introduction

As people's demand for clean energy continues to increase, lithium-sulfur batteries have been widely researched and applied as a potential high-energy-density battery. In lithium-sulfur batteries, carbon materials are used as carriers and conductive agents and play a key role. Preparing high-quality carbon material films is crucial to improving the performance of lithium-sulfur batteries. As an important film preparation equipment, small precision coating machines play an important role in carbon material film production. This article will discuss the application of small precision coaters in carbon material film production for lithium-sulfur batteries and its impact on battery performance.

Application of coating technology in battery field

In the preparation process of lithium-sulfur batteries, carbon materials are widely used as electrode materials to improve the conductivity and stability of the battery. Preparing carbon material films is one of the key steps in the preparation process of lithium-sulfur batteries. Traditional coating technologies, such as roller coating, blade coating, etc., have problems with coating uniformity and thickness control. The small precision coating machine can more accurately control the coating thickness and coating uniformity, providing new possibilities for the preparation of carbon material films.

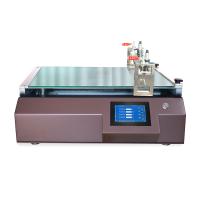

Advantages of small precision coating machines

The small precision coating machine can accurately control the coating thickness and coating speed to ensure that the film preparation process is stable and controllable. It has a high coating speed and can quickly prepare carbon material films and improve production efficiency. Small precision coating machines can achieve high coating uniformity and ensure stable film quality. It has flexible process adjustment function and is suitable for the preparation needs of different carbon material membranes.

Practical application cases

In actual production, small precision coating machines have been widely used in the film production process of carbon materials for lithium-sulfur batteries. By precisely controlling coating parameters, such as coating speed, coating thickness, and temperature, the preparation of high-quality carbon material films can be achieved. Experimental results show that the carbon material film prepared by a small precision coating machine has high conductivity and cycle stability, providing an effective way to improve the performance of lithium-sulfur batteries.

How to make film

In the film production process of carbon materials for lithium-sulfur batteries, a small precision coater is a key film preparation equipment. The following is the basic operation method of using a small precision coating machine to film carbon materials for lithium-sulfur batteries:

1. Preparation:

Carbon material preparation: Prepare the carbon materials needed to prepare the membrane to ensure stable quality and high purity.

Coater preparation: Inspect and clean the small precision coater to ensure the equipment is in good condition.

2. Set coating parameters:

Coating speed: Control the coating speed of the coater as needed, usually adjusted according to production requirements and required film thickness.

Coating thickness: Set the coating thickness of the coating machine according to actual needs, which can usually be achieved by adjusting the coating roller or coating head of the coating machine.

Temperature control: Maintaining a constant temperature during the coating process contributes to the uniformity and quality of the film. Temperature control is carried out according to material characteristics and process requirements.

3. Prepare the membrane substrate: Place the membrane substrate on the workbench of the coater, making sure the surface is clean and secured to prevent movement.

4. Coating operation: Coating the pre-prepared carbon material on the membrane substrate can be achieved by coating roller or spraying. Control the coating speed and thickness of the coater to ensure that the carbon material is evenly coated on the film substrate.

5. Drying treatment: After the coating is completed, place the coated film substrate in a drying chamber or heating equipment for drying treatment to ensure that the film is completely dry.

6. Quality inspection: Conduct quality inspection on the prepared carbon material film, including inspection of film thickness, coating uniformity, surface quality and other indicators.

in conclusion

Small precision coating machines have important application value in the production of carbon material films for lithium-sulfur batteries. By precisely controlling coating parameters, small precision coaters can prepare high-quality carbon material films and improve the performance and cycle stability of lithium-sulfur batteries. In the future, with the continuous advancement and development of coating technology, small precision coating machines will play a more important role in the field of lithium-sulfur batteries.