Roll-to-roll coating technology plays an important role in modern industry, especially in the production of composite materials. This article will deeply explore the technical characteristics of roll-to-roll small coating lamination machines, and conduct a comparative study with traditional roll-to-roll coating machines, aiming to reveal the advantages and applicable scenarios of small roll-to-roll coating machines.

introduction

Roll-to-roll coating technology is a method of coating on a continuous production line and is widely used in paper, plastics, metal and other industries. In recent years, with the continuous development of science and technology, small coating lamination machines have gradually emerged and become the new favorite in the production process. This article will elaborate on the technical principles, application fields, advantages, etc. of small coating composite machines, and conduct a comprehensive comparison with traditional roll-to-roll coating machines.

Technical principles of roll-to-roll small coating lamination machine

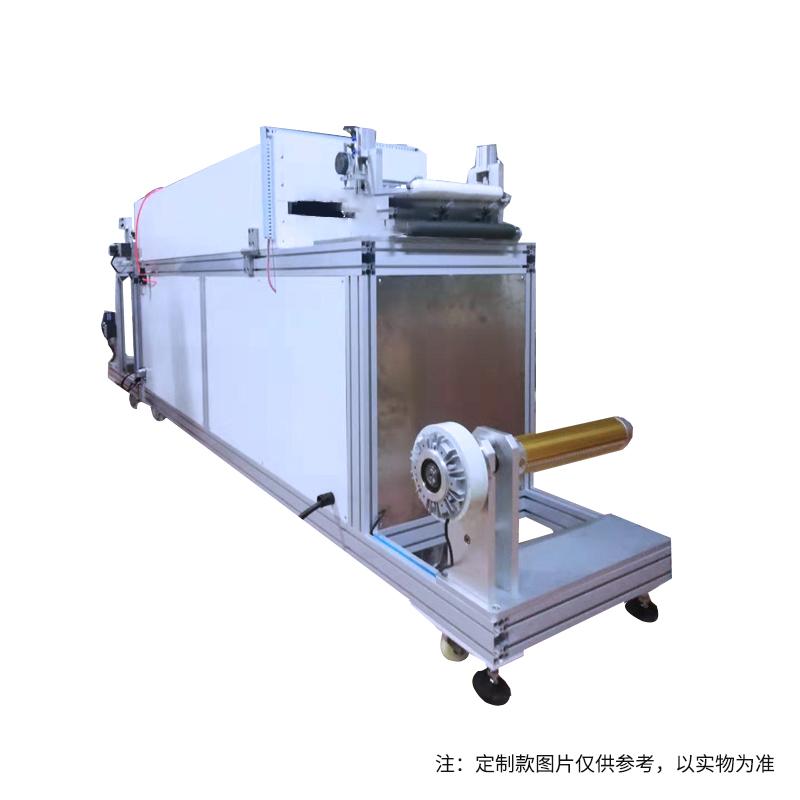

The technical principles of roll-to-roll small coating lamination machine mainly include coating system, drying system and lamination system. The coating system applies the coating evenly to the substrate through rollers or spraying, the drying system quickly dries the coated material, and the composite system realizes the composite of different materials. This series of technical principles work together to ensure the efficient and stable operation of the production line.

Application fields of roll-to-roll small coating lamination machine

Small coating compound machines are suitable for many fields due to their small size, high production efficiency, and easy operation. For example, the food packaging industry can use small coating laminating machines to produce packaging materials with moisture-proof and oil-proof properties; the medical device field can use small coating laminating machines to prepare products such as medical tape; the electronics industry can use them to prepare flexible circuit boards, etc.

Comparative study of roll-to-roll small coating lamination machine and traditional roll-to-roll coating machine

4.1 Comparison of technical features

Traditional roll-to-roll coaters are usually bulky and require larger production space, while small coating lamination machines are more compact and suitable for factories with limited space. At the same time, small machines usually have more flexible operability and are easier to adjust and maintain.

4.2 Production efficiency comparison

Since small-scale coating lamination machines usually adopt advanced automatic control systems, their production efficiency is high and they can better adapt to the production needs of small batches and multiple varieties. Traditional coaters may be better at handling large-scale production, but they may fall short in terms of flexibility and rapid response to market demands.

4.3 Cost comparison

Small coating lamination machines are relatively low-cost due to their small size. In addition, its efficient production methods also result in relatively low operating costs. Although traditional roll-to-roll coaters have certain advantages in mass production, their investment and operating costs are high.

Conclusion and Outlook

This article reveals the importance and advantages of small-scale coating composite machines in modern industry through a comparative study of the technical characteristics, application fields and traditional roll-to-roll coating machines of small roll-to-roll coating machines. In the future, with the continuous innovation of science and technology, small coating composite machines are expected to be widely used in more fields, bringing more convenience and benefits to industrial production.