Photoresist film is a functional film widely used in various fields and plays an important role in photosensitive materials. They are often used in photolithography processes as an anti-pattern transfer layer to protect the photoresist from light. Coating technology plays a vital role in the preparation of photoresist films, and small coaters provide a reliable solution for efficient and precise coating.

1. Application fields of photoresist film

Photoresist films play an important role in semiconductor manufacturing, optoelectronics, microelectronics, biomedicine, nanotechnology and other fields. In the semiconductor industry, they are often used in photolithography processes to help define tiny structures on chips. In the field of optoelectronics, they are used in the manufacture of liquid crystal displays, organic light-emitting diodes (OLEDs) and other optoelectronic devices. In biomedicine, photoresist films are used in the preparation of biochips and microfluidic systems. In the field of nanotechnology, they can be used for the preparation and characterization of nanostructures.

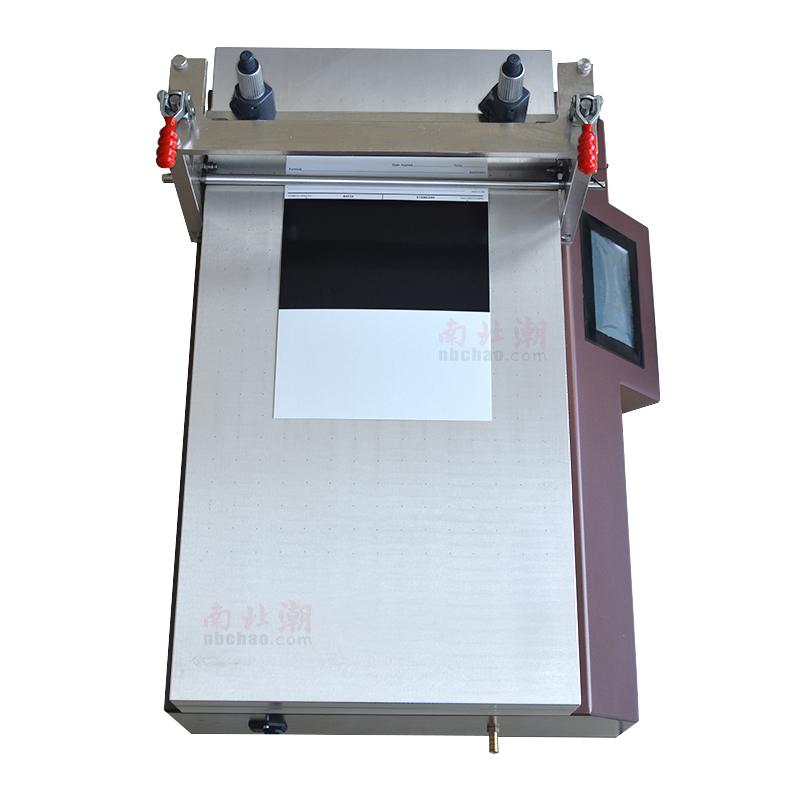

2. Characteristics of small coating machines

Small coaters usually have the characteristics of small size, easy operation and high coating accuracy. They are suitable for small-scale laboratories or small and medium-sized production environments, and can meet application scenarios with high requirements on coating quality and coating thickness. Small coaters usually use a variety of coating methods, such as roller coating, blade coating, spray coating, etc. You can choose the appropriate coating method according to your needs.

3. Application options of small coaters in photoresist film preparation

3.1 Roller coating method

Roller coating is a simple and effective coating method often used to coat uniform films. When preparing a photoresist film, a small roller coater can be used to coat the photoresist onto the substrate surface. By controlling the coating pressure, coating speed and viscosity of the coating liquid, precise control of the coating thickness can be achieved, resulting in a high-quality photoresist film.

3.2 Blade coating method

The blade coating method is a commonly used coating method and is suitable for scenarios that require high coating thickness and surface flatness. When preparing a photoresist film, a small blade coater can be used to apply the paint to the surface of the substrate, and then the excess paint can be scraped off with a blade to obtain the required coating thickness and smooth surface. Spend.

3.3 Spray coating method

The spray coating method is a flexible and efficient coating method, suitable for scenes that require high coating uniformity and high coating speed. When preparing a photoresist film, a small spray coater can be used to spray the coating onto the substrate surface in the form of a spray, and then by controlling the spraying parameters such as spraying distance, spraying angle and spraying pressure, the coating can be Precise control of thickness and coating uniformity.

4. Conclusion

Small coaters have broad application prospects in photoresist film preparation. They can meet the requirements for coating quality and coating thickness in various application scenarios, and provide reliable technical support for the preparation of photoresist films. With the continuous advancement of science and technology, it is believed that small coaters will play an increasingly important role in the field of photoresist film preparation.