PUR hot melt adhesive laminating machine is a device used to compound PUR (polyurethane hot melt adhesive) with other materials. Such machines play an important role in modern industry, especially in manufacturing areas such as packaging, building materials, automobile and furniture manufacturing, etc. The correct selection of PUR hot melt adhesive laminating machine is crucial to product quality and production efficiency. This article will delve into the selection method of PUR hot melt adhesive laminating machine, covering key parameters, technical characteristics, application requirements, etc., to help companies better choose equipment suitable for their production processes.

working principle

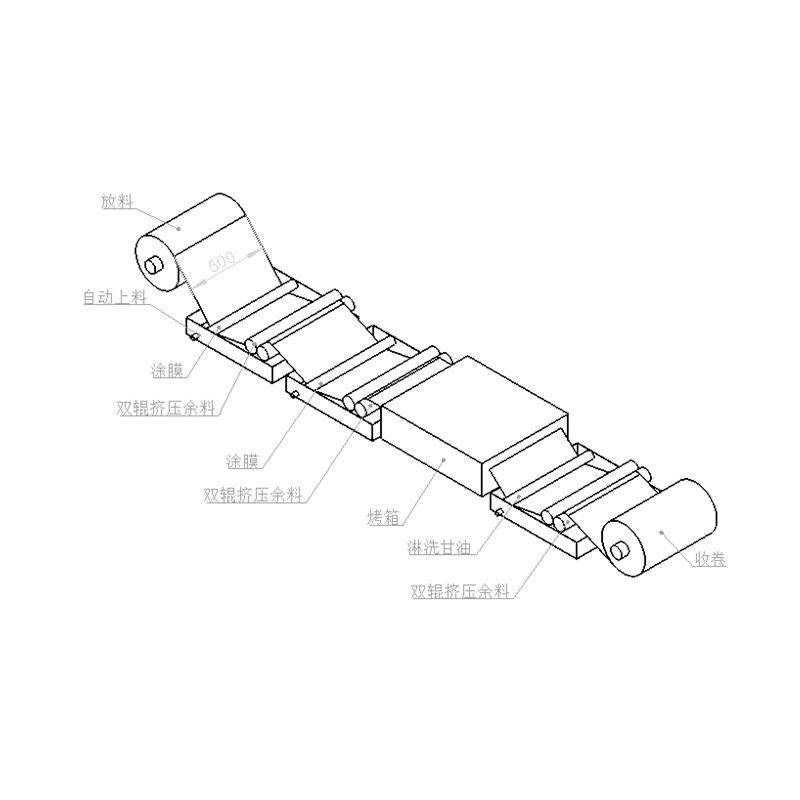

The working principle of PUR hot melt adhesive laminating machine is based on the characteristics of PUR hot melt adhesive and the application technology of melt adhesive. Typically, PUR hot melt adhesive is loaded into the machine's nozzle or nozzle in solid form and then melted through heat and pressure. Once the glue melts, it becomes a liquid and is evenly applied to the surface of the substrate to be treated through a nozzle or spray nozzle. After the coating is completed, the parts of the substrate that are in contact with the PUR hot melt adhesive are pressed together, and after a certain period of cooling and solidification, a strong composite structure is formed.

Selection method

1. Consider production needs

First, companies need to understand their production needs in detail. Including factors such as expected production scale, process flow, and production speed. Different PUR hot melt adhesive laminating machines are suitable for different production needs, so understanding the production needs is the first step in model selection.

2. Determine application areas

PUR hot melt adhesive laminating machines have different requirements in different application fields. For example, in the field of automobile manufacturing, there may be higher requirements for the bonding strength and heat resistance of PUR hot melt adhesive. In the field of packaging, more emphasis may be placed on production efficiency and rapid curing of glue. Therefore, determining the application field is crucial to selecting a suitable PUR hot melt adhesive laminating machine.

3. Pay attention to key parameters

When choosing a PUR hot melt adhesive laminating machine, there are several key parameters that require special attention:

3.1. Melting speed

Melting speed directly affects production efficiency. Machines that melt glue quickly can increase the speed of the production line, thus improving overall production efficiency. Therefore, it is necessary to select the appropriate melting speed according to production needs when selecting.

3.2. Glue quantity control accuracy

The accuracy of glue quantity control has an important impact on product quality. If the amount of glue applied is uneven, the quality of the product may be unstable. Therefore, it is crucial to choose a PUR hot melt adhesive laminating machine with high-precision glue volume control.

3.3. Temperature control system

The performance of PUR hot melt adhesive is greatly affected by temperature, so the temperature control system is a key technical feature. The advanced temperature control system ensures that the glue maintains a stable temperature throughout the production process, thereby improving the performance of the glue and the bonding effect.

3.4. Equipment stability and reliability

The stability of the production line and the reliability of the equipment are crucial to the entire production process. Choosing a PUR hot melt adhesive laminating machine with high stability and reliability can reduce the occurrence of equipment failures and improve the stability of the production line.

4. Consider future development

When selecting, companies also need to consider future development plans. Choosing a PUR hot melt adhesive laminating machine with certain scalability and upgradeability can better adapt to changes in the company's future production needs.

The correct selection of PUR hot melt adhesive laminating machine is crucial to the company's production efficiency and product quality. By in-depth understanding of production needs, application areas, key parameters and other factors, companies can make more scientific selections to ensure that the selected equipment can perfectly meet production needs. In the future, the technology of PUR hot melt adhesive laminating machines will continue to develop, and companies need to keep paying attention to new technologies to continuously improve production efficiency and product quality.