As far as the galvanized layer Thickness Gauges currently on the market are concerned, no matter which brand of galvanized layer Thickness Gauge is used, its operation requires the following steps.

(1) Zero adjustment, that is, zero adjustment on a specific zero board, or zero adjustment on the original substrate to be measured.

(2) According to the different measurement ranges of the samples to be tested, calibrate with appropriate standard test pieces.

Precautions related to galvanized layer Thickness Gauge

(1) Before measurement, it must be zero-adjusted on the uncoated substrate whose base material, thickness, measurement area, and surface curvature radius are all the same as the sample to be tested, so as to ensure the accuracy of the measurement ;

(2) In order to ensure the accuracy of the readings, the interval between each measurement is a few seconds; the measurement of the coating on the sandblasting and shot peening surface should be calibrated strictly according to the calibration steps in the manual;

(3) Do not pull or bend the measuring head wire, so as not to break the wire or cause poor contact and no signal;

(4) When there is acid, alkali solution or wet substance on the surface to be measured, it needs to be cleaned to remove these acid, alkali solution or wet sundries, so as not to damage the probe;

(5) When measuring, make the axis of the probe perpendicular to the surface of the sample to be tested;

(6) Generally, the time interval between each measurement should be greater than 3 seconds.

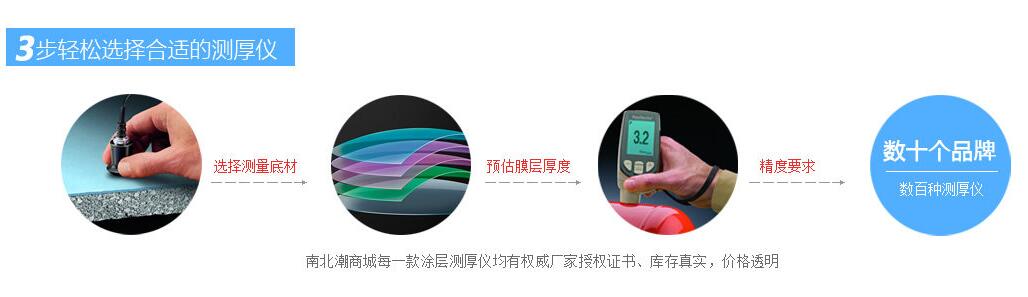

For how to choose the galvanized layer Thickness Gauge, please click on the selection tool: http://tool.nbchao.com/thickness/