Accurate measurement of the viscosity of plastic materials is crucial in industrial production and quality control. GB/T32683 specifies the method for measuring the viscosity of emulsified or suspended liquid polymers or resins using a falling ball viscometer. This article will introduce in detail how to use a falling ball viscometer to measure the viscosity of plastics, including measurement range, principle, instrument, operating steps, etc.

1 Scope

According to GB/T32683, the liquid measured using a falling ball viscometer should have Newtonian fluid characteristics, a viscosity range of 0.6 mPa·s~250,000 mPa·s, and a measurement temperature range of -20°C to +120°C. If the fluid behavior is different from Newtonian fluid behavior, different forms of viscometer can be selected for measurement.

2. Principle

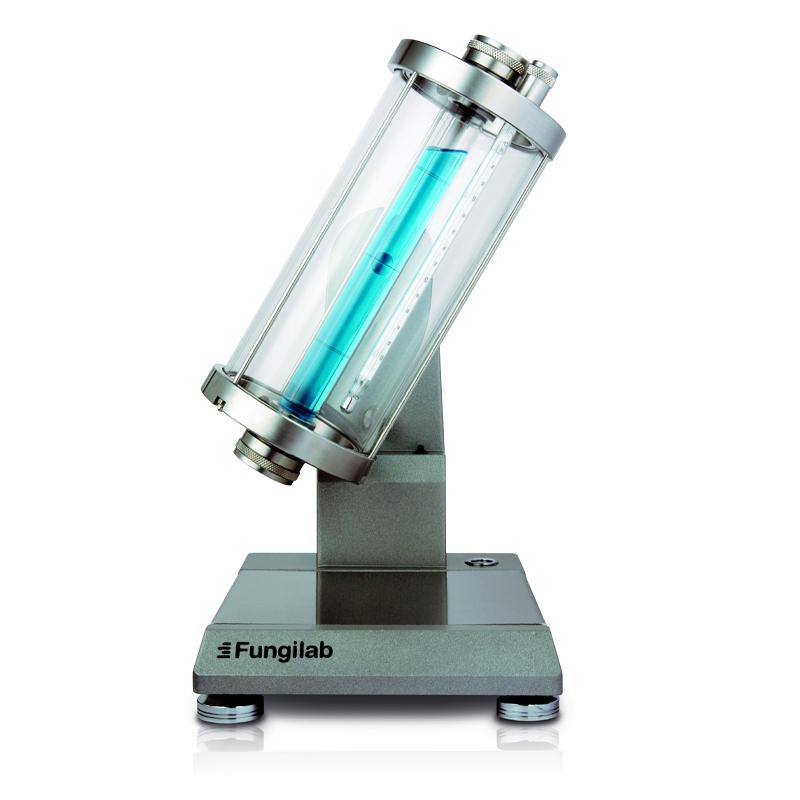

The principle of the falling ball viscometer is to measure the viscosity of a liquid by observing the movement time of a solid ball in an inclined cylindrical tube filled with liquid. The viscosity is calculated by measuring the time between the ball passing two marks.

3. Instruments

The falling ball viscometer consists of a measuring tube and 6 falling balls. The measuring tubes are made of borosilicate glass and the diameter of the falling balls varies from 11.0 mm to 15.81 mm. The measuring tube and ball should be free of defects. The instrument is equipped with a thermostat to ensure a constant temperature of the liquid during measurement.

4. Operation steps

Make sure the instrument is clean and dry and use a suitable solvent to clean the measuring tube.

Add the liquid to be measured into the measuring tube and put in the falling ball. Make sure there are no bubbles in the dropped ball.

Install the stopper with capillary tube on the upper end of the measuring tube and tighten it.

Let the falling ball roll once along the length of the measuring tube to thoroughly mix the liquid.

At the specified temperature, wait at least 15 minutes for equilibrium time. If the liquid viscosity is high or the temperature difference is large, the equilibrium time should be extended appropriately.

Start measuring and record the time between the ball passing the two marks.

Each sample was measured in duplicate at least three times to ensure accuracy.

5. Precautions

Density measurement should be carried out according to the requirements of GB/T 6750-2007 before measurement.

The instrument should be calibrated before use, and recalibration is also required when new measuring tubes or dropped balls are used.

Avoid the thermometer being affected by thermal radiation to ensure accurate temperature measurement.

Make sure the drop ball, measuring tube and other parts are clean to avoid affecting the measurement results.

Keep the experimental environment stable during the measurement, especially the liquid temperature and instrument level.

Using a falling ball viscometer is a reliable method of measuring the viscosity of plastic materials. By operating the instrument correctly and following standard operating procedures, accurate and reliable measurement results can be obtained, thereby ensuring product quality and production efficiency.