In chemical, pharmaceutical, food and other fields, moisture content is one of the important indicators affecting product quality. Therefore, accurate measurement of moisture content is crucial for the control of the production process and the assurance of product quality. As an efficient and accurate moisture measurement equipment, the halogen moisture analyzer is widely used in laboratories and production sites. This article will delve into the principle, structure, and application scenarios of the halogen moisture analyzer to help readers better understand and apply this key equipment.

Principle structure

The halogen moisture analyzer uses halogen as a desiccant and uses its moisture adsorption properties to measure the moisture content in the sample. When the moisture in the sample is adsorbed by the halogen, the moisture content in the sample is calculated by weighing the mass change of the halogen.

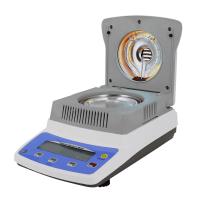

The halogen moisture analyzer mainly includes the host part, including weighing instruments, heaters, halogen desiccant containers and other components. It is mainly responsible for controlling the operation of the measuring instrument and displaying the measurement results. The heater provides a constant temperature environment, accelerates the evaporation and drying process of moisture in the sample, and improves measurement speed and accuracy. The container is equipped with a halogen desiccant, which dries the sample by heating and adsorbing moisture. The display screen is used to display measurement results and operation prompts, and the control panel provides parameter setting and operation guidance.

The halogen moisture analyzer uses a high-precision weighing instrument and a constant temperature heater to achieve accurate measurement of moisture content. The heater provides a constant temperature environment to accelerate the evaporation and drying process of water in the sample, making the measurement faster. The control panel provides an intuitive operation interface with simple parameter settings and convenient operation, making it suitable for all kinds of users. The measuring instrument has a variety of measurement modes and adjustable parameter functions to meet different sample and experimental needs.

Application scenarios

Halogen moisture analyzers are usually used in the production process of chemical products to measure the moisture content in raw materials and finished products to ensure product quality and production stability. Used for moisture measurement of pharmaceutical raw materials and preparations to ensure the stability and effectiveness of drugs. It is used to measure the moisture content of raw materials and finished products during food processing to control the taste and quality of products. Used for moisture determination of samples in biological experiments to ensure the accuracy and repeatability of experimental results.

In the future, halogen moisture analyzers may incorporate intelligent technology to realize automated operation and remote monitoring, improving ease of use and efficiency. More functions may be integrated, such as solubility determination, pH value determination, etc., to meet different experimental needs.

As an efficient and accurate moisture measurement equipment, the halogen moisture analyzer has the advantages of high precision, rapid measurement, easy operation, and multi-function. It is widely used in experiments and production work in the fields of chemical industry, pharmaceuticals, food, etc. By in-depth understanding of its principles, structure, usage, advantages and application scenarios, we can better apply the halogen moisture analyzer, improve experimental efficiency and product quality, and promote scientific research and industrial development.