introduction

In modern scientific research and industrial production, surface coating technology plays a vital role. As a special surface treatment material, light diffusion film has a wide range of applications in the fields of optics, optoelectronics, display technology and other fields. As a key tool, the laboratory-specific coating machine provides an efficient and precise means for the preparation of light diffusion films. This article will discuss the application of laboratory-specific coating machines in the preparation of light diffusion films, and conduct an in-depth analysis of their performance, process parameters, etc.

Characteristics and applications of light diffusion films

Light diffusion film is a thin film material that can evenly scatter incident light. By regulating its surface microstructure and material optical properties, precise control of light can be achieved, giving it a soft and uniform scattering effect. Light diffusion films are widely used in LED lighting, display devices, solar cells and other fields, and can improve the optical performance and visual effects of equipment.

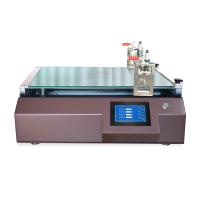

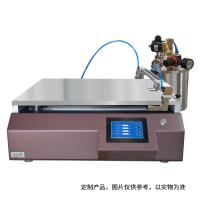

Working principle of laboratory special coating machine

The laboratory special coater is a special equipment used for film coating. Its working principle is based on the control and adjustment of the coating process. It mainly includes coating heads, feeding systems, substrate support systems, drying devices and other components. The coating head evenly coats the solution or slurry on the substrate surface by accurately controlling the coating thickness and speed. The feeding system is responsible for providing solution or slurry supply and controlling the coating speed and flow rate. The substrate support system is used to fix and support the substrate to be coated to ensure the stability of the substrate during the coating process. The drying device is used to quickly dry the liquid coated on the surface of the substrate to form a uniform thin film structure.

Application of laboratory-specific coating machine in the preparation of light diffusion film

1. Optimization of coating process parameters

The laboratory-specific coating machine can accurately control coating thickness, speed, temperature and other parameters. By optimizing these parameters, precise control of the microstructure of the light diffusion film can be achieved. For example, adjusting the coating speed and pressure can change the surface roughness and pore structure of the light diffusion film, thus affecting its optical properties.

2. Material selection and formula optimization

The use of a coating machine makes the coating of different materials more convenient and faster. Different material formulas and proportions can be tried to obtain a light diffusion film with specific optical properties. By conducting trial coatings on the coating machine, the optimal formula can be quickly screened and the efficiency and cost of material use can be further optimized.

3. Mass production and rapid testing

The laboratory-specific coating machine is efficient and automated, can achieve mass production of light diffusion films, and has high repeatability and stability. At the same time, the use of the coating machine can also quickly conduct small-scale experiments and quickly evaluate the impact of different process parameters on the performance of the light diffusion film, providing a reference and basis for further research.

Development trends and challenges of laboratory-specific coating machines

With the wide application of light diffusion films in the fields of optics and optoelectronics, the development of laboratory-specific coating machines has also presented some new trends and challenges. These include:

Demand for high-performance coating machines: With the continuous improvement of performance requirements for light diffusion films, higher requirements are also put forward for the performance and precision of coating machines. In the future, coating machines will move towards higher speed, higher precision, More functional aspects are developed.

Development of multi-functional integrated equipment: In order to meet the demand for light diffusion films in different fields, future coating machines may develop in the direction of multi-functional integration, enabling the integration and automation of multiple coating processes.

Environmental protection and energy consumption: The coating process involves environmental issues such as the use of solvents and waste liquid treatment. In the future, coating machines will pay more attention to energy conservation, emission reduction and the development of environmentally friendly technologies to achieve a more sustainable production model.

in conclusion

As a key equipment for the preparation of light diffusion films, laboratory-specific coating machines have important applications and development prospects in the fields of optics, optoelectronics and other fields. By accurately controlling the coating process parameters and material formula, the coating machine can achieve precise control of the performance of the light diffusion film, providing important support for research and applications in related fields.