introduction

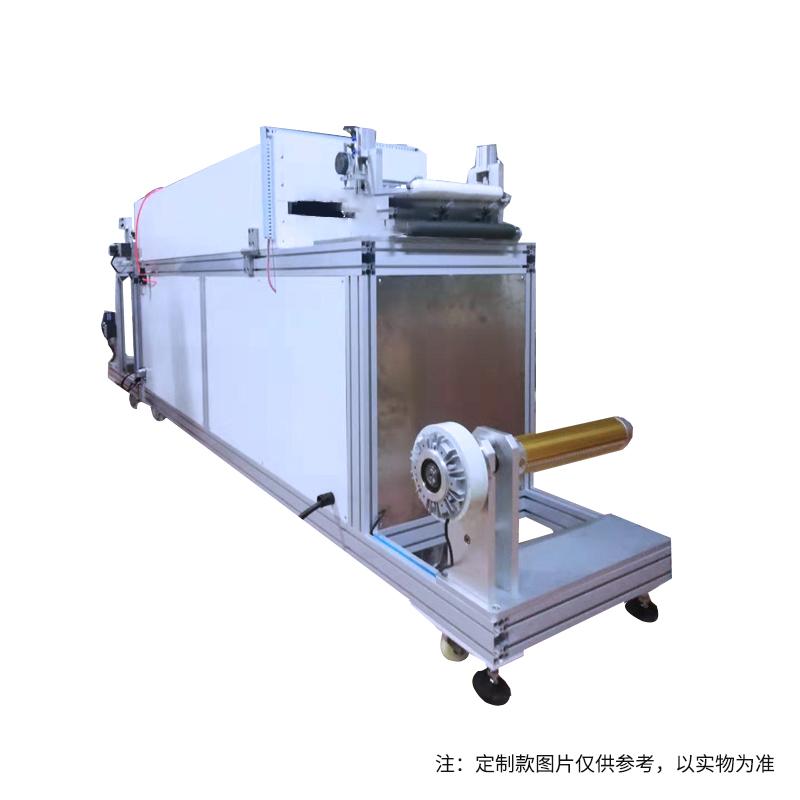

With the improvement of living standards, people's requirements for summer comfort are also increasing. Hydrogel Summer Cooling Patch is widely popular as an effective cooling product. In the production of hydrogel summer patches, the coating machine is one of the most important equipment. This article will deeply discuss the technical characteristics, selection methods and operation process of hydrogel summer patch coating machine to provide readers with a detailed understanding.

working principle

The hydrogel summer patch coating machine is mainly used to evenly coat hydrogel on the patch substrate to form the main body of the summer patch. Its working principle mainly includes the following steps:

The coating machine first receives the patch substrate to ensure a stable supply of the substrate. The base material can be paper, non-woven fabric and other materials, and its selection usually depends on the design requirements of the summer cool patch. The coating system is the core part of the coating machine, through which the hydrogel is evenly coated on the surface of the substrate. The system usually includes coating rollers, coating knives and other components, ensuring uniform distribution of hydrogel through a precise coating control system. The coated summer patch needs to be dried through a drying system to ensure that the hydrogel can firmly adhere to the surface of the substrate. Common drying methods include hot air drying, infrared drying, etc. The specific choice depends on the production process and requirements. After coating and drying, the summer sheets are precisely cut to predetermined sizes and then packaged. The precision of cutting and packaging has a significant impact on the appearance and quality of the product.

Technical features

High-precision control: The hydrogel summer patch coating machine is equipped with an advanced control system, which can achieve high-precision control of the coating process. By adjusting parameters such as coating speed and coating thickness, we ensure that each summer patch can meet the quality required by the design.

Versatility: Coating machines are usually versatile and can adapt to the production of summer sheets with different specifications and design requirements. This flexibility allows the coating machine to meet the diverse needs of the market and improves the versatility and adaptability of the equipment.

Efficient production: The coating machine has a high degree of automation, which greatly improves the efficiency of summer paste production. High-speed coating and automated control systems make the coating process faster and more stable, reducing production costs.

Quality monitoring: Advanced coating machines are usually equipped with quality monitoring systems that can monitor coating quality in real time and detect and correct possible problems in a timely manner. This helps improve the consistency and stability of production and reduces the rate of defective products.

Energy saving and environmental protection: The hydrogel summer patch coating machine usually takes energy saving and environmental protection factors into consideration during the design and manufacturing process. Use high-efficiency heating systems, exhaust gas treatment equipment, etc. to reduce energy consumption and impact on the environment.

Selection method

When choosing a hydrogel summer patch coating machine, you need to consider the following key factors:

Production scale: According to the size of the production scale, select a coating machine with corresponding capacity. Small-scale production can choose a desktop coating machine, while large-scale production may require a high-capacity, highly automated coating production line.

Summer cooling patch design requirements: Different summer cooling patch designs may require different coating machine models. For example, some summer patches require multiple layers of hydrogel or special shapes, requiring the selection of a highly adaptable coater.

Quality requirements: If you have higher quality requirements for Xia Liang Pie, you should choose a coating machine with high-precision control and quality monitoring systems.

Production process: Choose the appropriate coating machine according to the different production processes. Some special production processes may require special coating equipment, such as coating machines with infrared drying systems.

Cost considerations: Consider the balance between the cost and performance of the equipment when selecting. Choose a coater that fits your business's budget and meets your production needs.

Fully considering the above factors and choosing a hydrogel summer patch coating machine suitable for production needs can improve production efficiency, reduce costs, and ensure product quality.

How to operate

Before operation, conduct a comprehensive equipment inspection of the coating machine to ensure that all components are operating normally and that the coating system is free from clogging, leakage and other problems.

Prepare coating materials such as hydrogel to ensure the quality and stability of the coating material. Reasonably arrange material supply according to production plan.

Install the base material of the summer cool patch to ensure that the base material can run stably on the coating machine. Adjust the substrate positioning system to align it with the coating system.

According to the design requirements of Xia Liang Tie, set the coating parameters, including coating speed, coating thickness, etc. Precise adjustments are made through the control system to ensure uniform coating.

Start the coating machine and observe whether there are any abnormalities during the coating process. Adjust the operating status of the coating machine according to the actual situation to ensure the stability of coating.

After the coating is completed, send the summer cool patch to the drying system for drying. Set appropriate temperature and time parameters according to the selected drying method.

After drying, the summer sheets are precisely cut to predetermined sizes and then packaged. The process of cutting and packaging is required to ensure the appearance and quality of the product.

After the operation, clean and maintain the coating machine to ensure long-term stable operation of the equipment. Cleaning the coating system, checking the coating knife, replacing consumables, etc. are all routine maintenance tasks.

Through the above operation process, the hydrogel summer patch coating machine can achieve an efficient and stable production process, ensuring the quality and production efficiency of summer patch.

in conclusion

As the key equipment in the summer patch production line, the hydrogel summer patch coating machine has technical features such as high-precision control, multi-functionality, efficient production and quality monitoring. When selecting, factors such as production scale, design requirements, quality requirements, production process and cost need to be considered. During the operation, attention should be paid to equipment inspection, coating material preparation, substrate installation, coating parameter setting, starting the coating machine, drying, cutting and packaging, as well as cleaning and maintenance steps.

Through an in-depth understanding of the technical characteristics, selection methods and operating procedures of hydrogel summer patch coating machines, we can better guide production practices, improve the efficiency and quality of summer patch production, and meet market demand.