Summary:

Hot melt adhesive coating technology has been widely used in various fields. Among them, laboratory coaters are an important tool for research and development, and their performance and technical level have an important impact on the application and improvement of hot melt adhesives. This article will deeply explore the working principle, key technologies and practical effects of hot melt adhesive laboratory coating machines in scientific research and industrial applications, aiming to provide in-depth understanding and reference for researchers in related fields.

I. Introduction

Hot melt adhesive is a colloidal material with high viscosity, high adhesion and fast curing properties. It is widely used in packaging, medical, electronics, automobile and other fields. As an important tool for the research and development of new hot-melt adhesive materials, the laboratory coater's performance and technical level are crucial to promoting the development of hot-melt adhesive technology.

2. Working principle

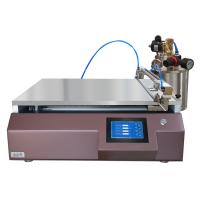

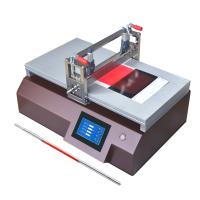

Hot melt adhesive laboratory coating machine mainly consists of glue machine, coating mechanism, transmission system, control system and other parts. Its working principle is based on the fluidity of hot melt adhesive at a certain temperature. Through a precise control system, the hot melt adhesive can be evenly coated.

1. Glue machine

The glue machine is the core component of the laboratory coating machine. Its task is to heat the solid hot melt adhesive to a liquid state and transport it to the coating mechanism through pipelines. The heating system of the glue machine adopts advanced electric heating technology to ensure that the hot melt adhesive can maintain fluidity at a suitable temperature.

2. Coating mechanism

The coating mechanism includes components such as a coating roller and a pressure roller. Its task is to evenly coat the hot melt adhesive on the surface of the substrate to be treated. The design and surface treatment of the coating roller have an important impact on coating quality, and it is necessary to ensure coating uniformity and stability.

3. Transmission system

The transmission system is responsible for realizing the movement of the coating mechanism and ensuring that the hot melt adhesive is evenly covered on the substrate. The high-precision transmission system can improve the accuracy and consistency of coating.

4. Control system

The control system is the brain of the laboratory coating machine. It achieves precise coating of hot melt adhesive through precise control of parameters such as temperature, speed, and pressure. The advanced control system can also record and analyze experimental data, providing strong support to researchers.

3. Key technologies

The performance and effect of hot melt adhesive laboratory coating machines are affected by a variety of key technologies, including the heating technology of the glue machine, the design of the coating mechanism, the accuracy of the transmission system, and the intelligence of the control system.

Heating technology

The heating technology of the glue machine directly affects the fluidity and stability of the hot melt adhesive. At present, advanced electric heating technology can achieve rapid and uniform heating and avoid quality problems caused by uneven temperature of hot melt adhesive.

Coating mechanism design

The design of the coating mechanism needs to take into account the viscosity and fluidity of the hot melt adhesive as well as the characteristics of the substrate. The optimized design can improve the uniformity and stability of coating and avoid problems such as bubbles and defects during the coating process.

Transmission system accuracy

The accuracy of the transmission system is directly related to the accuracy and consistency of coating. The use of a high-precision transmission system can ensure that the hot melt adhesive is evenly covered on the substrate and improve the reliability of experimental data.

Intelligent control system

The intelligence of the control system is one of the development trends of hot melt adhesive laboratory coating machines. Through advanced sensors, automation algorithms and data analysis technology, real-time monitoring and adjustment of the coating process can be achieved to improve experimental efficiency and accuracy.

4. Application of hot melt adhesive laboratory coating machine in scientific research

Hot melt adhesive laboratory coating machines have been widely used in the field of scientific research, mainly reflected in the following aspects:

Research on new hot melt adhesive materials

Laboratory coaters provide researchers with a convenient tool for preparing and testing new hot melt adhesive materials. By adjusting the parameters of the coating machine, researchers can obtain hot melt adhesives with different formulas and properties, making it possible to innovate hot melt adhesive materials.

Research on the application of hot melt adhesive on different substrates

The laboratory coater can achieve uniform coating of hot melt adhesive on different substrates, providing researchers with a platform to study the adhesion, adhesion and other properties of hot melt adhesive on different materials. This is of great significance for optimizing the application of hot melt adhesives in different fields.

Optimization of hot melt adhesive process parameters

By precisely adjusting the control system of the laboratory coater, researchers can optimize the coating process parameters of hot melt adhesive, including temperature, speed, pressure, etc. This helps improve the efficiency and quality of hot melt adhesive coating and reduce production costs.

Application of hot melt adhesive in micro-nano technology

Laboratory coaters are increasingly used in micro and nanotechnology. Through the design of a tiny coating head and a high-precision control system, the laboratory coater can achieve precise coating of tiny areas, providing technical support for the preparation of micro-nano devices.

5. Application of hot melt adhesive laboratory coating machine in industry

In addition to scientific research, hot melt adhesive laboratory coating machines are also widely used in industry, mainly in the following aspects:

Packaging industry

Hot melt adhesive is widely used in the packaging industry, and laboratory coating machines provide an effective means for the research and development of packaging materials. Through the laboratory coater, researchers can simulate the performance of hot melt adhesives under different packaging conditions and optimize the packaging process.

it

In the electronics industry, hot melt adhesive is used for packaging and fixing electronic components. Laboratory coaters can help researchers explore the coating effect of hot melt adhesive on the surface of electronic components and improve the reliability and durability of electronic devices.

Car manufacturer

Hot melt adhesives are also widely used in automobile manufacturing, for example in the bonding of automobile interior parts. The laboratory coater can be used to study the hot melt adhesive coating effects of different materials in the automobile manufacturing process, providing technical support for improving the automobile manufacturing process.

medical instruments

In medical device manufacturing, hot melt adhesives are used for fixation and encapsulation. Laboratory coaters can help researchers optimize the coating process of hot melt adhesives to ensure the quality and safety of medical devices.

6. Conclusion

Hot melt adhesive laboratory coater is an important tool for the research and application of hot melt adhesive technology. Through in-depth discussions on its working principle, key technologies, applications in scientific research and industry, and future development directions, we have conducted experiments on hot melt adhesive Chamber coater has a more comprehensive understanding. In the future, with the continuous advancement of technology and the increasing demand, hot melt adhesive laboratory coaters are expected to play a greater role in various fields and promote the continuous innovation and development of hot melt adhesive technology.