1. Background

Aluminum and aluminum alloy anodized films and organic polymer films are commonly used in a variety of applications, such as automotive parts, building materials, etc. These surface coatings may be exposed to a variety of chemicals in practical applications, so it is critical to evaluate their chemical resistance. This article will introduce a series of chemical resistance testing methods for these coatings to ensure their stability under various environmental conditions.

2. Alkali resistance test

Resting method:

Use alcohol to clean the surface of the sample, then fix the glass ring and inject a certain concentration of sodium hydroxide solution, and observe and grade after a certain period of time. First, use alcohol to clean the sample surface, then fix a glass or synthetic resin ring of a certain size on the effective surface, and inject a certain concentration of sodium hydroxide solution. After the specified time, take out the sample for cleaning, and then observe the corrosion condition on the surface of the sample and grade it.

Potentiometer method:

Conduct potentiometer testing according to standard methods to evaluate the alkali resistance of the sample under conditions of high temperature and high concentration of sodium hydroxide. Test using a potentiometer according to standard methods, the test temperature is 90°C, and the solution concentration is 200g/L. The alkali resistance of the test sample is evaluated by monitoring its potential change under conditions of high temperature and high concentration of sodium hydroxide.

3. Hydrochloric acid resistance test

Drop method:

Drop hydrochloric acid solution on the surface of the sample paint film, and observe the surface condition of the sample after 15 minutes. Drop a certain amount of hydrochloric acid solution on the surface of the paint film of the sample. After a certain period of time, take out the sample and clean it with water. Finally, observe the surface condition of the sample.

Soaking method:

Soak the sample in the hydrochloric acid test solution, take it out after soaking for a certain period of time and observe the surface condition of the sample. Soak the sample in the hydrochloric acid test solution for a certain period of time, then take it out, wash it with water and observe the surface condition of the sample.

4. Nitric acid resistance test

Resting method:

After fixing the glass ring, inject a certain concentration of nitric acid test solution, and observe and grade after a certain period of time. First use alcohol to clean the sample surface, then fix a glass or synthetic resin ring on the effective surface, and inject a certain concentration of nitric acid test solution. After the specified time, take out the sample for cleaning, and then observe the corrosion on the surface of the sample.

5. Artificial sweat resistance test

Expose the sample to artificial sweat solution, perform multiple cycles of wiping and observation, and evaluate the sweat resistance of the sample. Expose the sample to artificial sweat solution, perform multiple cycles of wiping and observation, and evaluate the sweat resistance of the sample.

6. Detergent resistance test

Place the sample in the detergent solution, soak it for a certain period of time and then take it out to observe the surface condition of the sample, and conduct an adhesive tape adhesion test at the same time. Soak the sample in the detergent solution for a certain period of time, then take it out, wash it with water and observe the surface condition of the sample, and conduct an adhesive tape adhesion test at the same time.

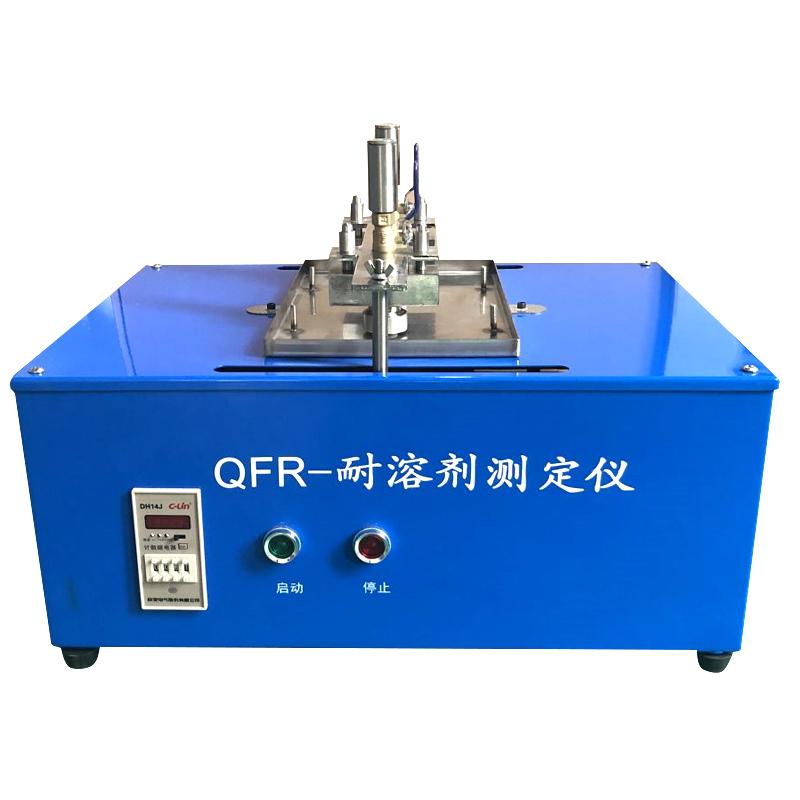

7. Solvent resistance test

Resting method:

Wet a cotton strip soaked in saturated xylene and place it on the surface of the sample to observe the softening of the sample after a certain period of time. Place a saturated xylene-soaked cotton strip on the surface of the sample for a certain period of time, take it out, wash it with water and observe the softening of the sample surface.

Wiping method:

Use gauze soaked in xylene and wipe it several times to observe the surface condition of the sample. Use gauze soaked in xylene to wipe it several times and observe the condition of the sample surface.

8. Alcohol resistance test

Place the sample in an alcohol environment and conduct multiple cycles of wiping and observation to evaluate the alcohol resistance of the sample. Expose the sample to the alcohol environment, conduct multiple cycles of wiping and observation, and evaluate the alcohol resistance of the sample.

9. Salt water resistance test

Soak the sample in the salt water solution, take it out for observation after a certain period of time, and evaluate the salt water resistance of the sample. Soak the sample in the saline solution for a certain period of time, take it out, rinse with water and observe the surface condition of the sample.

10. Mortar resistance test

The sample is exposed to the mortar environment, cleaned and observed after a certain period of time, and the mortar resistance of the sample is evaluated.

The above test methods can comprehensively evaluate the stability and durability of aluminum and aluminum alloy anodized films and organic polymer films in chemical environments, providing reliable guarantee for their practical applications.