introduction

In the field of modern science and technology, optical devices are developing rapidly. In order to improve their performance and efficiency, the preparation of refractive index matching films has become crucial. This film can make the transmission of light on the device surface more efficient, reduce reflection and loss, thereby improving the performance of the entire system. In the preparation process of refractive index matching films, automatic coating machines play a vital role. This article will delve into the application and significance of automatic coating machines in the preparation of refractive index matching films.

1. The importance of refractive index matching films

Index matching films play a vital role in optical devices. Its main functions include:

Reduce reflection losses: Reflection occurs when light passes from one medium into another medium with a higher or lower refractive index. By using refractive index matching films, this reflection can be reduced and light transmission efficiency improved.

Improve the performance of optical devices: Optical devices such as laser devices, solar cells, etc. require accurate transmission of light during their working process, and refractive index matching films can help achieve this goal, thereby improving the performance of the device.

Enhance the stability and durability of optical devices: Refractive index matching films can reduce reflections on the surface of optical devices and prevent surface damage, thereby improving the stability and durability of the device.

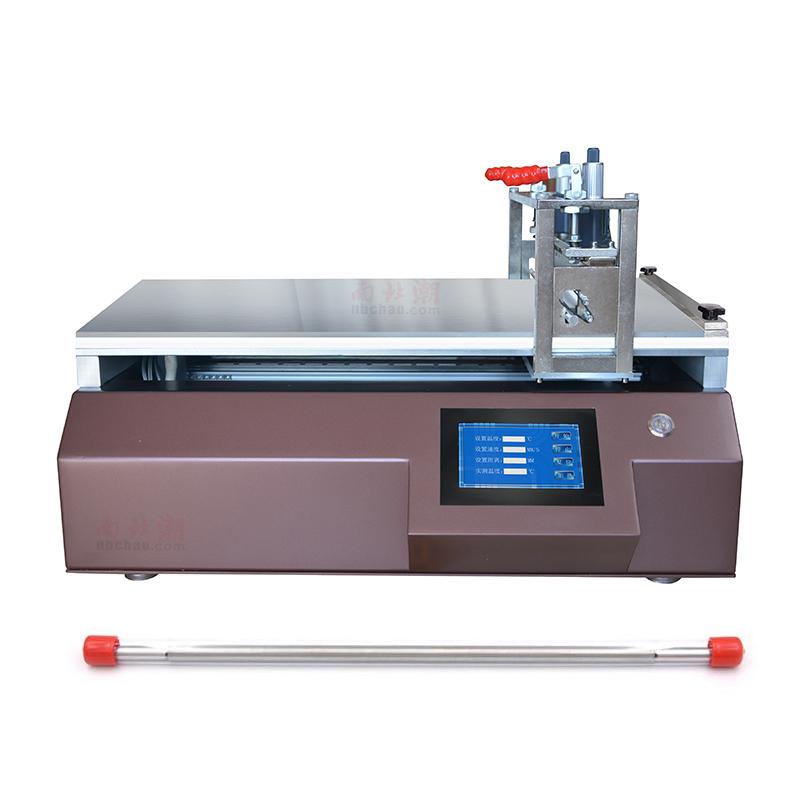

2. Function and characteristics of automatic coating machine

As an advanced coating equipment, the automatic coating machine has the following characteristics:

High efficiency: The automatic coating machine can achieve continuous production, greatly improving production efficiency.

Precise control: Through a precise control system, the automatic coating machine can achieve precise control of coating thickness, speed, temperature and other parameters to ensure that the prepared film has consistent thickness and quality.

Diversified coating technologies: Automatic coating machines can use a variety of coating technologies, including spin coating, spray coating, sputtering, etc., to meet the needs of different materials and applications.

Reduce human errors: The use of automatic coating machines can reduce human errors and improve the accuracy and consistency of film preparation.

3. Application of automatic coating machine in the preparation of refractive index matching films

In the preparation process of refractive index matching films, automatic coating machines play an important role:

Precise coating control: The automatic coating machine can achieve precise control of the film coating process, including the adjustment of coating thickness, speed, temperature and other parameters, thereby ensuring that the prepared film has consistent thickness and quality.

Efficient production capacity: The automatic coating machine can achieve continuous production, greatly improving the production capacity of film preparation and meeting the needs of large-scale production.

Application of multiple coating technologies: Automatic coating machines can use a variety of coating technologies to select appropriate coating methods according to the needs of different materials and applications, thereby optimizing film performance.

Reduce production costs: The use of automatic coating machines can reduce labor costs and energy consumption, improve production efficiency, thereby reducing the production costs of film preparation.

4. Application cases

Automatic coating machines have been widely used in the preparation of refractive index matching films, such as:

Optical fiber manufacturing: As an important part of modern communications, optical fiber requires low-loss optical properties. Automatic coating machines can be used to prepare refractive index matching films to improve the transmission efficiency and performance of optical fibers.

Laser device preparation: Laser devices need to achieve efficient light transmission during operation, and the preparation of refractive index matching films can help achieve this goal. The automatic coating machine can provide an efficient and precise coating process to ensure the performance and stability of the laser device.

Solar cell production: Solar cells need to maximize the absorption of light energy rather than reflect it. The preparation of refractive index matching films can reduce light reflection and improve the conversion efficiency of solar cells. Automatic coating machines can achieve precise control of the thin film coating process, thereby improving the performance and stability of solar cells.

5 Conclusion

Automatic coaters play an important role in refractive index matching film preparation by providing an efficient and precise coating process to ensure that the prepared films have consistent thickness and quality. As the application fields of optical devices continue to expand, automatic coating machines will continue to play an important role in promoting the advancement of refractive index matching film preparation technology and providing strong support for the performance improvement and application expansion of optical devices.