Floor coatings are widely used in construction, transportation, industry and other fields, and their quality directly affects the aesthetics, durability and safety of the ground. The viscosity of floor coatings is one of the important parameters for evaluating its fluidity and coating performance. In order to accurately evaluate the viscosity of floor coatings and improve the quality of floor coatings, floor coating viscosity measuring instruments came into being. This article will introduce the working principle, application and important role of floor coating viscosity measuring instrument in the floor coating industry.

working principle

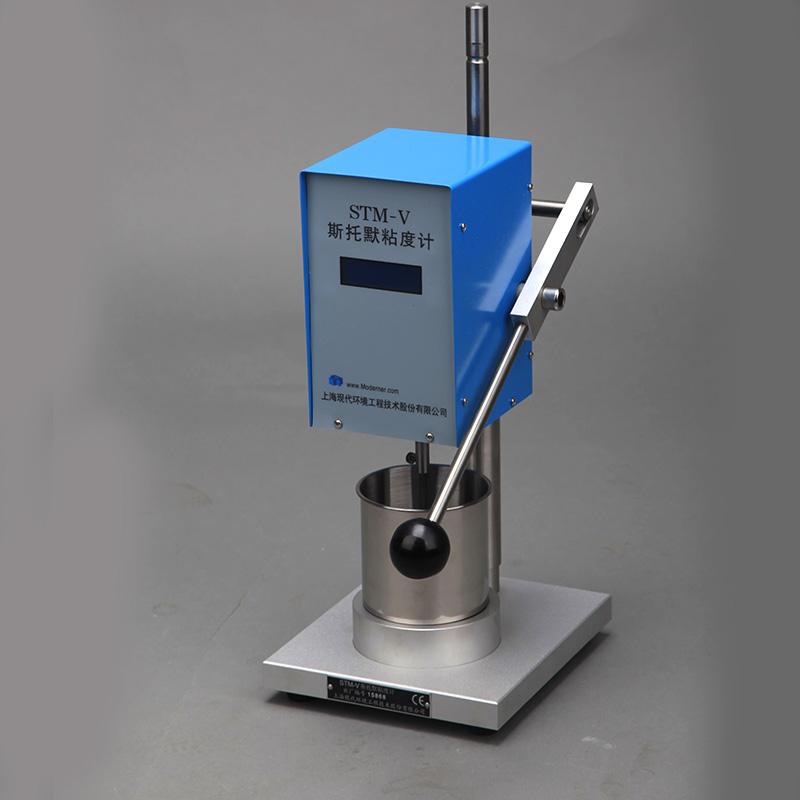

The floor coating viscosity measuring instrument mainly measures the fluidity of the floor coating at a certain temperature through a rotating cup viscometer or a Flow Cup viscometer. The floor coating viscosity measuring instrument uses a rotating cup or Flow Cup viscometer for measurement. The viscosity value of the floor coating is calculated by the rotational speed or flow rate of the rotating or Flow Cup viscometer, and the flow resistance of the paint in the cup. The floor coating viscosity measuring instrument is equipped with a temperature control system to ensure that the viscosity of the floor coating is measured at a certain temperature. Because the viscosity of floor coatings changes with temperature, temperature control is critical to the accuracy of viscosity measurements. The floor coating viscosity measuring instrument displays the viscosity measurement results in real time through the built-in display screen or the interface connected to the computer, and can record the measurement data for subsequent analysis and reference.

Application scope

Floor coating viscosity measuring instruments are widely used in the floor coating industry to measure and evaluate the viscosity of floor coatings to ensure stable quality of floor coatings and meet customer requirements. According to the viscosity measurement results, the production process parameters are adjusted, the floor coating formula is optimized, and the fluidity and coating performance of the coating are improved. By measuring and comparing the viscosity of different materials, you can select the appropriate floor coating to improve the applicability and durability of the floor coating. Conduct viscosity measurements of new materials and new processes to guide the development and promotion of new products.

As an important testing equipment, the floor coating viscosity measuring instrument plays a key role in the floor coating industry. Through viscosity measurement and evaluation, we ensure the stable quality of floor coatings and improve the service life and durability of the product. According to the viscosity measurement results, the production process parameters are adjusted, the process flow is optimized, and the production efficiency and product quality are improved. Through process improvement and product quality control, production costs are reduced and the economic benefits of products are improved.

Conclusion

As an important testing equipment, the floor coating viscosity measuring instrument plays an important role in the floor coating industry. By evaluating the viscosity of floor coatings, we improve product quality, optimize process flow, reduce production costs, and enhance brand competitiveness, providing strong support for the sustainable development of the industry. Therefore, the floor coating viscosity measuring instrument has broad application prospects in the floor coating industry and deserves further promotion and application.