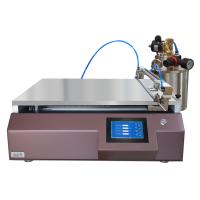

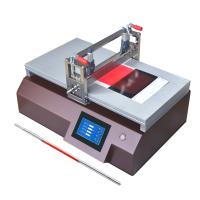

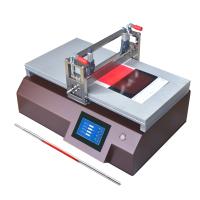

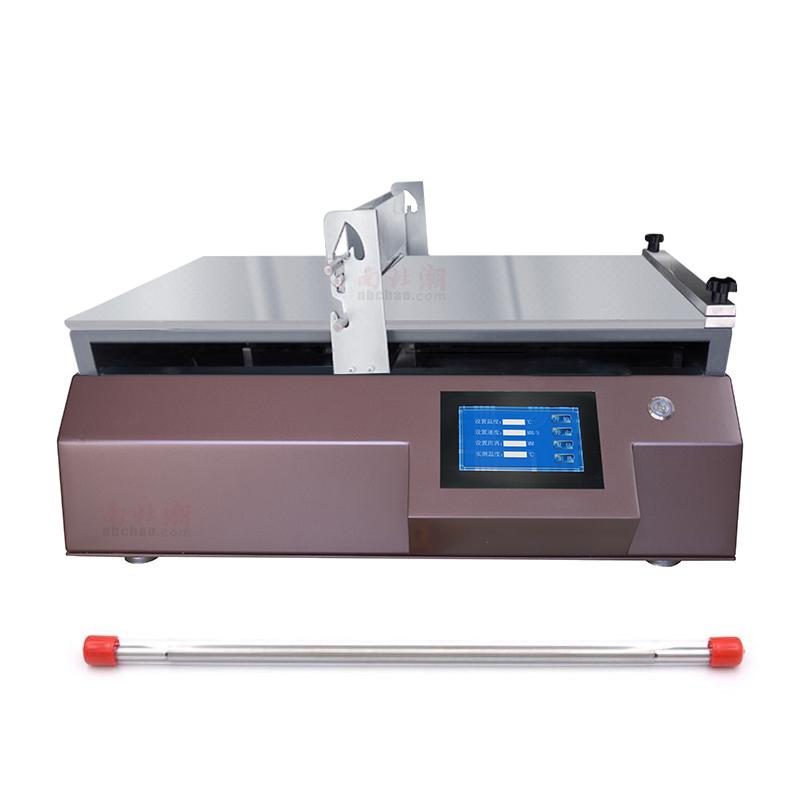

The separator coater is an advanced coating equipment that is widely used in multiple industries, including battery manufacturing, new energy, semiconductors and other fields. This article will delve into the working principle, technical characteristics, application fields and other aspects of the membrane coating machine to provide readers with a detailed understanding.

1. Working principle of diaphragm coating machine

The separator coater is mainly used for coating battery separators in battery manufacturing. The battery separator is located between the positive and negative electrodes and serves to isolate the positive and negative electrodes of the battery. The working principle of the coating machine mainly includes the following steps:

Before the coating machine starts working, it is first necessary to accurately position the bottom film of the battery separator to ensure the accuracy of the subsequent coating process.

The diaphragm coater uses a precise control system to evenly coat the coating on the surface of the diaphragm. The coating process needs to consider factors such as the viscosity, fluidity and coating speed of the coating to ensure the uniformity and quality of the coating.

The coated separator needs to be dried to ensure that the coating can firmly adhere to the surface of the separator. High temperatures or other specific drying methods are often used to ensure the stability of the coating.

After coating and drying, the separator is precisely rolled up for subsequent cutting and packaging.

Through this series of work steps, the separator coating machine achieves efficient coating of battery separators to ensure battery performance and stability.

2. Technical characteristics of diaphragm coating machine

The membrane coater is equipped with an advanced control system that enables high-precision control of the coating process. Through precise adjustment of parameters such as coating speed and coating thickness, it is ensured that each battery separator can meet the coating quality required by the design. Separator coaters are often versatile and can accommodate different types and sizes of battery separators. This flexibility allows the coater to meet the needs of different industries and applications, improving the versatility and adaptability of the equipment. In addition, the membrane coating machine has a high degree of automation, which greatly improves the efficiency of coating production. High-speed coating and automated control systems make the coating process faster and more stable, reducing production costs.

Moreover, advanced membrane coaters are usually equipped with quality monitoring systems that can monitor coating quality in real time and detect and correct possible problems in a timely manner. This helps improve the consistency and stability of production and reduces the rate of defective products. Membrane coaters are usually designed and manufactured with energy saving and environmental protection factors in mind. Use high-efficiency heating systems, exhaust gas treatment equipment, etc. to reduce energy consumption and impact on the environment.

3. Application fields of diaphragm coating machine

Separator coaters are widely used in battery manufacturing, new energy, semiconductor and other fields. Their application scope includes but is not limited to:

Lithium battery manufacturing: The separator coater is an indispensable key equipment in the lithium battery production line. Through efficient coating of lithium battery separators, the performance and cycle life of lithium batteries are improved.

Fuel cells: In the fuel cell production process, separator coaters also play an important role. Ensuring the coating uniformity of the fuel cell separator is directly related to the output performance of the fuel cell.

Flexible electronics: Separator coaters are also widely used in the field of flexible electronics, used to prepare flexible electronic devices such as flexible batteries and flexible displays.

Semiconductor manufacturing: The separator coater can also take advantage of its high-precision coating in semiconductor manufacturing, especially in the photoresist coating process.

Energy storage: The separator coating machine can also take advantage of its coating technology in the production of other energy storage devices, such as supercapacitors.

As a key manufacturing equipment, membrane coater has important applications in various fields. Through its technical features such as high-precision control, versatility, efficient production and quality monitoring, membrane coaters play an increasingly important role in modern industry.