introduction

With the rapid development of science and technology, all walks of life are constantly pursuing automated and intelligent production methods to improve production efficiency and reduce costs. In the field of printing and coating, micro-coil automatic coating machines are one of the products of this trend. This article will conduct an in-depth analysis of the technology of micro-coil automatic coating machines and compare it with traditional roll-to-roll coating machines to highlight the advantages of micro-coil automatic coating machines.

1. Basic principles of micro coil automatic coating machine

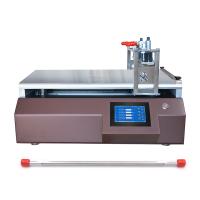

Micro coil automatic coating machine is a special equipment widely used in printing, coating, electronics and other industries. It is mainly composed of roll conveying system, coating system, drying system and control system.

Coil transfer system: The roll transfer system of the micro-coil automatic coating machine adopts advanced drive technology, which can accurately control the transfer speed and tension of the roll. The conveyor system usually includes roll-up and unwind devices, which work together through motors, sensors and other equipment to ensure stable conveyance of the roll.

Coating system: The coating system is the core part of the micro coil automatic coating machine. It uses a high-precision coating head to achieve precise spraying of the coating agent through pneumatic or electric control. Compared with traditional manual coating, automatic coating machines can achieve more uniform and stable coating effects.

Drying system: After coating is completed, the coil needs to be dried to ensure rapid curing of the coating agent. The drying system of the micro coil automatic coating machine adopts advanced hot air circulation technology, which can quickly and evenly solidify the coating agent on the surface of the coil to improve production efficiency.

Control system: The control system is the brain of the micro coil automatic coating machine. It realizes automatic control of the entire coating process through PLC (programmable logic controller) or other advanced controllers. Operators can set and monitor parameters through the human-machine interface (HMI), making the production process more intelligent.

2. The difference between micro coil automatic coating machine and roll-to-roll coating machine

Compared with traditional roll-to-roll coating machines, micro-coil automatic coating machines have some significant differences in technical principles and applications.

First of all, the micro coil automatic coating machine is a highly automated equipment that can realize fully automated operations from coil transfer, coating to drying. Roll-to-roll coating machines usually require more manual operations, including adjusting the position of the coating head, controlling the web tension, etc., and have a low degree of automation.

Second, the micro coil automatic coating machine adopts advanced coating head technology, which can achieve high-precision coating and have good uniformity and stability of the coating agent. The roll-to-roll coater has relatively low coating accuracy and is prone to uneven coating.

Third, due to its high degree of automation and superior coating accuracy, micro coil automatic coating machines have obvious advantages in production efficiency. It can achieve a fast production cycle and adapt to high-intensity, high-volume production needs. In contrast, roll-to-roll coating machines have lower production efficiency and are suitable for small batch, low-capacity production scenarios.

Fourth, micro coil automatic coating machines are widely used in electronics, printing and other fields, especially for products that require small coils and high-precision coating. The roll-to-roll coating machine is mainly used in some more traditional printing and packaging fields, and products with relatively low coating requirements.

3. Technical advantages of micro coil automatic coating machine

As an important part of modern production lines, micro coil automatic coating machines have many technical advantages, making them widely used in the market.

The micro coil automatic coating machine adopts advanced coating head technology to achieve high-precision and uniform coating effects. This provides a reliable solution for some products that require extremely high coating quality, such as electronic components.

The micro coil automatic coating machine has a high degree of automation in the entire production process, reducing the possibility of manual intervention, improving production efficiency, and reducing production costs.

The micro coil automatic coating machine is suitable for various combinations of materials and coating agents and has strong adaptability. This allows it to be widely used in production processes in different industries.

The micro coil automatic coating machine can quickly switch production tasks of different specifications and needs, achieving flexibility and diversification of the production line.

4. Application fields of micro coil automatic coating machine

Micro coil automatic coating machines have a wide range of applications, mainly involving electronics, printing, film materials and other industries.

Electronics industry: Micro coil automatic coating machines are widely used in the electronics industry for the coating process of small coils such as PCB boards and circuit boards to ensure precise coating of electronic components.

Printing industry: In the printing industry, micro coil automatic coating machines can be used in printing ink, lamination and other processes to improve the quality and production efficiency of printed matter.

Thin film materials: For some thin film materials that require extremely high coating uniformity and thickness, micro coil automatic coating machines can provide reliable solutions to ensure product quality.

5. Future development trends of micro coil automatic coating machines

With the continuous advancement of technology, micro coil automatic coating machines are expected to usher in more innovation and development in the future.

Intelligent: The future micro coil automatic coating machine will be more intelligent, using artificial intelligence, machine learning and other technologies to achieve a more intelligent production process and independent adjustment.

Energy saving and environmental protection: In terms of the selection and use of coating agents, future micro coil automatic coating machines will pay more attention to energy saving and environmental protection, using more environmentally friendly coating agents to reduce the impact on the environment.

Higher production efficiency: With the continuous advancement of mechanical and electronic technology, future micro coil automatic coating machines will achieve higher production efficiency and shorter production cycles to meet the market's demand for efficient production.

Wider application areas: In the future, micro coil automatic coating machines will be more suitable for the production needs of different industries, expand application fields, and meet diversified market demands.

in conclusion

As an important equipment in modern production lines, micro coil automatic coating machines provide reliable coating solutions for industries such as electronics, printing, and film materials through its technical advantages such as high automation and high-precision coating. Compared with traditional roll-to-roll coating machines, micro-coil automatic coating machines have obvious advantages in coating accuracy, automation, and production efficiency, and have gradually become a development trend in the industry. With the continuous advancement of science and technology, in the future, micro coil automatic coating machines are expected to usher in more innovation and development in terms of intelligence, energy conservation and environmental protection, and wider application fields.