, coating speed, laminating pressure, tension control accuracy, etc. The improvement of these indicators can effectively improve experimental efficiency and reduce production costs.

Coating and laminating technology is widely used in various fields. In the field of electronics, coating and lamination technology is used to prepare flexible electronic devices, such as flexible displays, flexible batteries, etc. In the medical field, coating and laminating technology is used to prepare biomedical materials, such as medical laminating films, drug release films, etc. In the field of food packaging, coating and lamination technology is used to prepare packaging materials with functions such as moisture-proof, oxygen-proof, and fresh-keeping.

Part 4: Key technical features and future development directions

As a key research tool for coating and bonding technology, the coating and bonding testing machineâs future development direction is mainly reflected in the following aspects:

Automation and intelligence: With the continuous development of science and technology, coating and bonding experimental machines will develop in the direction of automation and intelligence, realizing automatic control and real-time monitoring of the coating and bonding process.

Versatility: Future coating and lamination testing machines will pay more attention to multi-functional design to adapt to the needs of different materials and processes and achieve flexibility and versatility in coating and lamination.

Green and environmental protection: As society's requirements for environmental protection continue to increase, future coating and lamination testing machines will pay more attention to the research and development of green and environmentally friendly technologies to reduce the impact on the environment.

Research on high-performance materials: With the continuous advancement of materials science, coating and lamination testing machines will pay more attention to the research of high-performance materials to meet the requirements for material performance in advanced application fields.

Industrial application: Coating and laminating technology is a key surface treatment technology. In the future, coating and laminating experimental machines will pay more attention to close integration with industry and promote the industrial application of technology.

in conclusion

Through an in-depth discussion of the technical principles, application fields, key technical features and future development directions of the coating and laminating experimental machine, we can see the importance and broad application prospects of coating and laminating technology in various fields. As a key tool to support this technology, the coating and laminating experimental machine will provide more advanced and efficient experimental methods for researchers in related fields through its continuous technological innovation and development, and promote the continuous progress of coating and laminating technology.