With the continuous development of science and technology, laboratory coating machines, as an advanced coating equipment, have been widely used in various fields. This article will focus on the technological progress and advantages of laboratory coaters in the application of double-sided tape, including coating technology, material selection, process parameter optimization, etc., aiming to provide useful reference for research and application in related fields.

introduction

As an adhesive with excellent adhesion properties, double-sided tape occupies an important position in modern manufacturing. As an efficient and precise coating equipment, the laboratory coater provides more reliable tools and technical support for the preparation of double-sided tape. This article will conduct an in-depth study of the technological progress of laboratory coaters in the application of double-sided tape, and explore its advantages in improving production efficiency, optimizing process parameters, and expanding application areas.

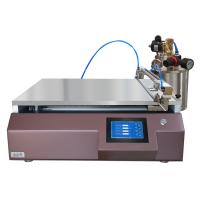

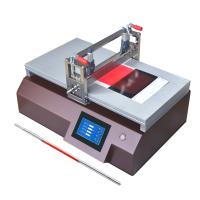

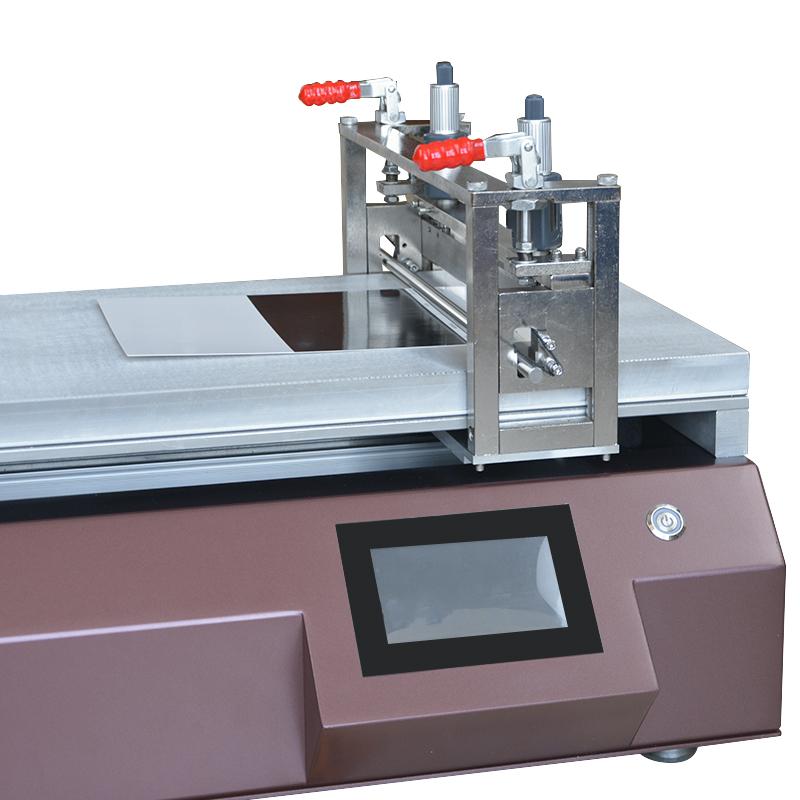

Basic principles of laboratory coater

Laboratory coater is a device that coats liquid or paste materials on substrates. Its basic principles include coating head, substrate conveying system, control system, etc. In the application of double-sided tape, the design of the coating head and the choice of coating method are crucial. Common coating methods include uniform coating, mesh coating, dot coating, etc. Choosing the appropriate coating method according to the specific needs of the double-sided tape can effectively improve the coating quality and adhesion.

Technical progress of laboratory coater in double-sided tape application

Innovation in coating technology

With the continuous advancement of science and technology, coating technology has also been continuously innovated in laboratory coating machines. The introduction of emerging technologies such as microfluidic technology and nano-coating technology has made the coating of double-sided tape more precise and uniform. Microfluidic technology can achieve precise control of tiny particles, thereby improving the adhesion and durability of double-sided tape.

Optimization of material selection

The performance of double-sided tape is closely related to the choice of materials. In the application of double-sided tape, the laboratory coater can improve the adhesion performance, shear resistance, etc. of the double-sided tape by optimizing material selection. The development and introduction of new adhesives enable double-sided tape to perform well in various special environments.

Optimization of process parameters

In the operation of laboratory coating machines, reasonable process parameter settings are the key to ensuring the quality of double-sided tape coating. Reasonable control of coating speed, temperature, humidity and other parameters can effectively reduce the error rate during the coating process and improve production efficiency. The advanced control system makes operation easier and enables real-time monitoring and adjustment of the coating process.

Analysis of the advantages of laboratory coater in double-sided tape application

Improvement of production efficiency

The efficient coating method and advanced control system of the laboratory coater have significantly improved the production efficiency of double-sided tape. Compared with traditional manual coating, the laboratory coating machine can not only realize automated production, but also ensure the uniformity and consistency of coating and improve production efficiency.

Guarantee of quality stability

The laboratory coating machine ensures the quality stability of double-sided tape through precise coating head design and highly controllable process parameters. During the coating process, the coating quality can be monitored in real time and the process parameters can be adjusted in time to ensure that each piece of double-sided tape has consistent performance indicators.

Expansion of diverse applications

The flexibility of the laboratory coater has expanded the application fields of double-sided tape more widely. Different coating methods, different material selections and adjustment of process parameters allow double-sided tape to not only be used in traditional pasting and fixing fields, but also play a more important role in electronics, medical, aerospace and other fields.

in conclusion

The technological progress of laboratory coaters in the application of double-sided tape provides more efficient and precise coating tools for production and manufacturing. Through the innovation of coating technology, optimization of material selection and adjustment of process parameters, the laboratory coater not only improves production efficiency, but also ensures the quality stability of double-sided tape. However, in-depth research is still needed in terms of technical challenges, environmental friendliness, and expansion of application fields to meet the evolving production needs and environmental protection requirements. The advantages and challenges of laboratory coaters in double-sided tape applications will jointly promote the continuous development and innovation in this field.