In the printing industry, the coating quality of ink directly affects the quality of printed products. In order to ensure that the ink has good fluidity and adhesion during the printing process, the ink heating coater came into being. This article will delve into the working principle, application scope and future development direction of ink heating coating machines.

working principle

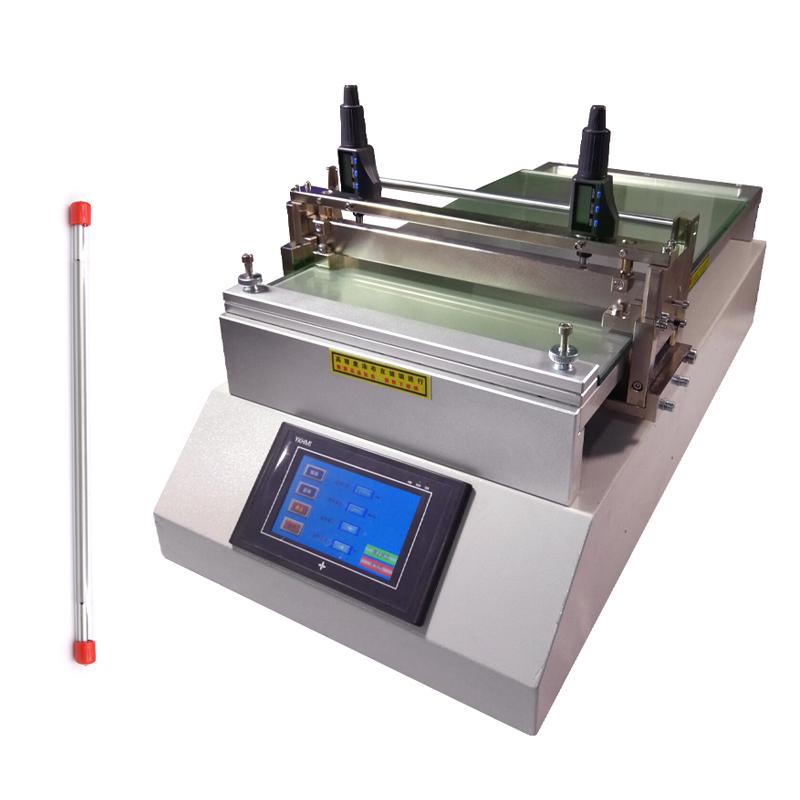

The ink heating coater is a device used to evenly coat ink on the surface of printing materials. The solid ink is heated to a certain temperature through a heating device, turning it into a liquid state to improve the fluidity and coating performance of the ink. The heated liquid ink is evenly coated on the surface of the printing material through the coating system, including coating rollers, scrapers, pressure rollers and other components. By controlling the temperature of the heating device and the pressure of the coating system, it is ensured that the ink maintains constant temperature and pressure during the coating process, thereby improving coating quality and stability. The ink coated on the surface of the printing material is quickly cured through a drying device to ensure that the ink will not smudge or shift during the printing process.

Application scope

Ink heating coaters are widely used in the printing industry. Ink heating coaters that can be used in offset printing machines can ensure that the ink has good fluidity and adhesion during high-speed printing, improving the quality and production efficiency of printed matter. . The ink heating coating machine used in flexographic printing machines can effectively solve the problems of poor ink fluidity and slow drying speed in flexographic printing, and improve the printing quality and color stability of printed matter. The ink heating coater for gravure printing can improve the ink coating uniformity and glossiness of gravure printing, and is suitable for high-demand packaging printing and commercial printing. The ink heating coater for digital printing machines can improve the color fullness and image clarity of digital printing, and is suitable for personalized printing and short-run printing.

With the continuous advancement of science and technology and the changing market demand, ink heating coating machines have development potential in the following aspects. In the future, the ink heating coating machine will be more intelligent, equipped with automatic control and data collection functions, and realize intelligent control and remote monitoring. In the future, ink heating coating machines will pay more attention to energy conservation and environmental protection, using energy-saving technology and environmentally friendly materials to reduce energy consumption and environmental pollution. In the future, heated ink coating machines will pay more attention to multi-functionality. They can not only be used for heated coating of ink, but also for glue coating, lamination and other processes.

Conclusion

As an important equipment in the printing industry, the ink heating coater is of great significance for improving printing quality and optimizing the production process. By heating the coater, the ink can maintain constant temperature and pressure during the printing process, ensuring that the printed matter has good color stability and printing effects. In the future, with the continuous development of science and technology and the changing market demand, ink heating coating machines will be more intelligent, energy-saving, environmentally friendly, multi-functional, efficient and stable, providing more advanced and convenient solutions for the development of the printing industry. .