This article will conduct an in-depth study of the PU film roll automatic coating machine technology, explore its application in different fields, and analyze the significance of PU film preparation. PU film rolls are widely used in waterproof, moisture-proof, wear-resistant, insulation and other fields. The reliability of its preparation technology and the automation level of the coating machine are directly related to the quality and production efficiency of the product. Through research on PU film roll automatic coating machine technology, we can promote the development of related industries, improve production efficiency, and reduce production costs.

Part One: Introduction

1.1 Background

With the continuous development of modern industry, the demand for functional films is gradually increasing. As a high-performance, multi-functional film material, PU film is widely used in waterproof, moisture-proof, insulation, wear-resistant and other fields. In order to improve the preparation efficiency and quality of PU film rolls, automatic coating machine technology has become a research direction that has attracted much attention.

1.2 The significance of PU film preparation

PU film has excellent physical and chemical properties and is widely used in textile, construction, medical and other fields. In its preparation process, the coating process is a crucial part. Traditional manual coating has problems such as low production efficiency and difficulty in ensuring quality. The application of automatic coating machines can effectively improve the production efficiency, quality stability and consistency of PU films.

Part 2: Overview of PU film roll automatic coating machine technology

2.1 PU film preparation process

The preparation process of PU film mainly includes raw material preparation, reaction system configuration, coating, curing and other steps. Among them, coating is one of the key steps, and the coating process is directly related to the performance and quality of the PU film.

2.2 Development History of Automatic Coating Machine

Automatic coating machine technology originated in the last century. With the advancement of computer technology and mechanical control technology, automatic coating machines have developed rapidly. At present, automatic coating machines have been widely used in various industries, including textiles, automobiles, construction and other fields.

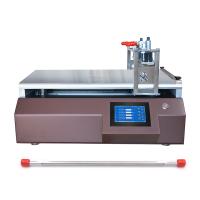

2.3 Working principle of PU film roll automatic coating machine

The PU film roll automatic coating machine mainly includes a feeding system, a coating system, a curing system and other parts. Through precise control, the coating system can achieve uniform coating of PU film and ensure product quality.

Part 3: Applications in various fields

3.1 Textile industry

PU membrane rolls are often used in the textile industry to make waterproof and breathable functional fabrics. The application of automatic coating machines can improve production efficiency and ensure product quality.

3.2 Construction industry

In the construction industry, PU membrane membranes are often used as roof waterproofing and heat insulation materials. The precise control of the automatic coating machine can ensure the coating uniformity and durability of the PU film.

3.3 Automobile industry

PU film rolls are widely used in automotive interiors and seat materials. The efficient production of automatic coating machines can meet the automotive industry's needs for large product quantities and stable quality.

Part 4: Key Technologies and Challenges

4.1 Control system

The key to the automatic coating machine lies in its control system, which needs to achieve precise control of coating thickness, speed, temperature and other parameters. Reliable control algorithms and sensing technology are key.

4.2 Coating head design

The design of the coating head directly affects the uniformity of coating, and factors such as fluid mechanics and thermodynamics need to be considered to ensure that the PU film can be evenly distributed during the coating process.

4.3 Coating material selection

The selection of coating materials is directly related to the performance of the PU film. It is necessary to select suitable coating materials in different application scenarios while considering factors such as environmental protection and cost.

in conclusion

The research and application of PU film roll automatic coating machine technology is of great significance to improving the efficiency and quality of PU film preparation. By continuously improving the coating machine's control system, coating head design and coating material selection, the development of PU film roll automatic coating machine technology can be further promoted. In the future, with the promotion of intelligence, environmental protection performance and cross-industry cooperation, PU film roll automatic coating machines will usher in broader application prospects.