introduction

As a common coating material, paint is widely used in construction, automobile, furniture and other industries. The fluidity and coating performance of the coating are crucial to the coating effect. In order to accurately evaluate the fluidity and coating performance of coatings, the coating fineness scraper is widely used as an important experimental tool. This article will deeply explore the principle, structure, usage, application scenarios and future development trends of the paint fineness scraper, so that readers can better understand and apply this key tool.

Fundamental

The coating fineness squeegee is a tool used to evaluate the fluidity and coating performance of coatings. The principle is based on the flow behavior of the coating on the squeegee. In the test, the paint is evenly applied on a flat substrate, and then a scraper is used to scrape the paint off the substrate to form a standard thickness film. By scraping the fluidity and coating performance of the coating, various performance indicators of the coating can be obtained, such as fluidity, coating rate, etc.

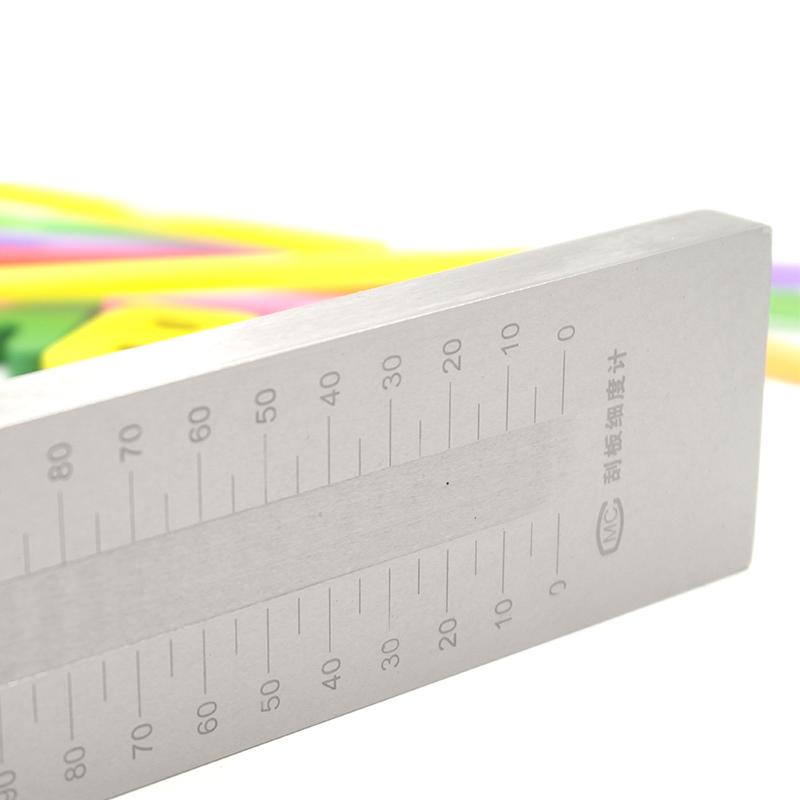

The paint fineness scraper usually consists of two parts: a scraper and a base. Scrapers are usually made of stainless steel or other corrosion-resistant materials and have a certain degree of rigidity and flatness. The size of the scraper and the width of the scraper are different, and scrapers of different specifications can be selected according to needs. The base usually consists of a stable support structure and an adjustment device, which is used to fix the scraper and adjust the gap between the scraper and the substrate to control the scraping thickness of the paint.

Application scenarios

In the coating production process, the coating fineness scraper can be used to evaluate the fluidity and coating performance of the coating, and guide the production process and quality control. In the coating research and development process, the coating fineness scraper can be used to compare the performance differences of coatings with different formulas and optimize the coating formula and process parameters. During the quality inspection of paint products, the paint fineness scraper can be used to check the coating uniformity and coating thickness to ensure that product quality meets standard requirements. During the coating process, the coating fineness scraper can be used to evaluate the coating performance of the coating and guide the optimization and adjustment of the coating process.

With the development of science and technology, future paint fineness scrapers may incorporate automation technology to realize automated operations of paint coating, scraping and measurement, and improve testing efficiency and accuracy. Future coating fineness scrapers may integrate more functions, such as automatic cleaning, multi-angle scraping, online data monitoring, etc., to meet the needs of different industries and application scenarios. Future paint fineness scrapers may add intelligent data analysis functions to realize automated analysis and optimization of paint performance data through artificial intelligence and big data analysis technology.

Conclusion

As an important tool for evaluating the fluidity and coating performance of coatings, the coating fineness scraper has important application value and development prospects. By in-depth understanding of its principles, structure, usage, application scenarios and future development trends, we can better understand and apply this key tool and promote the development and innovation of the coatings industry.