It is known from the ISO 21760-1 standard that when preparing unsupported adhesive films, there are three different coating methods to ensure even coating of the film and the required thickness. Here are three commonly used methods:

spin coating

Spin coating is a very useful coating method, especially for coating only one side of the film. Spin coating is typically used for small or medium-sized films that are flat and symmetrically shaped. Typical coating thickness ranges from 200 nanometers to 25 microns.

The basic equipment for spin coating includes a rotating device, coating delivery device, collection tank/liquid storage tank, pump and filter element.

Operating procedures

1. Coating thickness: Coating thickness depends on the solid content, solvent composition, temperature and viscosity of the coating material. In spin coating applications, it is often effective to use the solids content (or viscosity and spin rate) of the coating material to adjust the coating thickness while holding other coating characteristics and environmental factors constant.

2. Application of liquid solution: Apply the liquid solution to the substrate under slow rotation or stationary sample state.

3. Sample rotation: Rotate the sample at a slow speed to distribute the solution.

4. Increase the rotation speed: Increase the rotation speed to achieve the desired thickness.

5. Keep spinning: Keep the substrate spinning while the solvent evaporates.

The spin coating method provides an efficient coating technique, particularly suitable for films that require single-sided coating. By controlling parameters such as the solid content, solvent composition, and rotation rate of the coating material, precise control of the coating thickness can be achieved to ensure the stability of coating quality and performance.

Blade coating

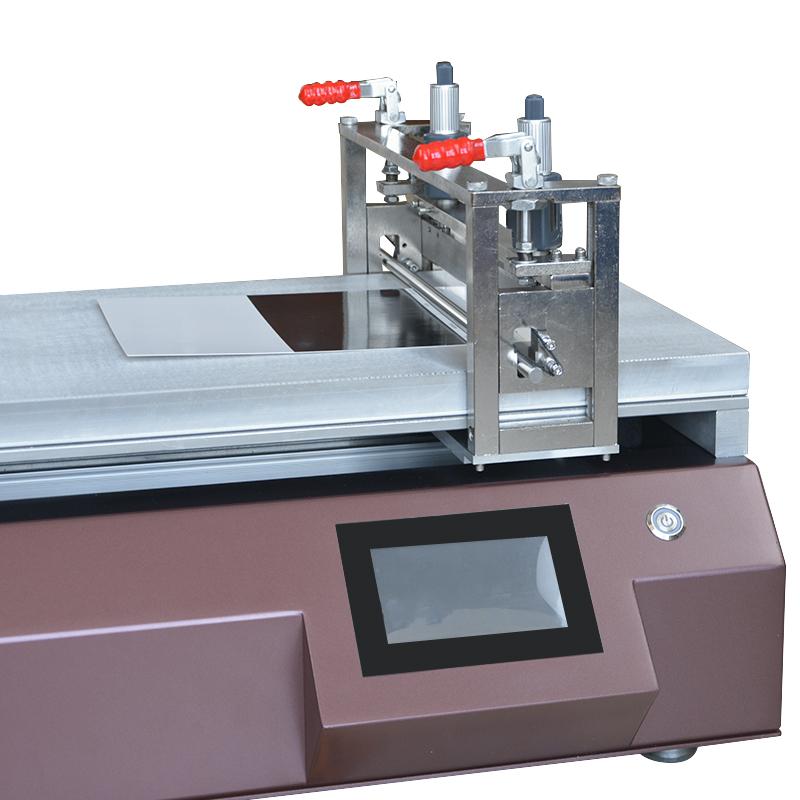

Blade coating, also known as knife coating or blade coating, is a processing method for preparing large-area thin films on rigid or flexible substrates. Its thickness is mainly controlled by the size of the gap between the scraper and the surface. In laboratory-scale processing, the scraper moves over a flat surface. In large-scale roll-to-roll processes, the scraper is fixed to the moving surface.

Laboratory blade coating equipment includes blade applicators, automatic coaters and waste chutes.

Operating procedures

1. Laying of the substrate film: Lay the substrate film as flat as possible on the glass bed of the pusher.

2. Placement of the applicator: Place the Film Applicator on the substrate film.

3. Adjust the threaded screws of the applicator: Adjust the two micron screws on the applicator to control the gap between the scraper and the substrate surface.

4. Pour the coating solution: Pour the coating solution onto the substrate.

5. Set coating speed: Set the coating speed before running the pusher.

6. Push the coater: The pusher pushes the coater so that the coating solution is distributed on the substrate surface with a constant thickness.

Through the blade coating method, the film can be evenly coated on the substrate, thereby realizing the preparation of large-area films.

Spray coating

Spray coating is a method widely used for car body painting and for graffiti artists using spray cans. Functional liquid or ink is atomized at the nozzle of the printhead, creating a continuous stream of droplets. Spray coating is also used to apply organic coatings to electronic parts. Spraying includes the commonly used compressed air evaporation method, as well as pressureless spraying, thermal spraying, electronic spraying, dry powder resin spraying, and even common aerosol can spraying. Typical coating thickness ranges from 5 microns to 200 microns.

The basic equipment for spray coating includes coating ink supply, gas supply and nozzles.

Operating procedures

1. Preparation of coating polymer solution: Place the coating polymer solution into the coating ink supply connected to the nozzle.

2. Controlled pressure of compressed nitrogen: Add controlled-pressure compressed nitrogen into the air focusing cover. The width and shape of the spray coating beam is controlled by gas flow and hood position.

3. Motion control of the nozzle: Use the xyz platform to control the movement of the nozzle. Keep the distance between the two nozzle paths constant (2mm) and less than the spray width (4mm).

With the spray coating method, the coating can be evenly spread on the substrate to achieve the desired coating thickness.