Plaster roll coating machines are widely used in medical, health care and other fields. This article will delve into the technical characteristics, selection principles, working process and application of plaster coil coating machines in the medical industry.

As a traditional Chinese medicine preparation, plaster has a long history of application. The emergence of modern plaster roll coating machines has brought new opportunities and challenges to plaster production. This article aims to comprehensively understand and analyze the technical characteristics of plaster roll coating machines and their applications in the medical industry.

Technical principles

The plaster roll coating machine is a mechanical equipment specially used for plaster preparation. The plaster roll coating machine adopts an advanced material handling system, which can effectively handle various plaster raw materials and ensure the stability of material quality. The machine adopts high-precision coating technology, which can achieve uniform coating of the film and ensure the quality and effect of the plaster roll. The advanced control system enables the machine to achieve automated production, improve production efficiency and reduce reliance on manual operations. Since plaster preparation involves a variety of raw materials, internal cleanliness of the equipment is crucial. Modern plaster roll applicators are equipped with efficient cleaning systems to ensure thorough cleaning between each production.

Selection principles

Choosing a suitable plaster roll coater is crucial for plaster production. The following principles need to be considered when selecting:

Choose the appropriate model according to the company's production scale to ensure that it can meet production needs while avoiding resource waste caused by excess equipment.

Different coating machines have different coating accuracy. Choose the appropriate model according to the requirements of the product to ensure the quality of the product.

Plaster roll coating machines have different degrees of automation. Choose the appropriate model according to the company's automation level and needs to improve production efficiency.

When selecting a model, you need to consider the ease of maintenance of the equipment. Choosing a model that is easy to maintain can help reduce downtime in production.

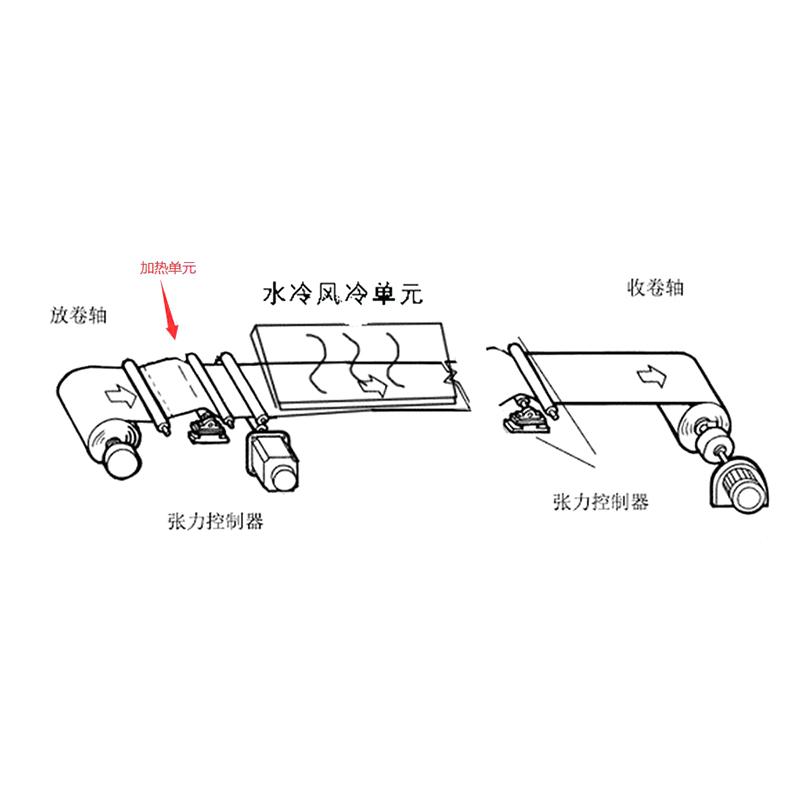

work process

The working process of the plaster roll coating machine can be divided into the following key steps:

Prepare various plaster raw materials according to the formula to ensure the quality and proportion of the materials.

The prepared plaster raw materials are fed into the material handling system of the coating machine for necessary mixing and processing to ensure the uniformity and stability of the plaster.

The processed plaster raw materials are fed into the coating system of the coating machine, and the film is evenly coated on the roll through high-precision coating technology.

After the coating is completed, the roll is cured to ensure the adhesion and stability of the plaster on the roll.

The cured plaster roll is cut and finally packaged, and the finished product is ready to leave the factory.

Plaster roll coating machines are widely used in the medical industry. Plaster roll coating machines have a high degree of automation and can achieve efficient production and meet market demand. Advanced coating technology and control systems ensure that the quality of plaster rolls is stable and meets medical standards. In addition, diversified plaster products can be produced according to different formulas and requirements to meet the diverse needs of the market.

Through a comprehensive discussion of the technical characteristics, selection principles, working process and application of the plaster roll coater in the medical industry, it can be seen that the plaster roll coater plays an important role in modern plaster production.