In order to measure the porosity of the coating film on the metal, we proposed a simple instrument as early as 1931. This instrument is composed of a milliampmeter, a power supply, and a glass tube (a sponge is inserted into the thick end of the tube). (Related instrument: conductivity meter)

The sponge is connected to the negative pole of the power supply; and the tested metal object is connected to the positive pole through the milliampmeter. The sponge wetted with a weak solution of electrolyte conducts electricity on the surface of the paint film, and the presence of porosity is determined by the reading of a milliampmeter.

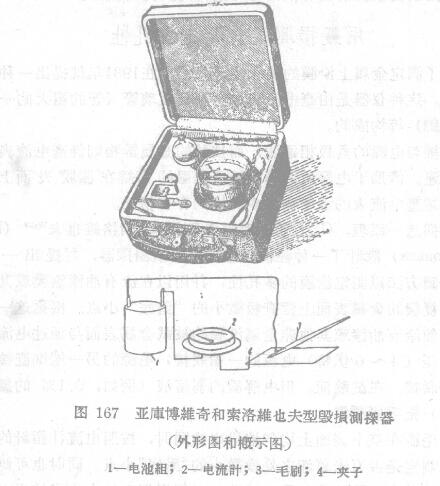

According to this principle, Yakubovich and Soloviev designed a portable instrument-a damage Detector, and proposed a simple electrical measurement method to measure the porosity of the coating film, and used it to test the porosity of the coating film. Detect tiny "breakout" spots on metal surfaces with paint coatings or other non-metallic coatings. According to this method, the tested metal surface coated with paint or other non-metallic coatings is connected to one end of a low-voltage (4-6 volt) power supply through an ammeter; the other end of the power supply is directly connected to a soft brush. Before the test, wet the brush with a weak solution of electrolyte (for example, 0,1 %. Vaporization passivation solution).

While the brush conducts electricity evenly over the entire surface, determine whether there are unpainted areas or tiny "bottomed" spots according to the inclination of the current juice pointer. At the same time, the approximate number of such small spots on the surface can also be measured. For this reason, the sensitivity of the galvanometer indication must be corrected according to the point size. If the bristles are close to the metal, the indication of the galvanometer will increase as the brush approaches the exposed metal. (Related instrument: Ion Meter)

The schematic diagram and schematic diagram of the interior damage Detector are shown in accompanying drawing 167.

Goncharov used this damage Detector in determining the porosity of paint films specially designed for the study of stresses in machine parts, and suggested that the distribution of stresses in metallic workpieces be studied extensively by means of the test method of paint films. Use this device.

In order to measure the porosity of thicker coatings, a high-frequency Detector (related instrument: ultrasonic Thickness Gauge) was proposed. In this instrument, an electrode (for example, a metal brush) around which becomes a high-frequency high-voltage electric field is used as a pore finder. The appearance of sparks on the metal surface indicates damage and exposure of the coating film.