With the continuous development of science and technology, automation technology has been widely used in various industries. Among them, automatic coating machines, as an important automation equipment, have been widely used in various fields, including but not limited to automobile manufacturing and building materials. production, furniture manufacturing, etc. In these applications, the role of the automatic coating machine is to evenly coat coatings on various substrates to improve product quality and production efficiency. In the production process of light-shielding films, automatic coating machines also play a vital role.

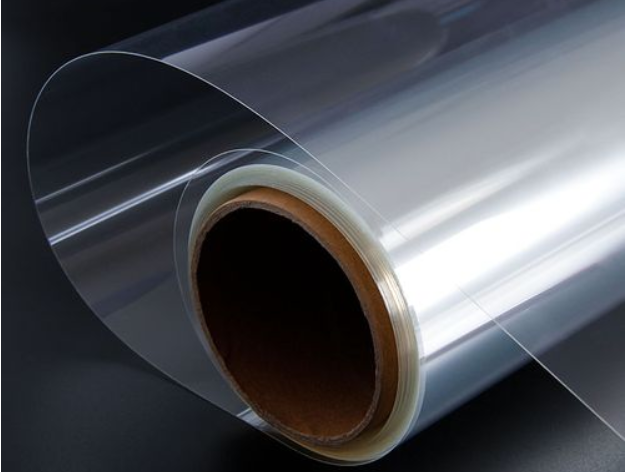

Light-shielding film is a functional film material widely used in construction, automobiles and other fields. It can effectively block direct sunlight, block light and reduce indoor temperature. Since light-shielding films usually need to have certain aesthetics, durability and optical properties, their production process has high requirements on the coating process. The application of automatic coating machines in the production of light-shielding films can not only improve the accuracy and stability of coating, but also greatly improve production efficiency and reduce production costs.

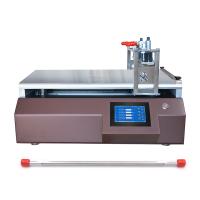

First of all, the automatic coating machine can realize automatic control of the coating process, thus improving the accuracy and stability of coating. In the traditional manual coating process, the operator's technical level and experience have a great impact on the coating quality, and it is difficult to ensure that every coating can achieve the same effect. The automatic coating machine can accurately control the coating thickness, speed and coating method through a precise control system, thereby ensuring that each piece of light-shielding film has the same coating quality and performance. This not only improves product consistency, but also reduces the scrap rate in production and improves production efficiency.

Secondly, the application of automatic coating machines can greatly improve production efficiency. The traditional manual coating process requires a lot of manpower and time, and the production efficiency is low, making it difficult to meet the needs of mass production. The automatic coating machine can realize the automation of the coating process, greatly reducing the time and labor intensity of manual operation, thus improving production efficiency. Moreover, automatic coating machines usually have high coating speed and work efficiency, and can quickly complete large-volume coating tasks to meet market demand.

In addition, the automatic coating machine can also realize intelligent management of the coating process in the production of light-shielding films. Modern automatic coating machines are usually equipped with reliable control systems and sensors that can monitor various parameters during the coating process in real time and make intelligent adjustments based on actual conditions to ensure coating quality and stability. Moreover, some automatic coating machines also have remote monitoring and remote control functions, which can realize remote monitoring and management of the coating process, improving the convenience and efficiency of production management.

In general, the application of automatic coating machines in the production of light-shielding films is of great significance and has broad market prospects. Through automated control, improved production efficiency and intelligent management, automatic coating machines can bring huge changes and improvements to the production of light-shielding films, pushing the entire industry to develop in a more efficient, intelligent and sustainable direction. It is believed that with the continuous advancement of technology and the continuous improvement of automatic coating machines, its application in the production of light-shielding films will be further promoted and popularized, making greater contributions to the development and progress of the industry.