In the fields of industrial production and scientific research, the processing of gases and steam often requires the use of Vacuum Pumps to create a vacuum environment. As a key equipment for efficient gas and steam processing, powder Vacuum Pump plays an important role in various application scenarios. This article will deeply explore the principles, applications and future development trends of powder Vacuum Pumps.

Principle analysis

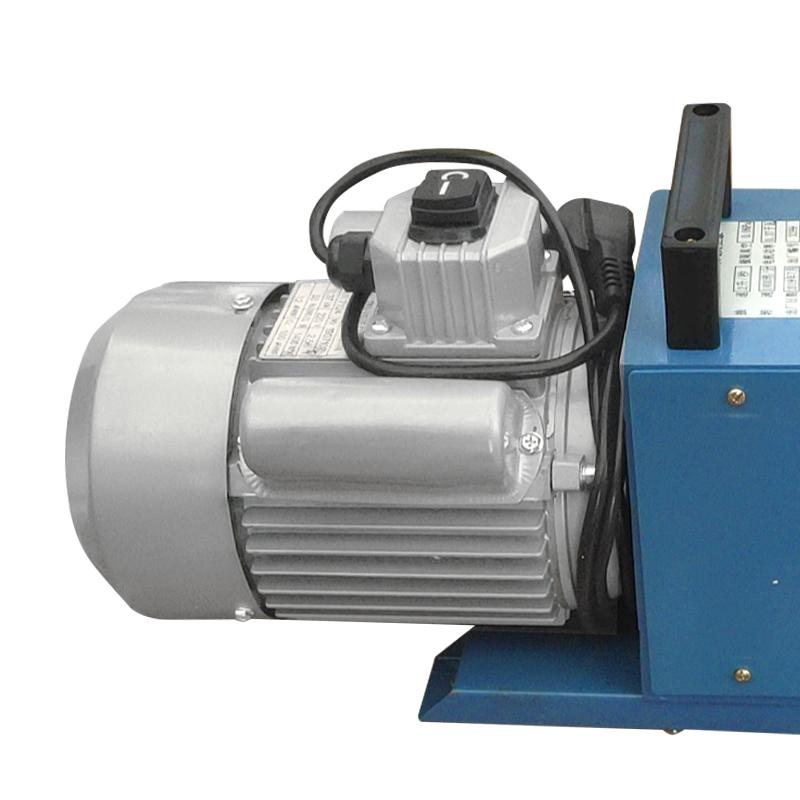

A powder Vacuum Pump is a device that moves gas molecules through mechanical vibration or rotation to achieve vacuum extraction. The main principle is to use a high-speed rotating impeller or vibration device to cause gas molecules to generate kinetic energy under the action of the impeller or vibrator, and then be discharged from the Vacuum Pump system, thereby realizing the extraction of gas and steam. Its basic components include impeller, vibration device, air inlet, air outlet and vacuum chamber. By controlling the motion state of the impeller or vibration device, efficient extraction of gas and steam can be achieved.

Application areas

Powder Vacuum Pumps are widely used in many fields. First of all, in the field of semiconductor manufacturing, powder Vacuum Pumps are often used in the production process of semiconductor devices to extract gases and steam generated during the process to ensure the preparation quality and production efficiency of the devices. Secondly, in the chemical industry, powder Vacuum Pumps are often used to process gases and steam during chemical reactions to improve reaction efficiency and product purity, and ensure process safety and environmental friendliness. In addition, in the field of laboratory scientific research, powder Vacuum Pumps are also widely used in experiments in physics, chemistry, biology and other disciplines to create vacuum environments and conduct various experimental studies.

With the continuous advancement of science and technology, powder Vacuum Pumps are also constantly undergoing technological innovation and improvement. In the future, with the development of materials science, control technology and other fields, powder Vacuum Pumps will become increasingly intelligent and efficient. By using advanced materials and control systems, the Vacuum Pump system can be automatically monitored and adjusted to improve extraction efficiency and stability. In addition, with the increasing awareness of energy conservation and environmental protection, powder Vacuum Pumps will also focus on reducing energy consumption and reducing environmental pollution. In the future, powder Vacuum Pumps will pay more attention to energy efficiency optimization and environmental protection performance, and contribute to sustainable development.

Conclusion

As a key equipment for efficient gas and steam processing, powder Vacuum Pump plays an important role in industrial production and scientific research. By in-depth understanding of its principles, strengthening technological innovation, and continuously improving the level of intelligence and energy utilization efficiency, we can better meet the needs of industrial production and scientific research experiments for vacuum environments, and promote the development and progress of related fields. It is believed that in the near future, with the continuous advancement of science and technology, powder Vacuum Pumps will play a more important role in various fields and contribute to the promotion of industrial development and technological innovation.