Abstract: Photolithography technology is one of the key steps in the microelectronics process, and in the photolithography process, the preparation of photoresist films is crucial. As an efficient and accurate film preparation equipment, the experimental automatic film coating machine plays an important role in the photoresist film preparation process. This article will discuss the application of experimental automatic coating machines in the preparation of photoresist films, including its principles, operating methods, advantages, and practical applications in scientific research laboratories.

introduction:

Photolithography technology is one of the key technologies in the microelectronics manufacturing process and is widely used in integrated circuits, optical devices, MEMS and other fields. In the photolithography process, the preparation of photoresist film is a crucial step, and its quality directly affects subsequent pattern transfer and device performance. As an efficient and accurate film preparation equipment, the experimental automatic film coating machine plays an important role in the preparation of photoresist films. This article will discuss the principles, operating methods, advantages and practical applications of experimental automatic film coating machines in scientific research laboratories.

1. Principle and working method of experimental automatic film coating machine

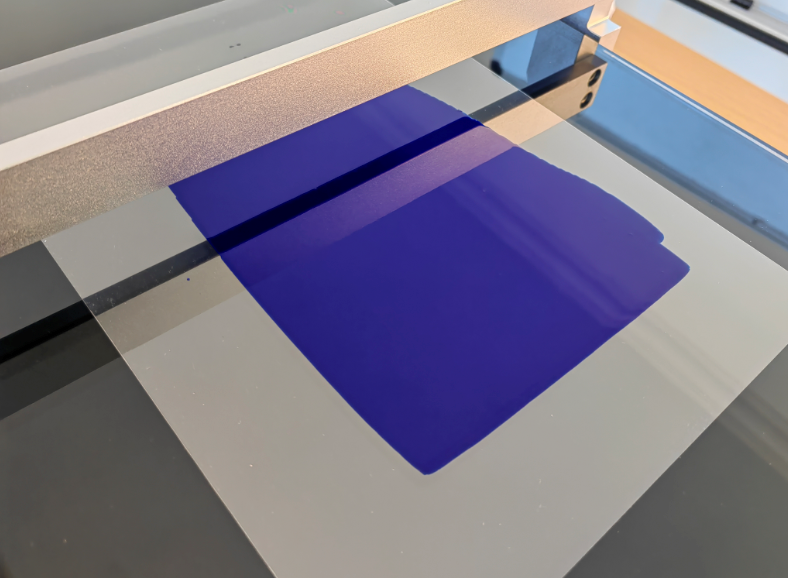

The experimental automatic film coating machine is an automated equipment for coating films. Its working principle is based on the movement of the coating scraper and a precise control system. Usually, an automatic film coating machine consists of a coating module, a scraper module, a bracket, a control system, etc. During the working process, the photoresist solution or coating is first evenly coated on the surface of the silicon wafer or other substrate, and then scraped flat with a scraper to form a uniform thin layer on the surface of the substrate.

The working method of the experimental automatic coating machine is usually divided into several steps: first, the coating parameters are set, including coating speed, scraper pressure, substrate rotation speed, etc.; then the photoresist solution or coating is injected into the coating module , apply it evenly on the surface of the substrate through the coating device; finally, start the scraper module, move the scraper along the surface of the substrate, and scrape off the excess photoresist to form a uniform film.

2. Application of experimental automatic coating machine in photoresist film preparation

1. Precisely control coating thickness

The coating thickness of the photoresist film is one of the important factors affecting the quality of the photolithography process and device performance. The experimental automatic coating machine is equipped with a coating thickness control system, which can accurately control the coating thickness and achieve nanometer-level or even higher-precision coating. By adjusting the coating parameters and squeegee pressure, photoresist films of different thicknesses can be prepared to meet different process requirements.

2. Improve coating efficiency

The traditional manual coating method has problems such as uneven coating and low production efficiency. The experimental automatic coating machine has an automated coating function that can greatly improve coating efficiency. Through the automated control system, a continuous and stable coating process can be achieved, reducing manual intervention, improving production efficiency, and reducing production costs.

3. Improve film quality

The quality of the photoresist film directly affects the subsequent photolithography pattern quality and device performance. The experimental automatic film coating machine adopts a precise coating control system and scraper module, which can achieve uniform coating and smooth surface of the photoresist film, reduce surface defects such as bubbles and scratches, and improve film quality and the stability of the photolithography process. .

4. Diversified coating materials

The preparation of photoresist films requires the use of different types of photoresist solutions or coatings, such as positive glue, negative glue, photochromic glue, etc. The experimental automatic coating machine has diversified coating modules and coating parameter settings, which can adapt to the coating needs of different types of photoresists and meet the requirements of different process flows.

3. Practical application of experimental automatic film coating machines in scientific research laboratories

As an efficient and accurate film preparation equipment, the experimental automatic film coating machine is widely used in scientific research laboratories. Mainly reflected in the following aspects:

Microelectronic device research

In the preparation process of microelectronic devices, the preparation of photoresist films is an important step. The experimental automatic coating machine can achieve precise coating and thickness control of photoresist films, providing a reliable experimental platform for the research and development of microelectronic devices.

Optical device research

The preparation of optical devices also requires the use of photoresist films, such as gratings, microlens arrays, etc. The experimental automatic coating machine can achieve uniform coating and thickness control of photoresist films, providing important technical support for the research and preparation of optical devices.

MEMS device research

In the preparation process of microelectromechanical systems (MEMS) devices, the preparation of photoresist films is also a key step. The experimental automatic coating machine can achieve precise coating and thickness control of photoresist films, providing important technical support for the research and development of MEMS devices.

Conclusion

As an efficient and accurate film preparation equipment, the experimental automatic film coating machine has important application value in the preparation of photoresist films. By accurately controlling the coating parameters and the squeegee module, uniform coating, thickness control and quality improvement of the photoresist film can be achieved, providing important technical support and experimental platform for research and development in the fields of microelectronics, optics, MEMS and other fields. . With the continuous development and innovation of science and technology, it is believed that the application of experimental automatic coating machines in the field of photoresist film preparation will be further expanded and deepened.