Spray coater and knife coater are two common coating equipment in the coating field. They have some significant differences in coating process, applicable fields, coating effects, etc. This article will provide an in-depth analysis of spray coaters from a technical perspective and compare them with knife coaters to better understand their differences and advantages and disadvantages in industrial applications.

Part One: Technical Analysis of Spray Coating Machine

1. Basic principles of spray coating machine

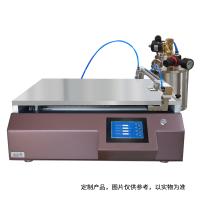

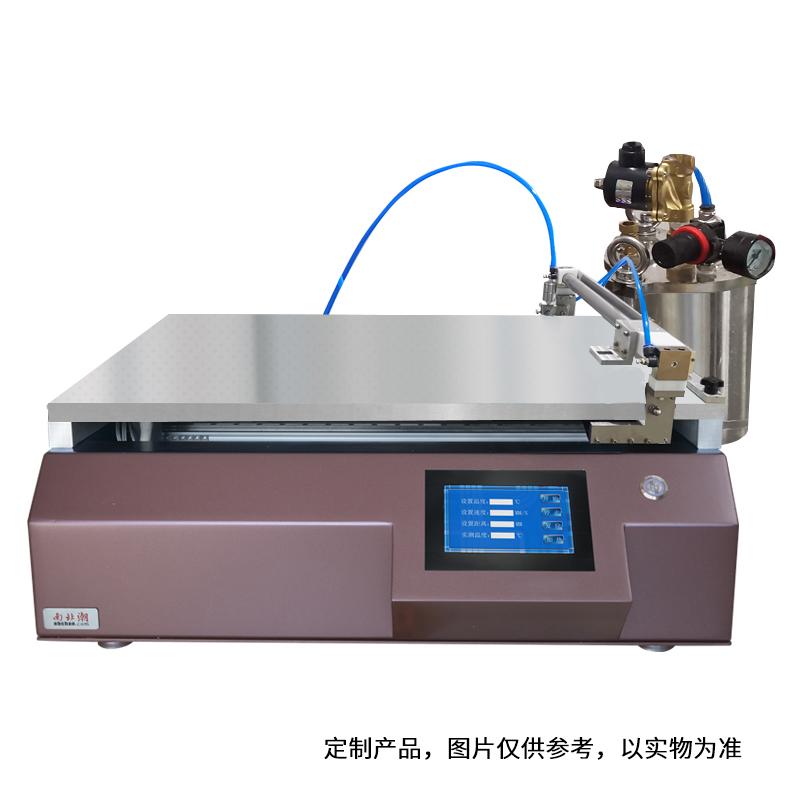

A spray coater is a device that completes coating by spraying paint in the form of gas or liquid onto the surface of a substrate. The basic principle is to use the high-speed airflow generated by the nozzle to atomize the paint into small particles, and then spray it evenly on the substrate. Spray coating machines usually include Spray Guns, compressed air systems, paint supply systems, etc.

2. Advantages of spray coating machine

2.1 High efficiency

The spray coater can apply paint quickly and evenly, improving production efficiency. Since the paint is sprayed in atomized form, the coating time is relatively short and is suitable for large-area coating.

2.2 Strong adjustability

The coating thickness, spray speed and other parameters of the spray coating machine can be accurately controlled by adjusting the equipment, which is suitable for different coating needs.

2.3 Suitable for substrates with complex shapes

Since spraying sprays paint onto the substrate through airflow, it is suitable for a variety of substrates with complex shapes, including concave and convex surfaces and curved surfaces.

3. Application fields of spray coating machine

3.1 Automobile manufacturing

Spray coating machines are widely used in automobile manufacturing for coating automobile bodies, parts, etc. Its high efficiency and precise control make it ideal for mass production.

3.2 Electronic products

Spray coating machines are also commonly used for exterior coating of electronic products, such as mobile phone cases, computer cases, etc. Its strong adjustability meets the coating requirements of different products.

3.3 Architectural decoration

In the construction field, spray coating machines can be used for the construction of indoor and outdoor wall coatings, waterproof coatings, etc., improving construction efficiency and coating quality.

Part 2: Technical Analysis of Blade Coater

1. Basic principles of knife coating machine

The blade coater is a device that evenly applies paint to the surface of the substrate in a film shape to complete the coating. The basic principle is to spread the paint flatly on the substrate through a scraper or roller to form a uniform coating.

2. Advantages of knife coating machine

2.1 Suitable for high viscosity coatings

The blade coater is suitable for high-viscosity coatings and can form a relatively uniform film on the substrate, making it suitable for some occasions that require thicker coatings.

2.2 Suitable for small batch production

The coating method of the blade coater is relatively simple, suitable for small-scale and small-batch production, and does not require large-scale coating equipment.

2.3 No spray generated

Compared with spray coating machines, blade coating machines do not produce spray, which reduces paint waste and is suitable for some occasions that require higher coating environment.

3. Application fields of knife coating machine

3.1 Packaging materials

Blade coating machines are often used for coating packaging materials, such as cartons, packaging films, etc., which meet the requirements for coating uniformity and adhesion.

3.2 Printing industry

In the printing industry, blade coaters are often used for ink coating to ensure the quality and color uniformity of printed matter.

3.3 Woodworking industry

Blade coaters are also widely used in the woodworking industry for coating wood products, such as furniture, floors, etc.

Part 3: Comparison between Spray Coater and Blade Coater

1. Differences in coating methods: The spray coating machine uses atomization spraying to form a uniform film; the blade coating machine spreads the paint smoothly through a scraper or roller to form a coating of a certain thickness.

2. Differences in applicable coatings : Spray coating machines are suitable for coatings with low to high viscosity, while blade coating machines are more suitable for coatings with high viscosity.

3. Differences in applicable fields : Spray coating machines are suitable for large-area, high-efficiency coating and are commonly used in automobile manufacturing, electronic products and other fields; blade coating machines are suitable for small batch production and are commonly used in packaging materials and printing industries. , woodworking industry, etc.

4. Difference in production efficiency : Spray coating machine has high production efficiency due to its atomized spraying method and is suitable for large-scale production; blade coating machine is suitable for small-scale production and has relatively low production efficiency.

5. Differences in cost and equipment complexity : Spray coating machines usually require more complex equipment and control systems, with higher costs; blade coating machines are relatively simple, with lower costs.

in conclusion

Spray coaters and blade coaters each have unique advantages and applicable fields. Choosing the right coating equipment depends on factors such as production needs, coating materials, and budget. In practical applications, choosing according to specific circumstances and combining the advantages of both can better meet the coating needs of different industries.