Pre-coated coil coating is a coating that has been applied to the surface of the coil during the manufacturing process. It is usually used in construction, home appliances and other fields. In order to ensure that the quality and performance of pre-coated coil coatings meet the requirements, mechanical performance testing is required. This article will introduce in detail the mechanical property testing methods of pre-coated coil coatings.

First, the panel manufacturing requirements will vary depending on the type of pre-coil coating. For solvent-based and water-based pre-coated coil coating products, test panels are usually prepared using the wire Bar Coater drawdown method. According to the standard requirements, the dry coating thickness of the primer is 5 μm7 μm, the dry coating thickness of the back paint is 5 μm8 μm, and the dry coating thickness of the topcoat is determined according to different situations. The drying conditions of the coating film are provided by the coating supplier, and the coating thickness needs to be tested in accordance with relevant standards. For powder-type pre-coated coil coating products, the plate making requirements are to use high-voltage electrostatic Spray Gun equipment to spray the plate on the treated substrate, and then solidify according to the curing conditions provided by the coating supplier.

Next is the specific method of mechanical performance testing. The first is the reverse impact test. According to the corresponding standards, the impact test is carried out on the back of the test plate, using a spherical punch with a diameter of 15.9 mm for impact. After the impact, use transparent pressure-sensitive tape to stick to the surface of the coating deformed by the impact, and quickly tear it off. Finally, use a magnifying glass to check whether the coating is peeling off. The result is expressed as the maximum impact energy at which the coating does not peel off.

Followed by the T-bend test, different detection methods are used according to different types of coatings. For solvent-based and water-based pre-coated coil coatings for construction, as well as other types of solvent-based and water-based pre-coated coil coatings, it is necessary to check whether there is coating peeling off in the deformation area, and the result is expressed as the minimum T-bend value without coating peeling off at the bend. . For solvent-based and water-based pre-coated coil coatings for home appliances, and powder-based pre-coated coil coatings for construction and home appliances, it is necessary to check whether there is coating cracking in the deformation area. The result is the minimum T without coating cracking at the bend. Bend value expressed.

In addition, there are cupping test and scratch test. The cupping test is performed according to the corresponding standards by applying pressure on the coating surface and quickly tearing off the transparent pressure-sensitive tape, and then using a magnifying glass to check whether the coating is peeling off. The result is expressed as the maximum indentation depth at which the coating does not peel off. . For the cross-hatch test, a manual multi-edged cutting tool is used to cut, and transparent pressure-sensitive tape is used to remove the loose coating film in the cut area.

The last step is the scratch resistance test, which is conducted using scratch needle A according to relevant standards.

Reverse impact test:

Use a spherical punch with a diameter of 15.9 mm to impact the back of the test plate.

After the impact, stick a transparent pressure-sensitive tape on the deformed coating surface, quickly tear it off and use a magnifying glass to check whether the coating is peeled off. The results are expressed in terms of the maximum impact energy.

