Summary:

As a commonly used thermal insulation material, thermal insulation sheets are widely used in automobiles, construction, electronics and other fields. In order to improve the performance and durability of thermal insulation sheets, it is often necessary to coat the surface with a thin film to achieve enhanced thermal insulation, waterproof and dustproof functions. Based on a small automatic film scraping machine, this article conducts an experimental study on coating films on heat insulation sheets, discusses the impact of coating process parameters on the coating effect, and evaluates and analyzes the performance of the film coating machine.

I. Introduction

Thermal insulation sheet is a material with thermal insulation properties. It is often used in automobile engine compartments, building exterior walls, electronic equipment and other fields to reduce energy transmission and protect equipment. However, in order to improve the performance and service life of thermal insulation sheets, it is often necessary to coat the surface with a thin film to achieve enhanced thermal insulation effect, waterproof and dustproof functions. As a convenient and efficient coating equipment, the small automatic film scraping machine has the potential and application value of coating films on heat insulation sheets.

2. Experimental design

Experimental materials: Select common insulation sheet materials, such as polystyrene foam board (EPS), polyurethane foam board, etc. as experimental samples, and select commonly used coating materials, such as polyethylene, polyurethane, etc. as coating materials.

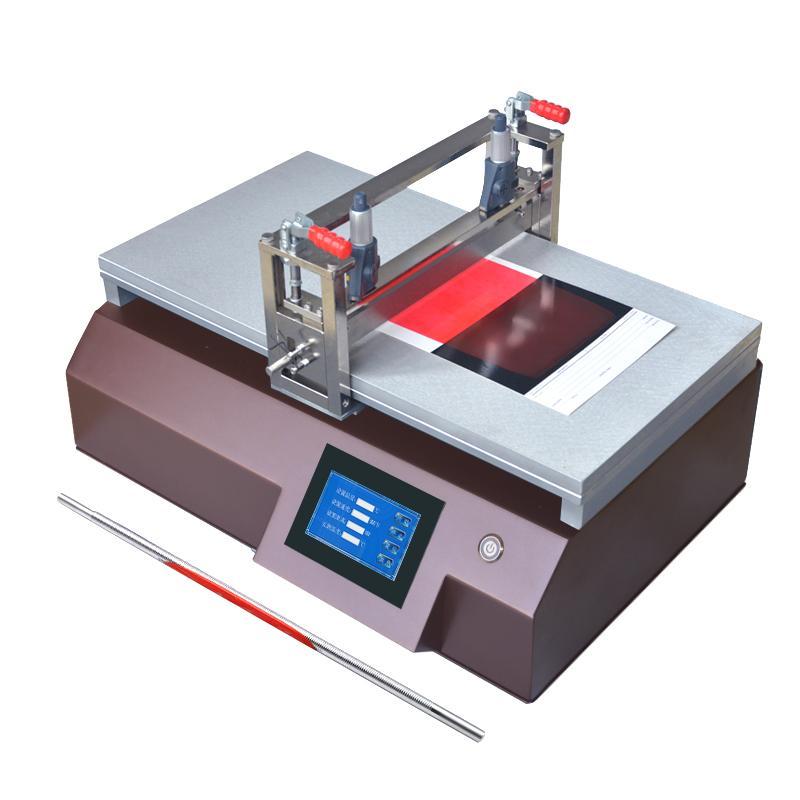

Experimental device: A small automatic film scraping machine is selected as the coating equipment, equipped with a coating system, a scraper system, a drying system, etc., to realize the coating treatment of the heat insulation sheet.

Experimental steps:

Cut the insulation sheet to the desired size and clean the surface to remove impurities.

According to the experimental requirements, set the coating speed, scraper pressure, coating thickness and other parameters of the coating machine.

Place the heat insulation sheet on the coating machine, start the coating machine to conduct a coating experiment, and record the parameters and results during the coating process.

According to the coating effect and experimental data, the influence of coating process parameters on the coating effect is analyzed, and the performance and stability of the coating machine are evaluated.

3. Experimental results and analysis

After coating experiments, a thin film layer was obtained that was evenly coated on the surface of the heat insulation sheet. The film thickness and uniformity were good, and the coating effect was in line with expectations. Experimental results show that parameters such as coating speed, scraper pressure and coating thickness have a significant impact on the coating effect. Reasonable setting of coating parameters can achieve better coating effects. The small automatic film scraping machine has the advantages of high film coating accuracy, easy operation, and high production efficiency. It is suitable for film coating treatment of materials such as heat insulation sheets.

4. Conclusion and outlook

Based on a small automatic film scraping machine, this article conducts an experimental study on coating films on heat insulation sheets, discusses the impact of coating process parameters on the coating effect, and evaluates and analyzes the performance of the film coating machine. The experimental results show that the small automatic film scraping machine has the potential and application value of coating films on heat insulation sheets, and can realize the automation and efficiency of the coating process. In the future, the coating process parameters can be further optimized, the performance and stability of the coating machine can be improved, and its application in the coating field of materials such as heat insulation sheets can be expanded.