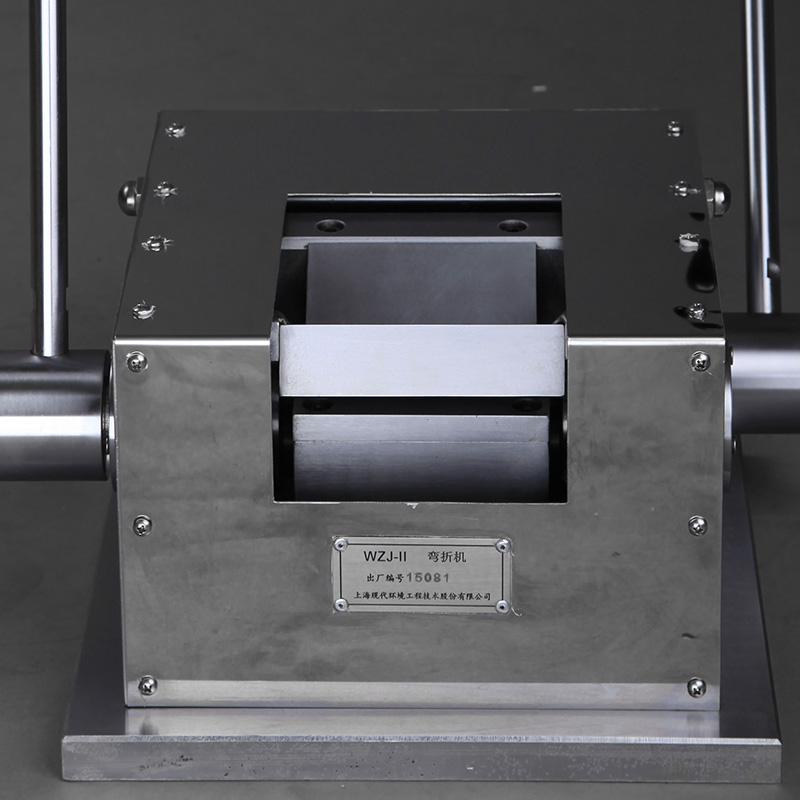

T-bend test:

Different detection methods are used according to different coating types, and the results are expressed as the minimum T-bend value without coating peeling or cracking at the bend.

Cupping test:

Apply pressure to the coating surface and quickly peel off the transparent pressure-sensitive tape, then use a magnifying glass to check whether the coating has peeled off. The result is expressed as the maximum indentation depth.

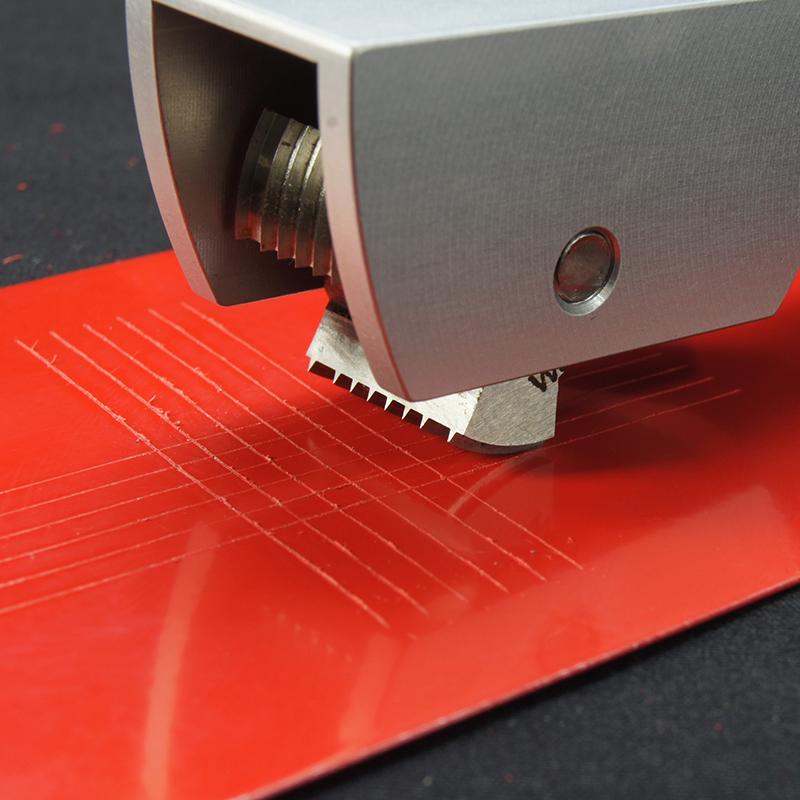

Cross-hatch test:

Use a manual multi-edged cutting knife to cut, then use clear pressure-sensitive tape to remove loose film from the cut area.

Scratch resistance test:

Test using needle A according to relevant standards.

To sum up, the mechanical performance testing of pre-coated coil coatings involves many aspects, including test methods such as reverse impact, T-bend, cupping, scratches and scratch resistance. These test methods can comprehensively evaluate the performance of the coating. quality and performance, ensuring its good durability and stability during use.